Wiring a Signaling Line Circuit (SLC) Installation

AFP-200 PN 15511:H2 10/14/2002 49

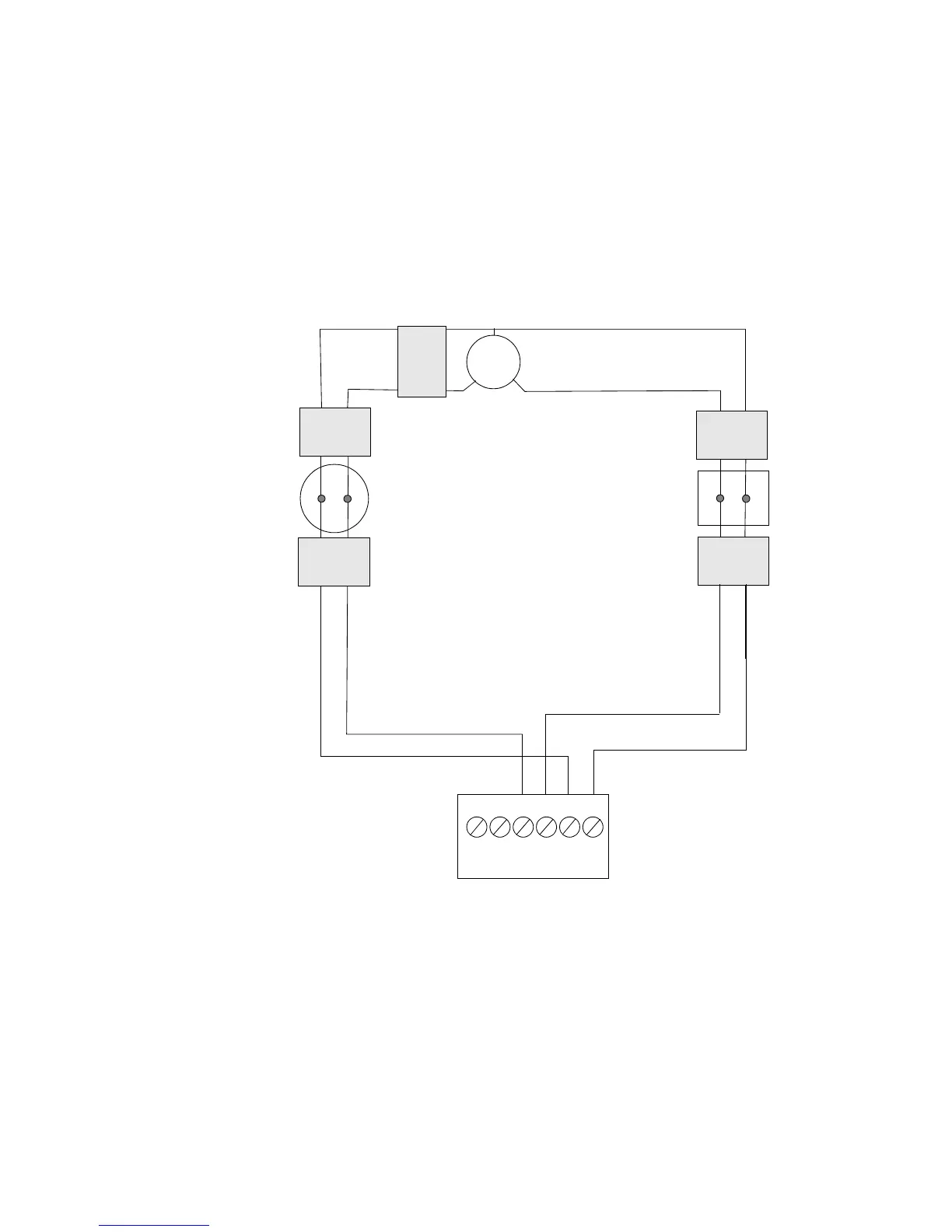

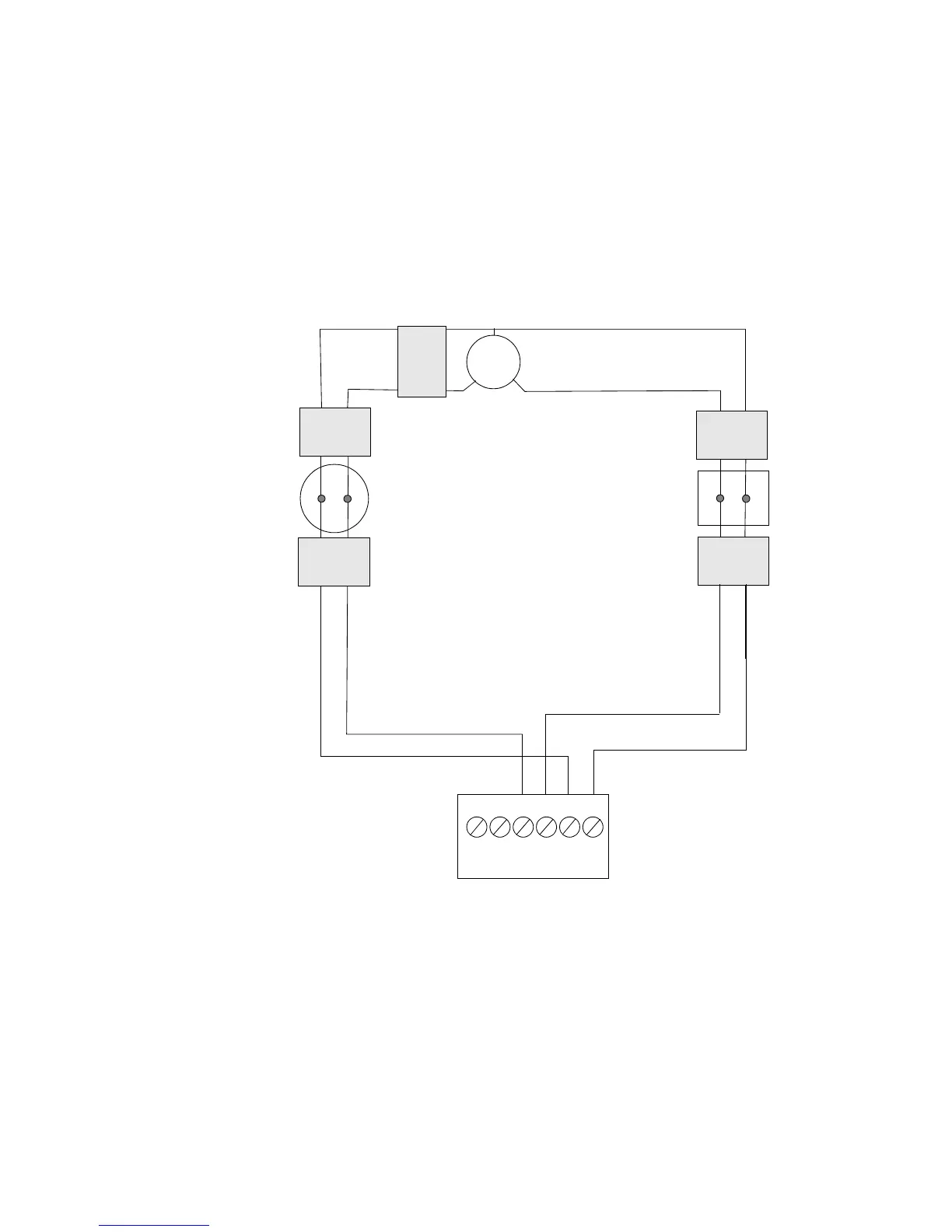

Style 7 Wiring Overview

Figure 29 shows typical wiring of a four-wire SLC that meet NFPA Style 7

requirements. As shown in Figure 29, flanking each SLC device with a pair of ISO-X

isolator modules protects each device from short circuit faults that may occur on other

SLC devices. For example, a fault on zone 2 will not affect zones 1 and 3. ISO-X

modules on either side of zone 2 will open the SLC. Zone 1 will still operate from

power on loop out and zone 3 will operate from SLC return. Because the control panel

cannot communicate with zone 2, a trouble signal(s) will be generated for that device.

Note: Do not T-Tap or branch a Style 7 four-wire SLC. Ratings and characteristics are

identical to a NFPA Style 6 four-wire SLC.

Figure 29 Four-wire SLC (Style 7)

2.9.9 Wiring an Isolator Module (ISO-X)

ISO-X Module Overview

You can connect a maximum of 25 devices between isolator modules. During a fault

