Section 18: BODY

PA1562

69

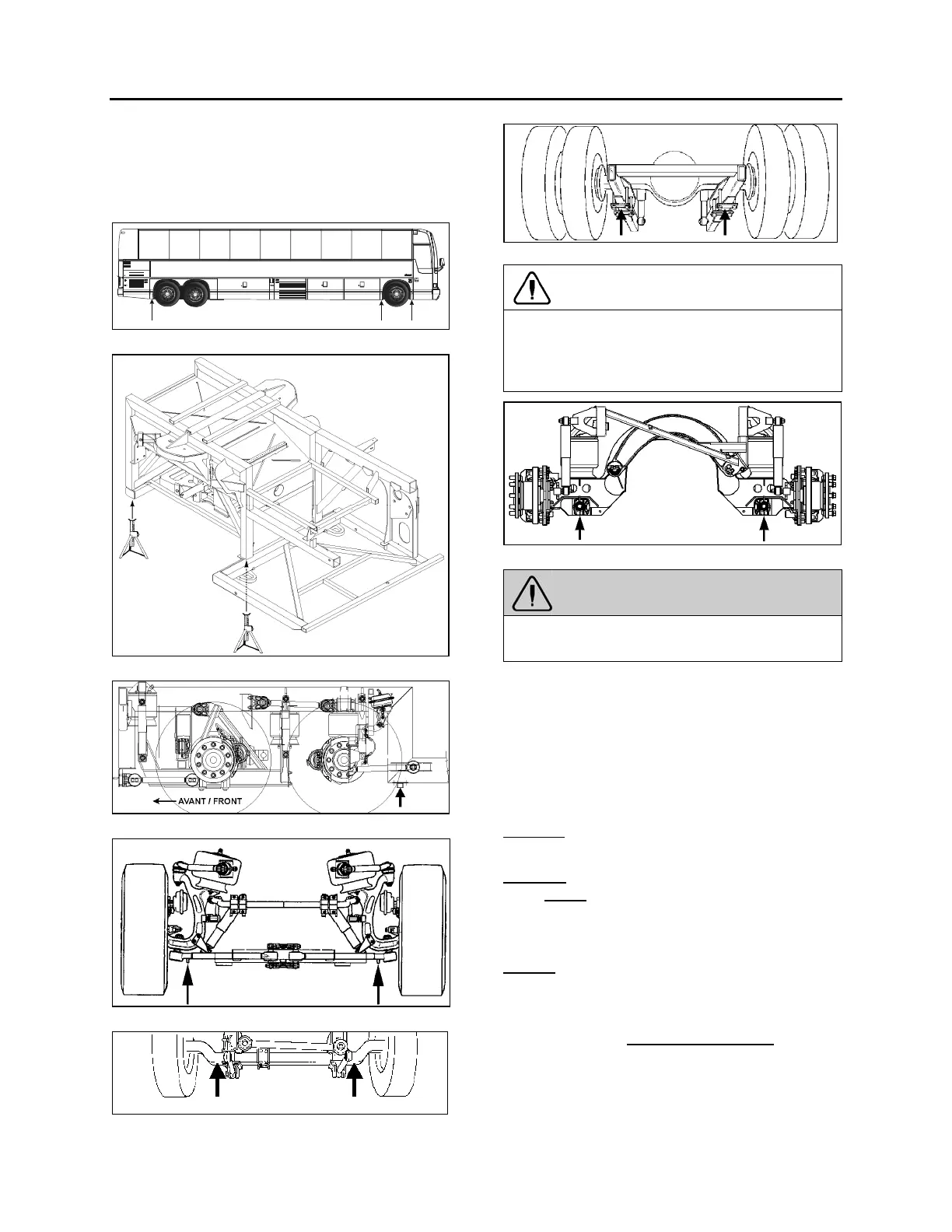

Twelve jacking points are located on the vehicle:

three are located on each side of the frame and

two are located under each axle. Refer to the

following illustrations for the location of jacking

points.

