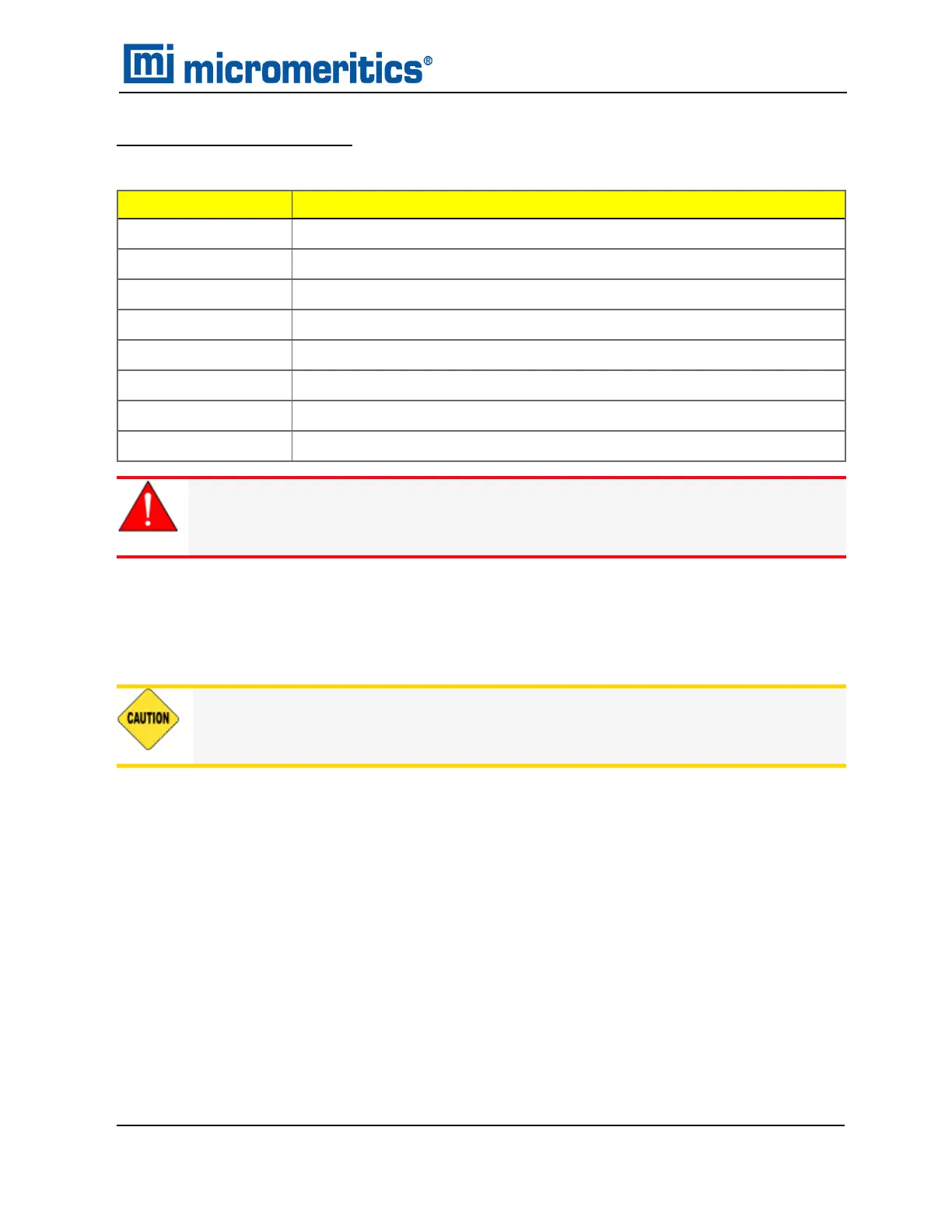

Connect a Gas Cylinder

Analyzer Series

Gauge should indicate

3Flex

15 psig (103 kPag)

AccuPyc

25 psig (172 kPag)

ASAP

15 psig (103 kPag)

AutoChem

15-18 psig (103 - 124 kPag)

AutoPore

50-60psig (345 - 404 kPag)

Gemini

15-18 psig (103 - 124 kPag)

MICSASII

15-20 psig (103-138 kPag)

TriStar

15-18 psig (103 - 124 kPag)

Regulator Pressure Settings

Exceeding the maximum recommended air pressure could cause personal injury or dam-

age the instrument.

1. Use an appropriate cylinder wrench to remove the protective cap from the replacement gas

cylinder. Place the protective cap in a secure location. It will be needed to recap the gas cyl-

inder when it is depleted and replaced.

2. Attach the gas regulator to the gas cylinder connector. Hand tighten the nut, then use an

appropriate wrench to tighten an additional 3/4 turn.

Over-tightening the fitting may cause a leak.

3. Check for leaks at the high pressure side of the regulator and in the connector.

a. Turn the regulator control knob fully counter-clockwise.

b. Slowly open the gas cylinder shut-off valve, then quickly close it.

c. Observe the pressure on the high pressure gauge for approximately one minute:

n If the pressure is stable, proceed with the next step.

n If the pressure decreases, tighten the regulator connector nut until it becomes stable.

If the pressure does not remain stable, remove the regulator and clean all contacts at

the regulator connection, then reinstall the regulator.

4. Purge the lines and set the regulator pressure.

a. If the gas line is not connected to the regulator and the instrument connect it now.

b. Fully open the gas bottle shut-off valve and the gas regulator shut-off valve.

c. Under manual control, open the fill, expand, and vent val

Replace a Gas Cylinder

AccuPyc II 1345 Operator Manual

134-42851-01 (Rev A) — Jan 2021

12 - 13

Loading...

Loading...