OPERATION

© 2014 Mold-Masters (2007) Limited. All Rights Reserved.

Revised 1 Oct, 2014

6-49

6.31 Dynamic Remote Tool Load Process

This sequence allows a degree of control and feed-back. The proce-

dure to remotely load another tool (in this example it will be tool 10) is

as follows:

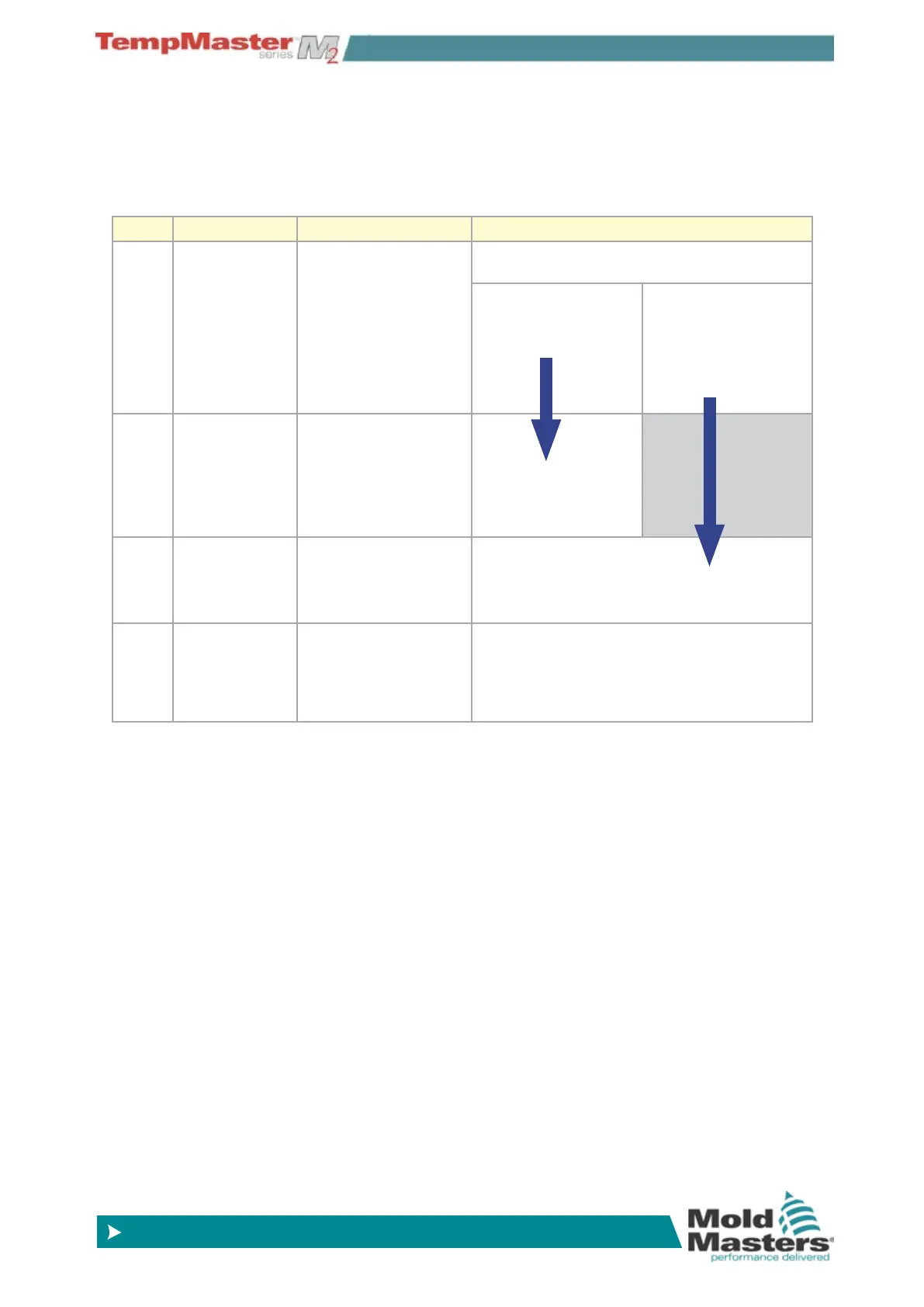

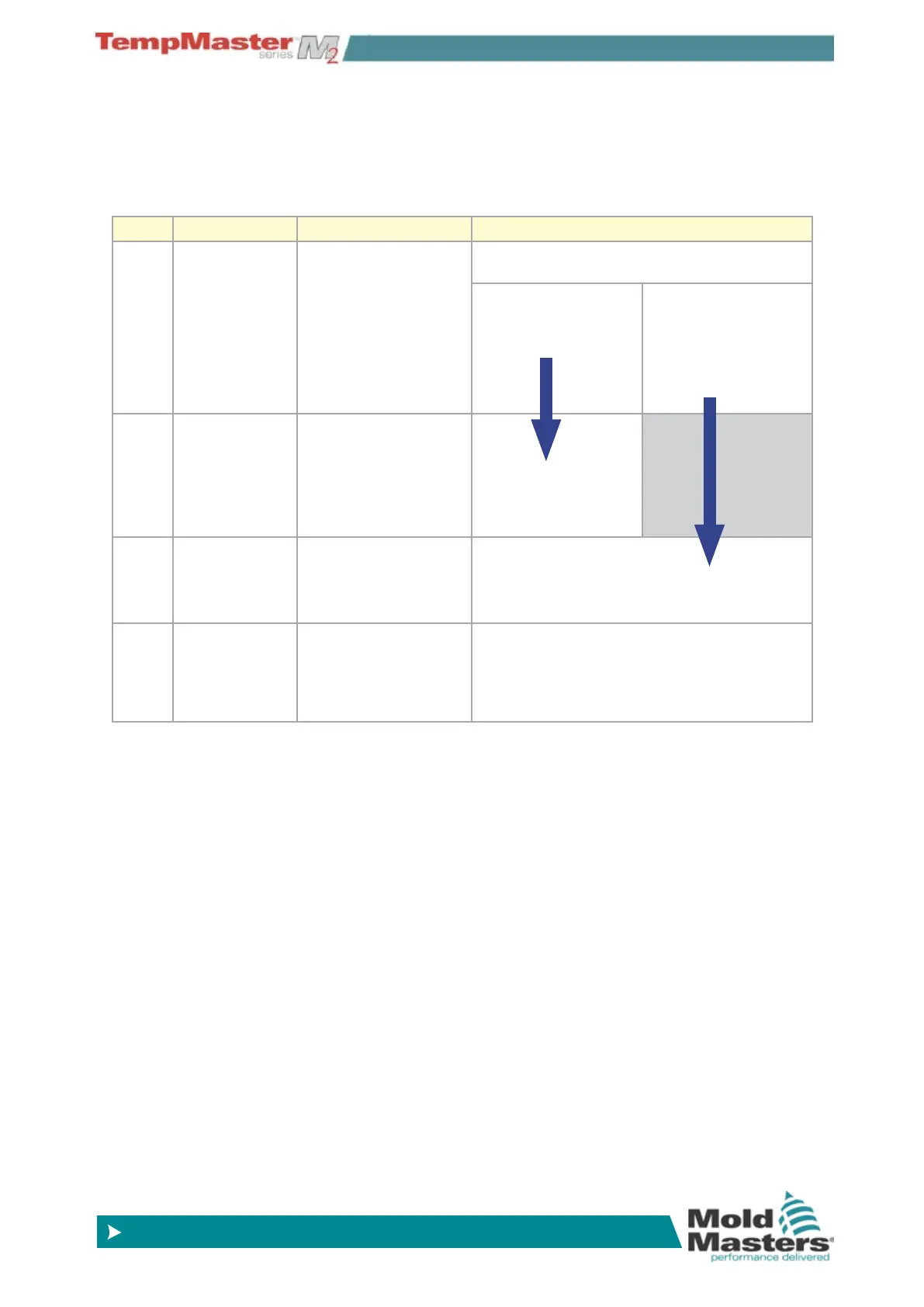

Step Action Remote Machine Local Console

1 Selects a Tool

and Initiates

tool load.

Connects pins 14

(ground) to pins 3 & 5

(address 2+8 = 10) and

pin 1 (“tool load”).

Console checks to see that it has valid tool

settings in that tool bank.

If “no” then there is

no change in “Tool

Loaded “signal.

If yes then it disables

“Tool loaded Signal”

( pins 11& 12 go

“Closed” while pins

12&13 go “Open”).

2 Console

cannot nd any

conguration for

selected tool.

Machine sees that

no tool change has

occurred. It may ag an

error to await operator

intervention.

Process ends.

The Console displays

an error message -

“No Tool Found”.

Process

skips

step 2

and goes

to step 3.

3 Console can

nd a tool and

loads it.

Waits for “Tool Loaded

Signal”.

Loads Tool 10 and indicates process is nished

by enabling “Tool Loaded Signal” (pins 11 &12

go “Open” and pins 12 & 13 go “Closed”).

4 Process Ends. Sees “Tool Loaded

signal” from console

and disconnects Pins1,

3 & 5 from ground (pin

14).

Console loses the “Change Tool” command.

Loading...

Loading...