FIGURE 47: JACKING POINTS ON FRAME 18618

FIGURE 48: FRONT END JACKING POINTS 18592

FIGURE 49: REAR END JACKING POINTS 16166

FIGURE 50: JACKING POINTS ON IND. SUSPENSION 16139

FIGURE 51: JACKING POINT ON FRONT AXLE 10005

FIGURE 52: JACKING POINTS ON DRIVE AXLE 11005

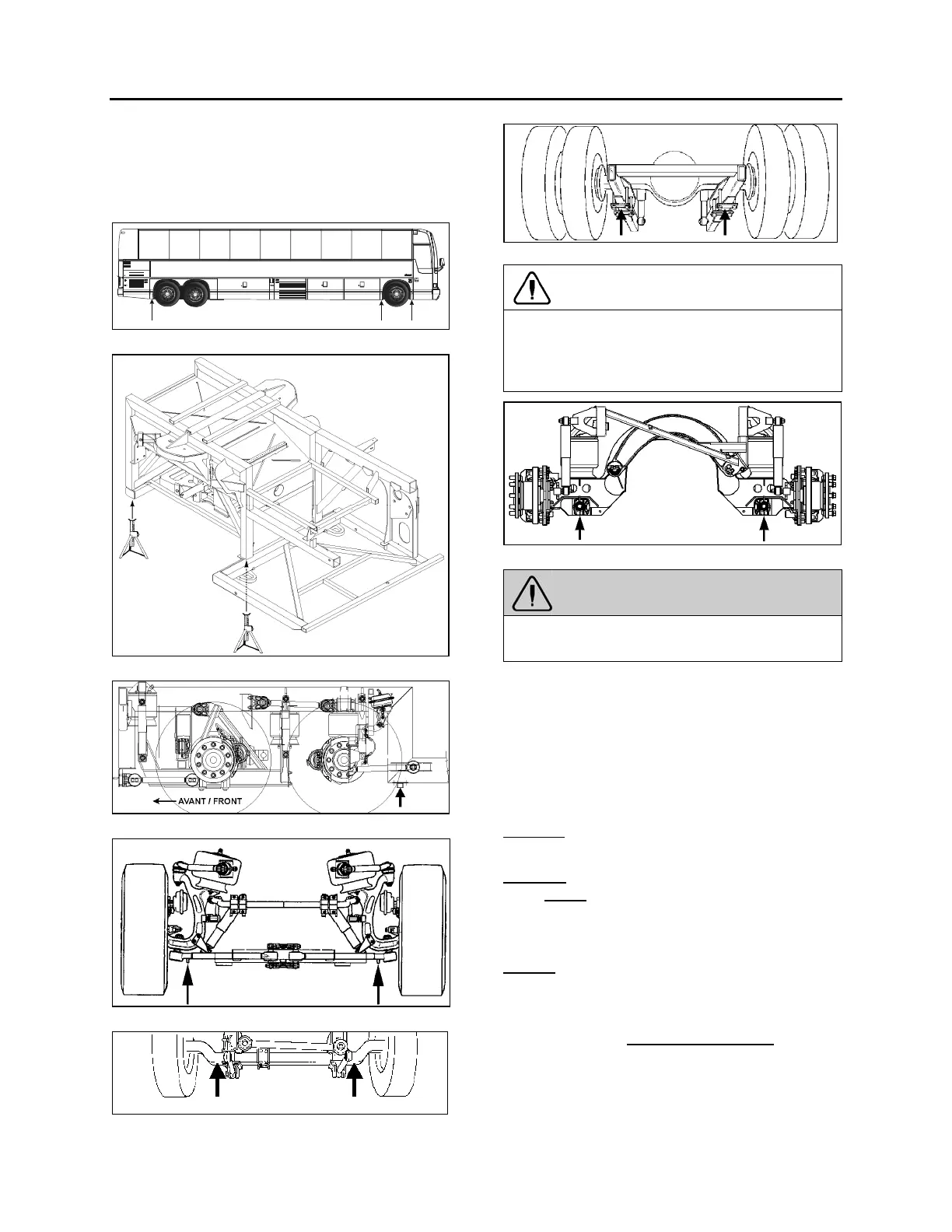

CAUTION

Always unload or retract the tag axle before

jacking the vehicle from the front and drive

axle jacking points to prevent damage to

suspension components.

FIGURE 53: JACKING POINTS ON TAG AXLE 11029

WARNING

The jacking points on the tag axle must be

used for raising the tag axle only.

Several kinds of hydraulic jacks can be used.

Only jack at the specified jacking points. Jack

must support the following capacities:

Front end: 20,000 lb. (9 100 kg);

Drive axle: 40,000 lb. (18 200 kg).

17.1 HYDRAULIC JACK

To raise

: turn release valve clockwise. Insert

handle in socket and raise by pumping.

To lower

: remove handle and turn the release

valve slowly

counterclockwise.

Always keep ram and extension screw retracted

when jack is not in use.

Service

: Check oil level when jack fails to raise

to full height. Lower ram completely with release

valve open and jack in upright position, remove

filler plug and refill to level of filler hole with

hydraulic jack oil. Never use brake fluid

.

Loading...

Loading...