Chapter 8 Troubleshooting

241

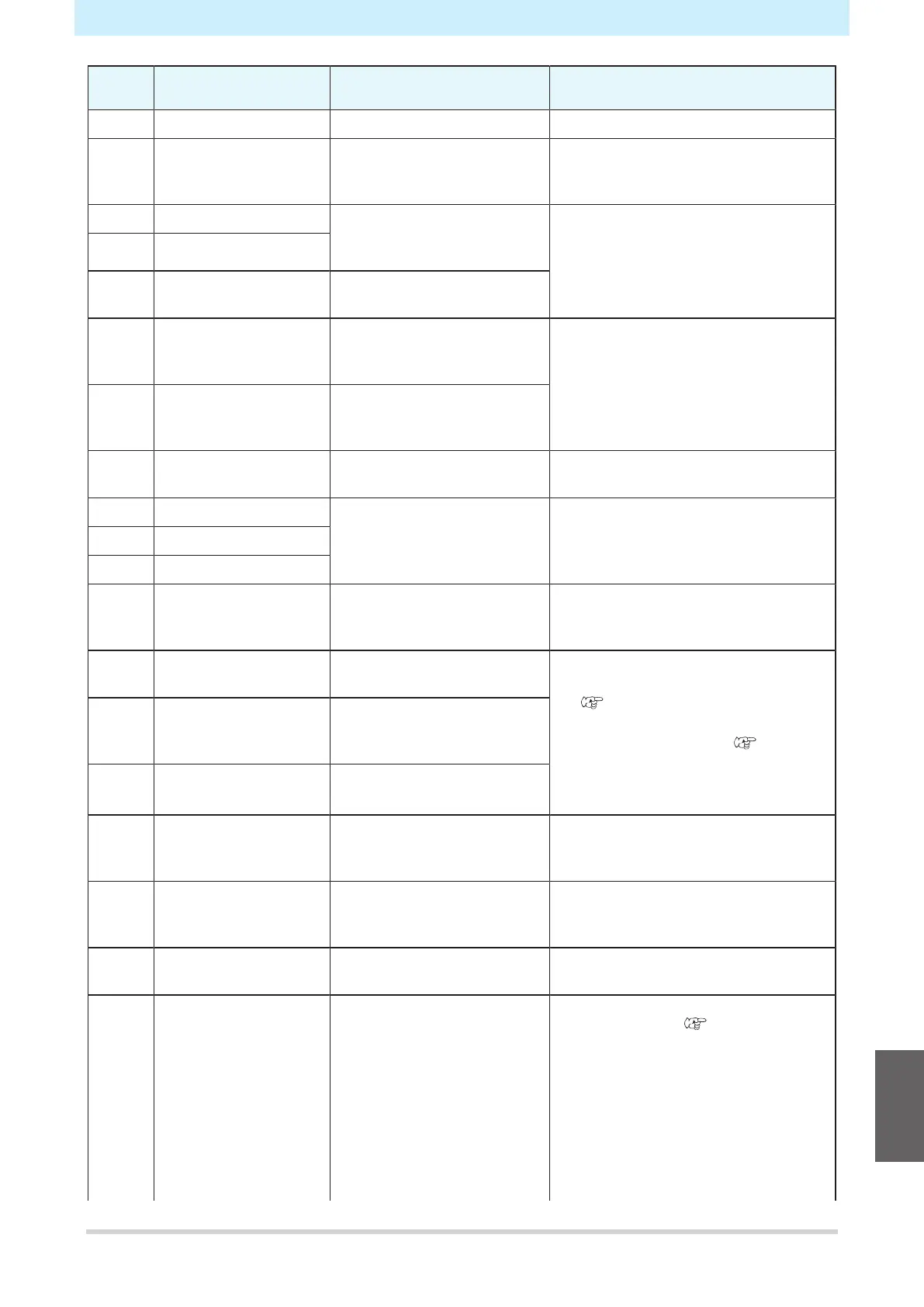

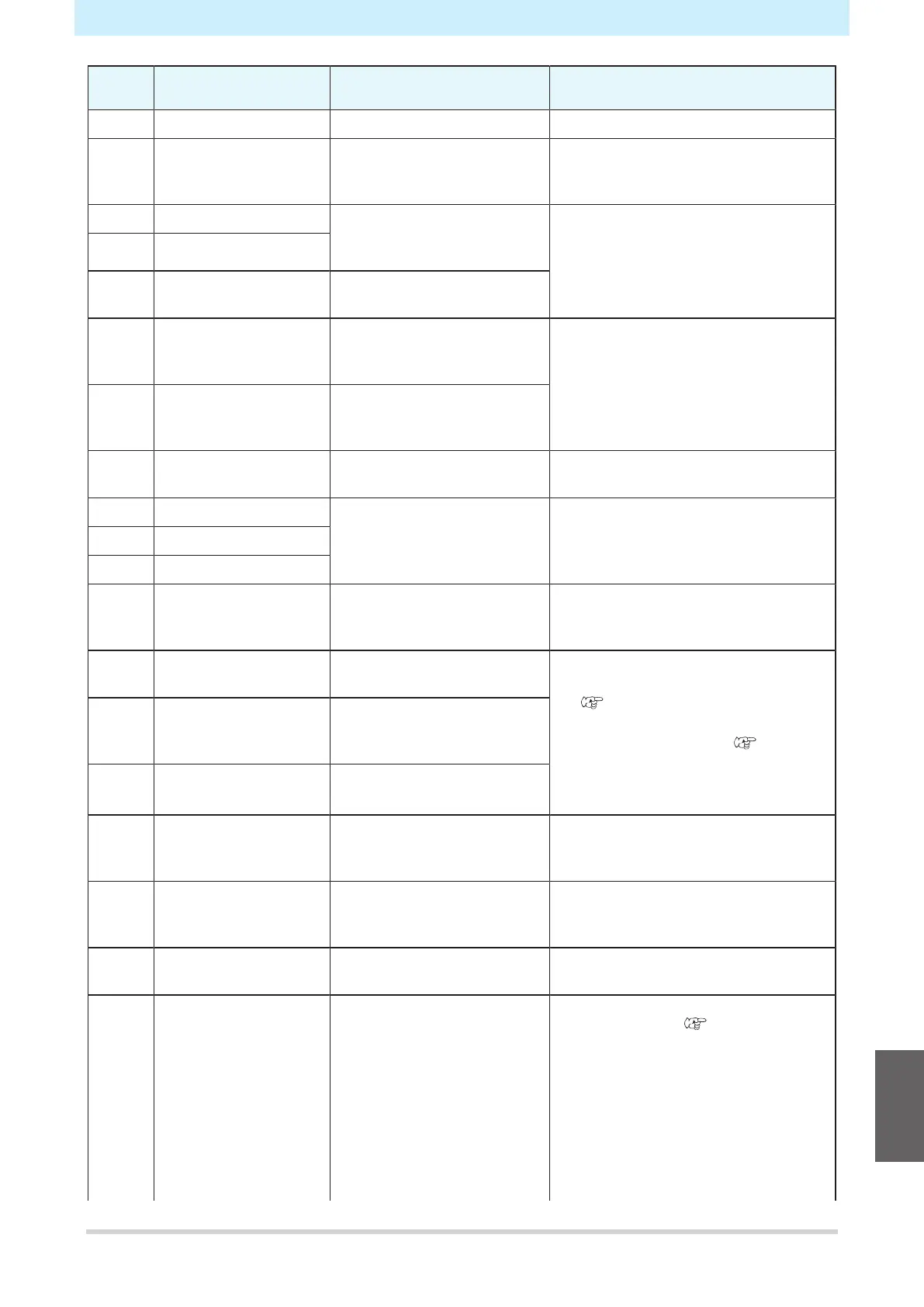

Error

number

Message Cause Corrective action

b1d BaseIO PCB V24-A

b1e PCB BaseIO-F** • The Base IO PCB fuse

blow was detected.

• The fuse must be replaced. Contact

your local distributor, our sales

office, or service center.

b32 INKCT PCB V2R5 • A problem was detected

with the ink supply PCB

power supply.

• Turn off the power on the machine

and turn it on after a while.

b33 INKCT PCB V3R3

b3f BaseIO Unconform • The PCB could not be

detected.

b48 PCB HDCE* • A communication error

was detected between the

boards.

• Turn off the power on the machine

and turn it on after a while.

b49 PCB HDCE-

VHVFET[12]

• A problem was detected

with the HDCE PCB

power supply.

b4a PCB HDCE*-F* • A blown fuse on the

HDCE PCB was detected.

• Contact your local distributor, our

sales office, or service center.

b4b HDCE* PCB V1R2 • A problem was detected

with the HDCE PCB

power supply.

• Turn off the power on the machine

and turn it on after a while.

b4c HDCE* PCB V2R5

b4d HDCE* PCB V3R3

b53 XY slitter

No slider PCB

• The XY slitter CG

common slider PCB could

not be detected.

• Turn off the power on the machine

and turn it on after a while.

C10 Command • Received a code other

than a COMMAND code.

1. Clear the data and resend.

2. Check the USB/Ether cable connection.

"Connecting a PC to the

Product"(P. 39)

3. Use a compatible cable.

"Connecting a PC to the Product"(P. 39)

4. Turn off the power on the machine and

turn it on after a while.

C11 Parameter • Received parameter

outside numerical value

range

C12 Device • Received an invalid

device control command.

C31 No Data • "COPY" was executed,

but no data is saved to the

receive buffer.

• Transmit the same data once more.

C32 DataTooBig • The received data is too

big for multiple sheet

cutting.

• Change the data size.

C33 Sheet Size • The sheet is too short in

the feed direction.

• Use a longer sheet.

C36 Mark Detect • Unable to detect register

marks

1. Check to confirm the register marks are

placed properly. "Register

Marks"(P. 112)

2. Load the uncurled media.

3. Check the mark detection start position.

4. Check to confirm the register marks are

black and printed on a white

background.

5. Check to confirm the area between the

register marks is clean and free of print.

8

Loading...

Loading...