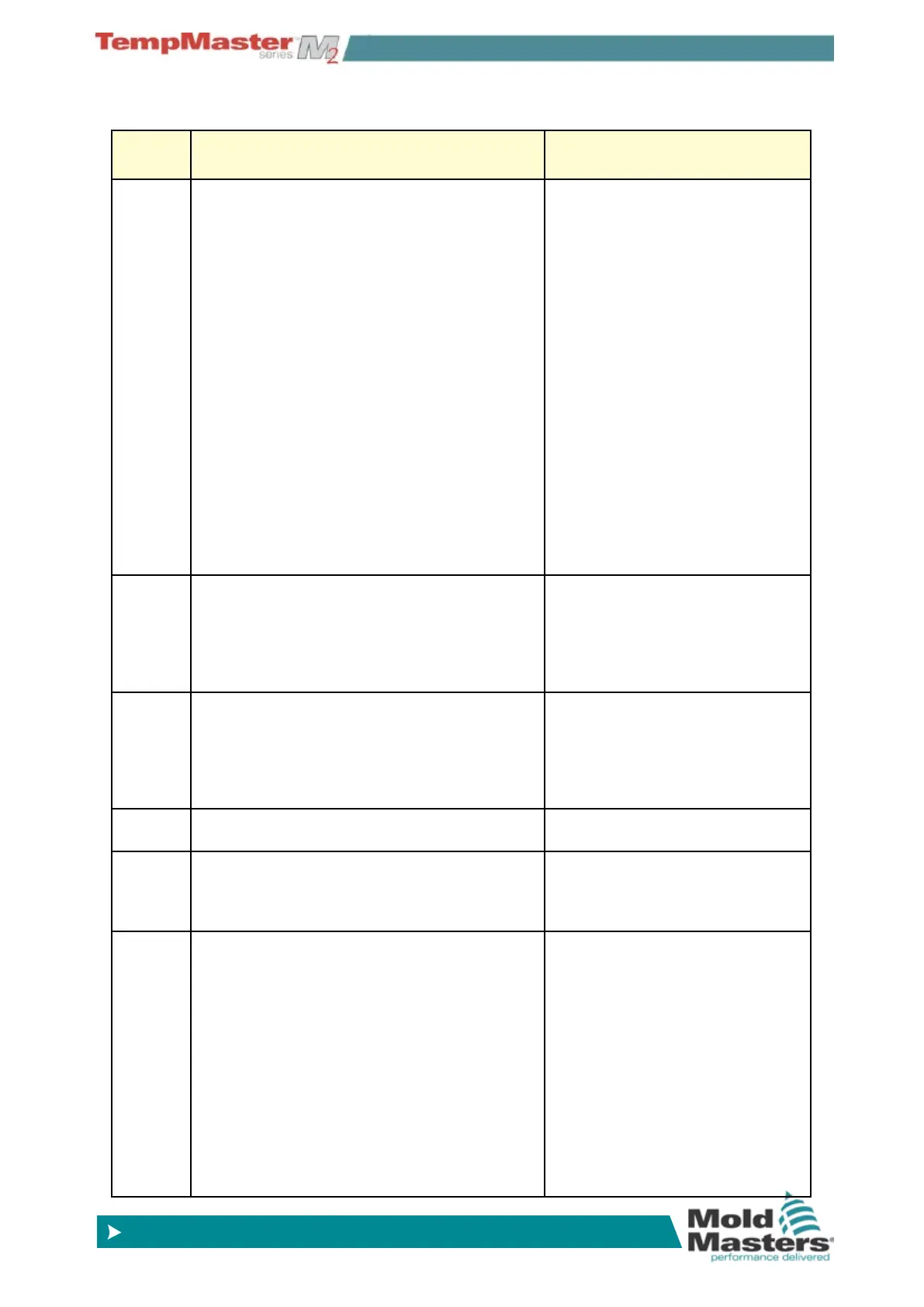

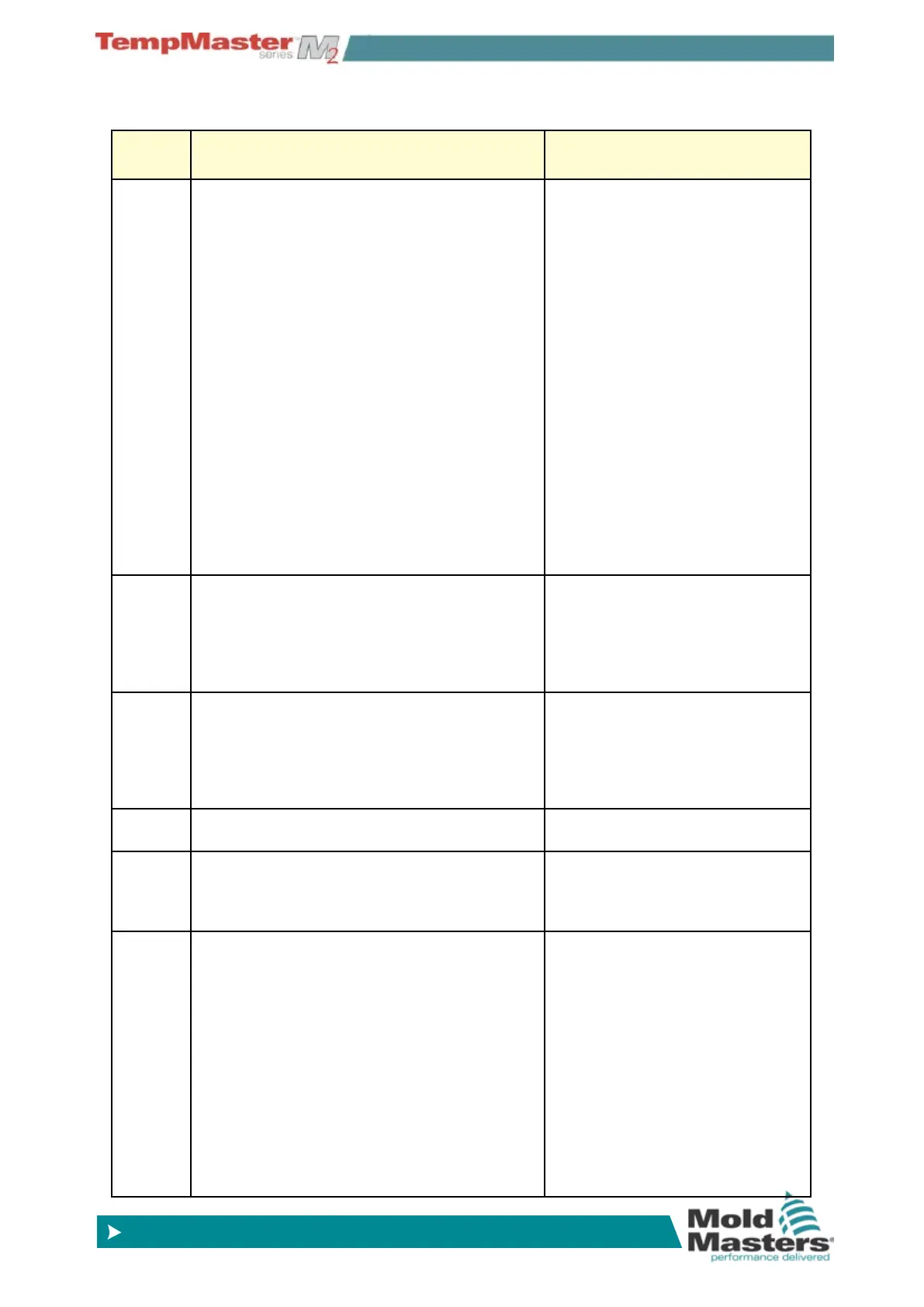

TROUBLESHOOTING

© 2014 Mold-Masters (2007) Limited. All Rights Reserved.

Revised 1 Oct, 2014

8-3

Fault and warning messages - contd.

Error

Message

Cause Action

N/Z All the control cards are interrogated in se-

quence, on a working controller you can see the

SCAN LEDs ashing in a sequence as each card

is briey checked for satisfactory communication.

If any card fails to respond to the console then an

N/Z error message is displayed for the offending

zone.

If every zone shows N/Z and no

cards show or ash their SCAN

LEDs then check the communication

lead between the console and the

controller cabinet.

If only one or two zones are dis-

playing N/Z then check the card for

faults. If you have recently changed

any cards and put any older dis-

crete-component cards into a new

controller that has surface-mount

cards then it is possible that the con-

sole’s modern scan speed is too fast

for the older control cards. In such

a condition, check the console baud

rate and try setting it to Low.

If this cures the problem and you

later replace the older card for a

newer surface mount version then

remember to reset the Baud rate

back to high for optimum working.

NONE The console has detected a control card that has

no settings.

This Error message may be seen

eetingly during switch on, it should

disappear after the initial card scan.

If the message persists then you

may need to re-apply the correct

card settings on the Setup page.

REV The card has detected an abnormal input at the

T/C termination that indicates a shorted or Re-

versed thermocouple.

If the REV alarm persists then you

should switch off the controller and

investigate the offending zone.

Alternatively you could slave the

offending zone to a good zone until

you have time to clear the fault.

RTD The RTD monitor cannot see an input (RTD is

open circuit)

Check the RTD and its wiring for a

broken connection.

T/C An open circuit thermocouple has been detected

and no auto-response has been selected in the

T/C Open Error column of the Setup page.

For immediate recovery you can

either slave that control zone to an

adjacent zone or change to open

loop control.

TRC If a triac fails it goes short circuit and passes full

load current.

In such a condition you have lost control of the

load and cannot switch it off from the console.

The TRC alarm ags up the fault state which

relies on operator intervention to manually shut

the system down.

Note: the triac monitor does not function in auto

mode. If the triac were to fail while the zone is run

in auto then the only indication will be an abnor-

mally high zone temperature because the triac

is passing high, uncontrolled current. The TRC

alarm is only seen if a triac fails on a zone that is

running in closed-loop manual condition.

If the triac has failed, return to your

supplier for repair.

Loading...

Loading...