condition, the control panel registers a trouble condition for each addressable device

which is isolated on the SLC segment or branch.

Refer to 2.9.6 “Setting an SLC Address for a Module” for instructions on addressing

the modules.

Addressable Manual

Pull Station (flanked by

ISO-X modules)

Note: All wiring between

a manual pull station

and ISO-X modules

should be enclosed in

conduit.

Note: If a non ISO base

is used, install ISO-X

modules on both sides

of devices within 20 feet

(6.096 m) in rigid

conduit.

Note: Locate ISO-X

module near detector.

Enclose wiring between

detector and ISO-X in

conduit.

CPU

Connect SLC Out to

TB 6-3 (+) and TB 6-5 (–).

Connect SLC Return to

TB 6-4 (+) and TB 6-6 (–).

SLC Out

SLC Return

Addressable

Detector

(Zone 1)

Two-wire Isolator

Detector Base

(Zone 2)

Addressable

Pull Station

(Zone 3)

Control Panel

ISO-X

ISO-X

ISO-X

ISO-X

ISO-X

_

+

_

+

1

2

3

4

5

6

A+BB+ B-A-A

1

2

34

1

2

34

1

2

3

4

1

2

3

4

1

2

3

1

2

3

4

Technical Manuals Online! - http://www.tech-man.com

Loading...

Loading...