OPERATION

© 2014 Mold-Masters (2007) Limited. All Rights Reserved.

Revised 1 Oct, 2014

6-48

6.30 How to use the IO5 card for Remote

Tool Selection

The IO5 offers all the same functions of the 4-channel input/output

card along with some extra input/output functions that enable remote

tool loading. These extra functions connect to the remote machine us-

ing either a HAN16A connector or an AMP 183040 circular connector.

The connector pins are congured according to the table below.

Pin Function

1 “tool load” signal from molding

machine to ask console to load tool

2 address 1

3 address 2

4 address 4

5 address 8

6 address 16

7 address 32

8 address 64

9 address 128

10 spare

11 “Tool loaded

signal” from

console to

molding machine

Normally-Open

12 Common

13 Normally-Closed

14 GND

Static or Dynamic Tool Load

The IO5 can be used in two ways to enable remote tool loading.

The static method is enacted by simply connecting appropriate “load”

and “tool ID” pins to ground. The tool is loaded and feedback is ig-

nored.

The dynamic method sends a change tool command by connecting

the “load” and “tool ID” pins to ground – it then watches to see that

a tool has been satisfactorily loaded and then ends the tool load

process. It is also free to repeat the operation and load another tool

should the need arise.

Static Remote Tool Load Process

If you want to load a tool without receiving console feedback then you

can simply short appropriate pins together…

Load Tool 10 – connect, “load pin”, and “tool id pins” to ground - con-

nect pins 1, 3, & 5 to 14

Load tool 19 – connect pins 1, 2, 3 & 6 to 14

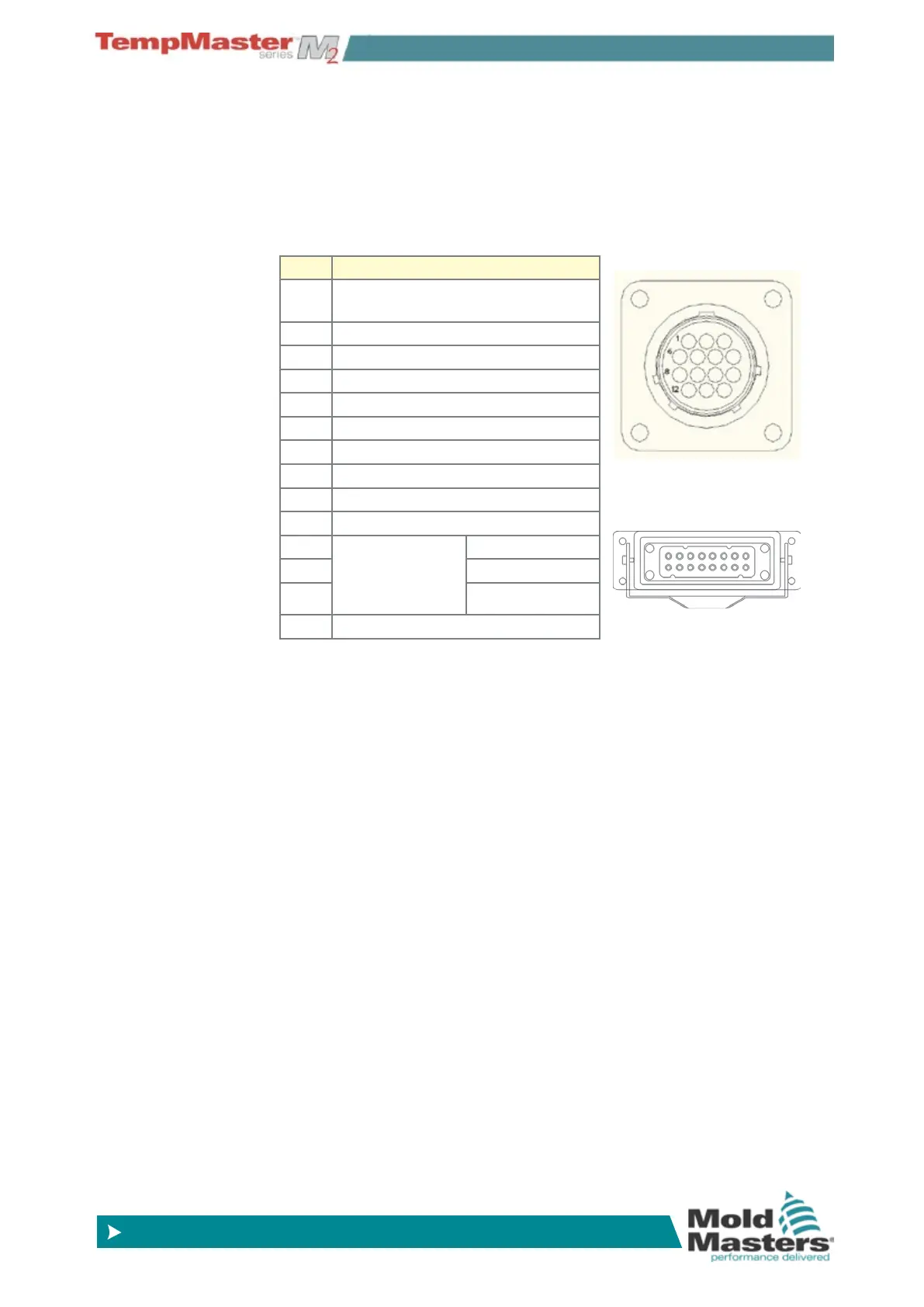

AMP 183040-1Connector

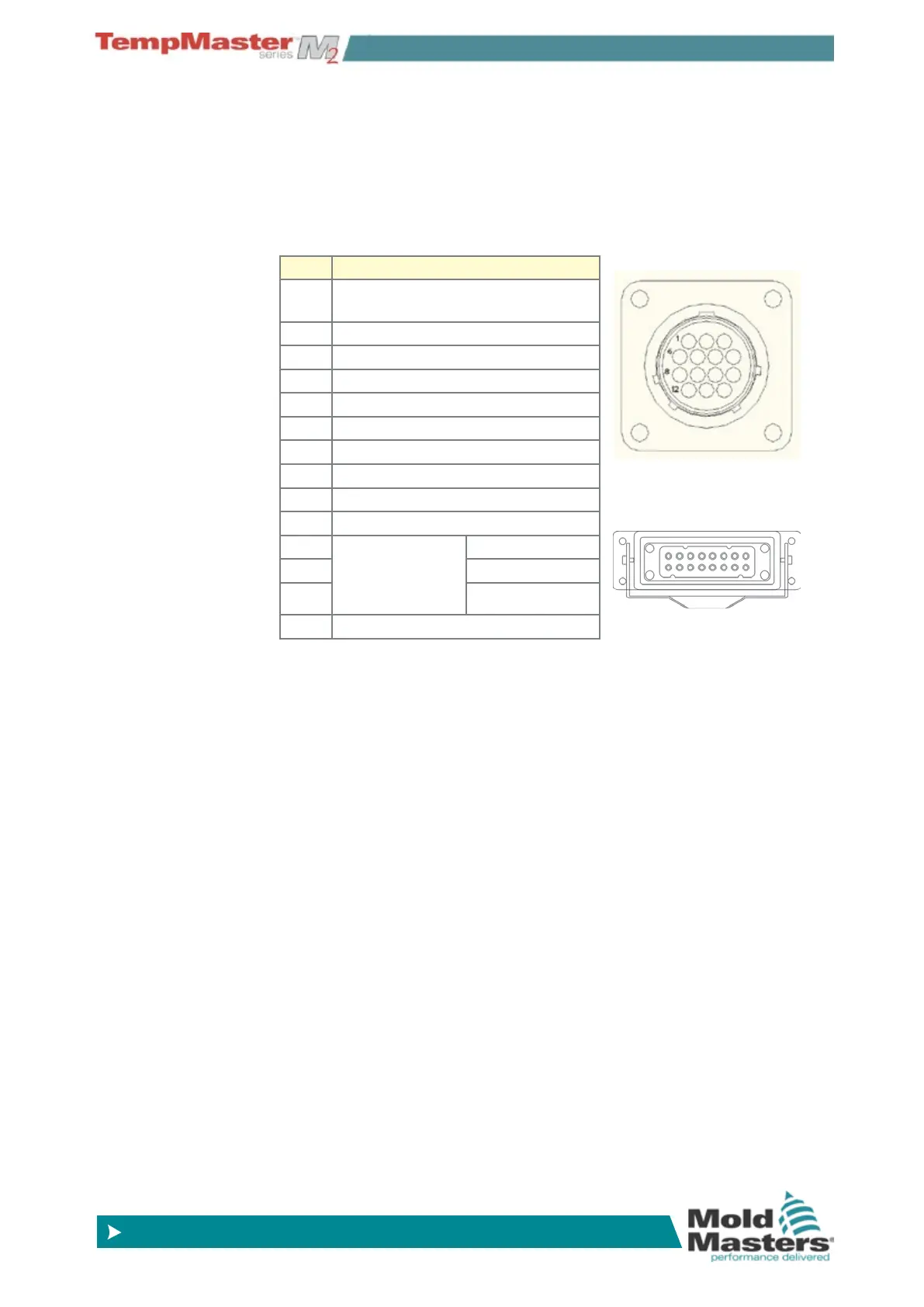

HAN16A Connector

Loading...

Loading...