OVERVIEW

© 2014 Mold-Masters (2007) Limited. All Rights Reserved.

Revised 1 Oct, 2014

4-1

Section 4 - Overview

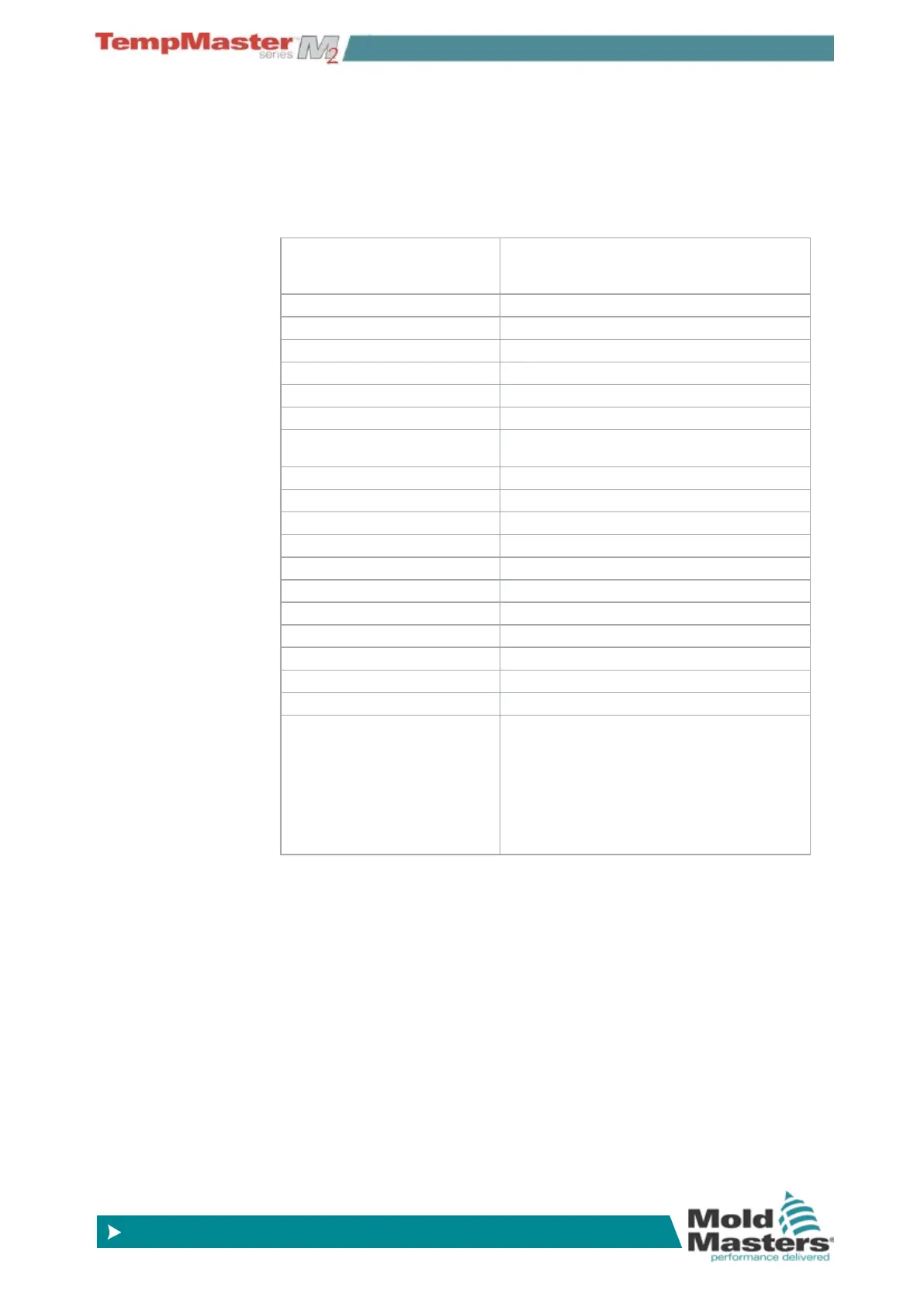

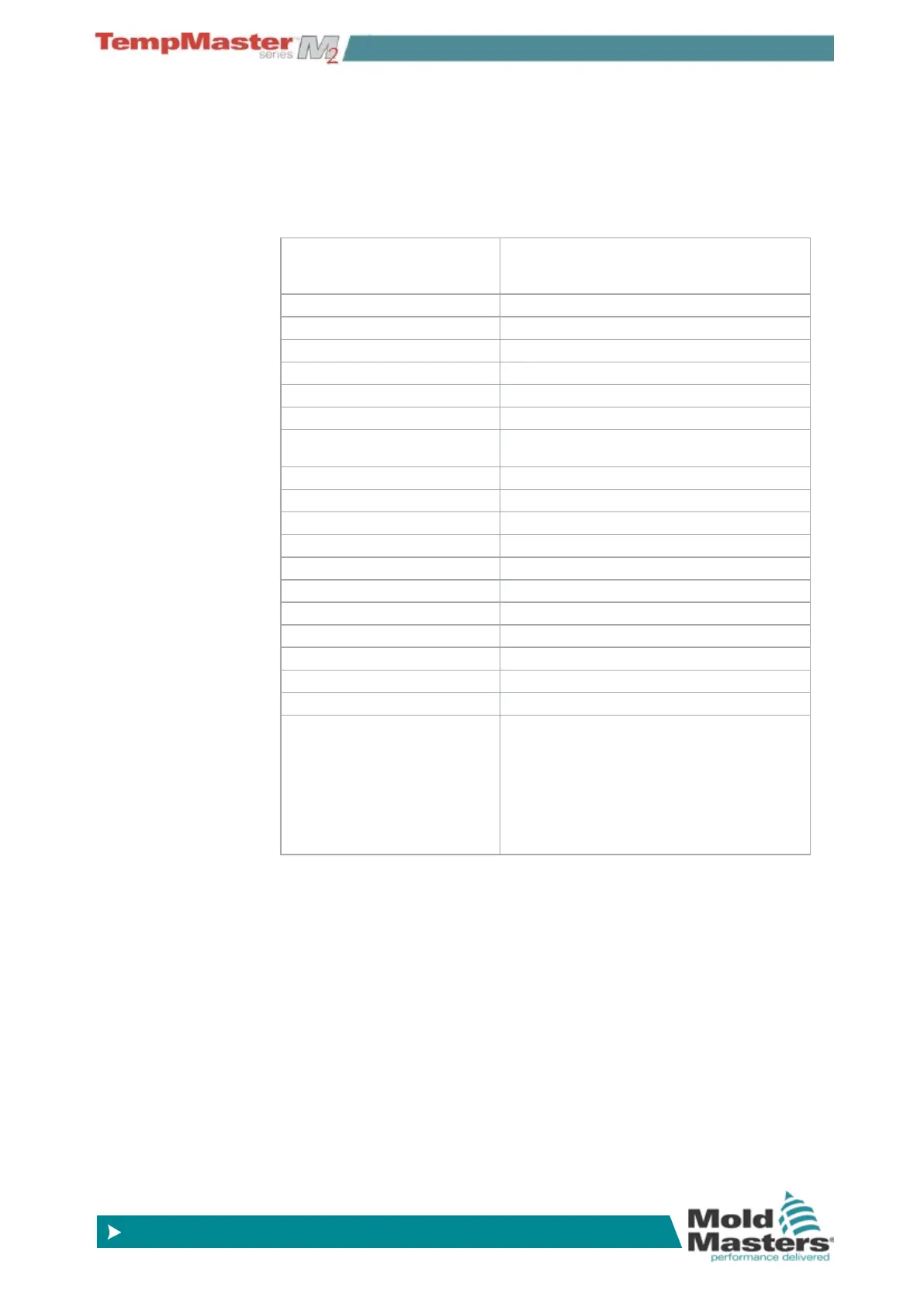

4.1 Specication

The following are general specications. The actual controller/console

supplied may have contractual variations and differ in some specied

options.

Supply Voltage 415Vac 3 phase 50/60Hz with neutral, Other

available include 240/380/400 and 480 volts in

Star or Delta conguration.

Voltage Bandwidth Stable within 20% supply voltage swing

Supply ground-leakage trip 300mA (note: this is for tool protection)

Unit Overload protection Miniature Circuit Breaker

Output overload protection 15A super-quick acting (FF) fuse on both legs

Power output 15A/3600W per zone

Ground Fault Detection 40mA per zone

Thermocouple input Type ‘J’, or type ‘K’

Control Method Self tuning PID

Soft-Start with Auto Tune Unique low voltage method for heater safety

Temperature scale Centigrade (Celsius) or Fahrenheit

Operating Range 0 - 472°C or 32 - 882°F

Control Accuracy +/-1°C

Printer Output Connector USB Port

Data Communications RS-232 serial, DB9 male connector

Communication Protocol SPI, VNC and client over Ethernet

Alarm Output Closing volt-free contacts - 5A max 230V

Remote Input Voltage free pair to signal Boost or Standby

Interface Full colour LCD touch screen (choice of sizes)

Case Details Heavy duty metal cabinet with swing up console

Sizes in mm

M2XS: 310w × 450d × 450h

M2S : 360w × 450d × 800h

M2M: 450w × 540d × 860h

M2L: 450w × 540d × 1330h

Filter Option

In countries where noise across power lines is a concern,

Mold-Masters recommends that you t the model 63AYC10B in-line

lter which is supplied by TC Connectivity.

Loading...

Loading...