System Manual Oxford Instruments Plasma Technology OpAL

3.13 Precursor

NOTE: Different precursors can be used to deposit the same film. Where possible,

OIPT will endeavour to use novel precursors or find alternatives which are

safer to handle, use and manage in our systems.

Unless benefits are significant, OIPT is not recommending solid precursors.

A careful selection and evaluation of precursors is performed prior to the

order intake process

A precursor is a term for a source chemical which may be in a solid, liquid or gas state.

The precursors may be generally categorized as;

Gases: N2, O2, O3 (in-situ), NH3, WF6, H2, …

High Vapour Pressure (HVP): e.g. 5 –40 Torr at room temperature liquids (e.g. TMA, SiCl4,

TiCl4, H2O) and solids (e.g. W(CO)6)

Low Vapour Pressure (LVP): e.g. < 0.5Torr @ RT (eg. Some metal organic Zr, Ta and Hf

precursors) and solids (e.g. TaCl5, HfCl4, ZrCl4). (Some solids may be dissolved in a

solvent and handled as liquids)

There is an additional category which is for precursors with vapour pressures between 0.5

Torr and 5 Torr. In this case, the source pot is heated to at least 20-50 deg C above

ambient to increase the vapour pressure so that there is sufficient vapour to saturate the

wafer. The delivery method will very much depend on the precursor type, both vapour

draw and bubbling may be used

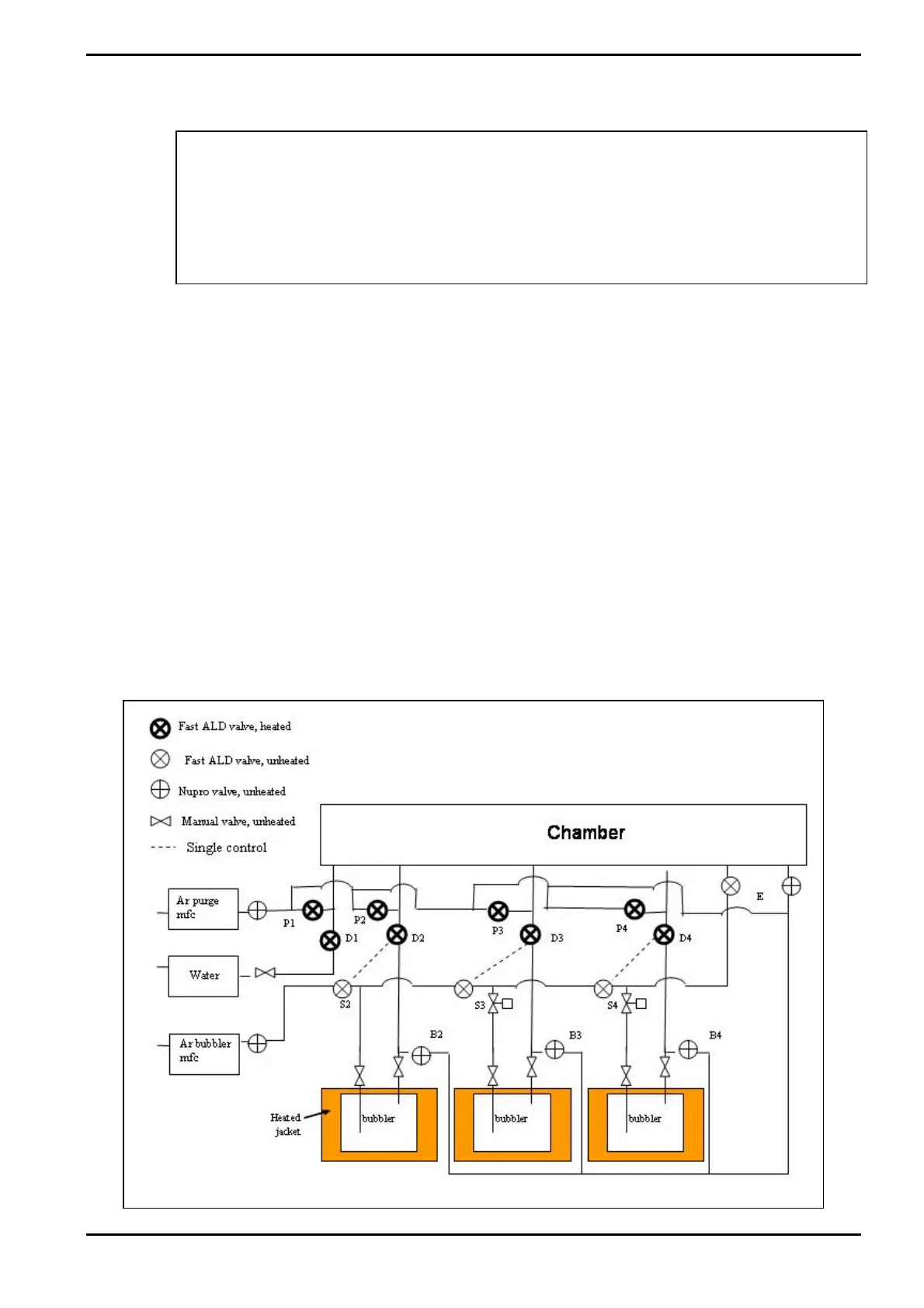

The precursors are transported in vapour from source container to the chamber. In

principle, two delivery methods, bubbling and vapour draw are used to deliver precursors.

Description

Printed: 07 August 2009 07:42 Page 3-41 of 46 Issue 1: August 07

Loading...

Loading...