TROUBLESHOOTING

© 2014 Mold-Masters (2007) Limited. All Rights Reserved.

Revised 1 Oct, 2014

8-1

Section 8 - Troubleshooting

The control system has several features, which provide an early

diagnosis of faults in the control system, the tool heaters and thermo-

couple sensors.

If the system detects any malfunctions, in one or more of the control

zones, then it displays an error message on the main page in place of

a temperature value.

If the system detects any abnormal condition it displays a warning

message in the Main menu.

8.1 Fault and Warning Messages

Any of the following messages may be displayed on the Fault

Indication line:

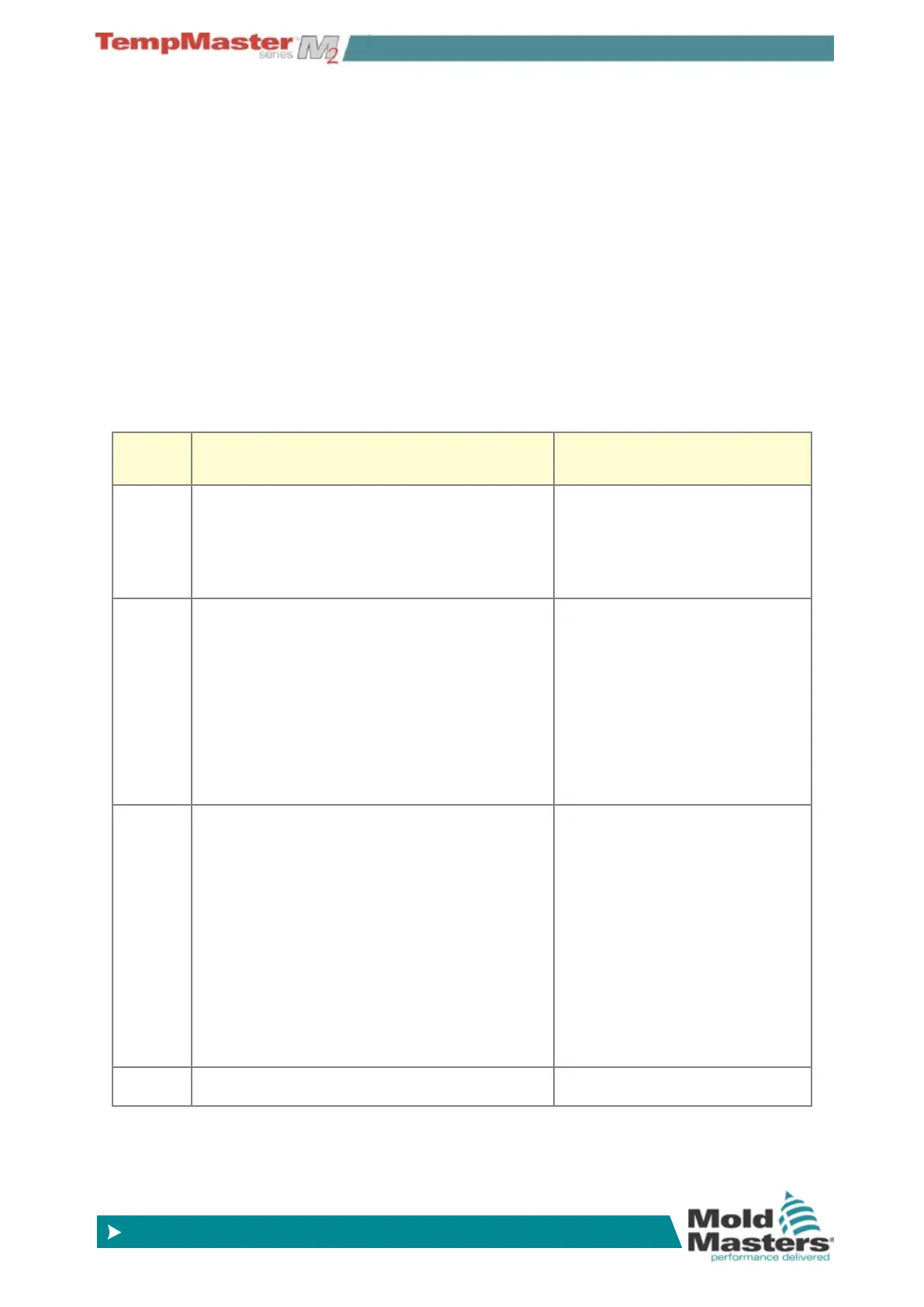

Error

Message

Cause Action

AMPS

The controller is unable to supply the current

requested. (Note: This error message is most likely

to be seen if the particular zone is set as a Spear

type).

Isolate system supply, check loom

and heater wiring continuity. Also,

check the heater resistance against

other known good zones to see

that it is not noticeably higher than

average.

ERR!

Little or no temperature rise has been detected in

that zone. When the console starts to apply power

it expects to see an equivalent heat rise at the ther-

mocouple. If the thermocouple has been trapped

and pinched elsewhere in the tool or cable then it

cannot see the full heat rise that occurs at the tip.

If left uncorrected then there is a danger that the

zone could overheat and damage the tip. Instead

the circuit maintains the output at whatever level it

reached when the monitor circuit detected the fault

and the error message was displayed.

Check thermocouple wiring, it may

be reversed. Heater wiring may

be faulty or element may be open

circuit.

FUSE

The fuse for that zone has failed.

Please Note: A fuse can only fail due to a fault ex-

ternal to the controller. Identify and rectify the fault

before replacing the fuse.

Note: The fuse detection circuit requires a continu-

ous low level current through a high impedance

bleed resistor to maintain the alarm condition. As a

result the load circuit is still connected to the mains

voltage supply and it is not safe to attempt to repair

or replace the fuse without rst isolating the circuit.

If the fuse in question is mounted on a control card

then it is safe to unplug the board in order to isolate

the circuit and replace the fuse on the card.

Replace the fuse with one of the

same rating and type, i.e. High

Rupture Current load fuse. The

blown fuse is located either on the

control card or on the off-board triac

module (If tted).

GND The system has detected an ground fault.

Check your heater wiring for a low

impedance path to ground.

Loading...

Loading...