Page No.11

Manual No. NDS8

Spicer Speciality Axle Division - Technical Publications

© Spicer Speciality Axle Division

OVERHAUL PROCEDURES

HUB END REASSEMBLY CONTINUED

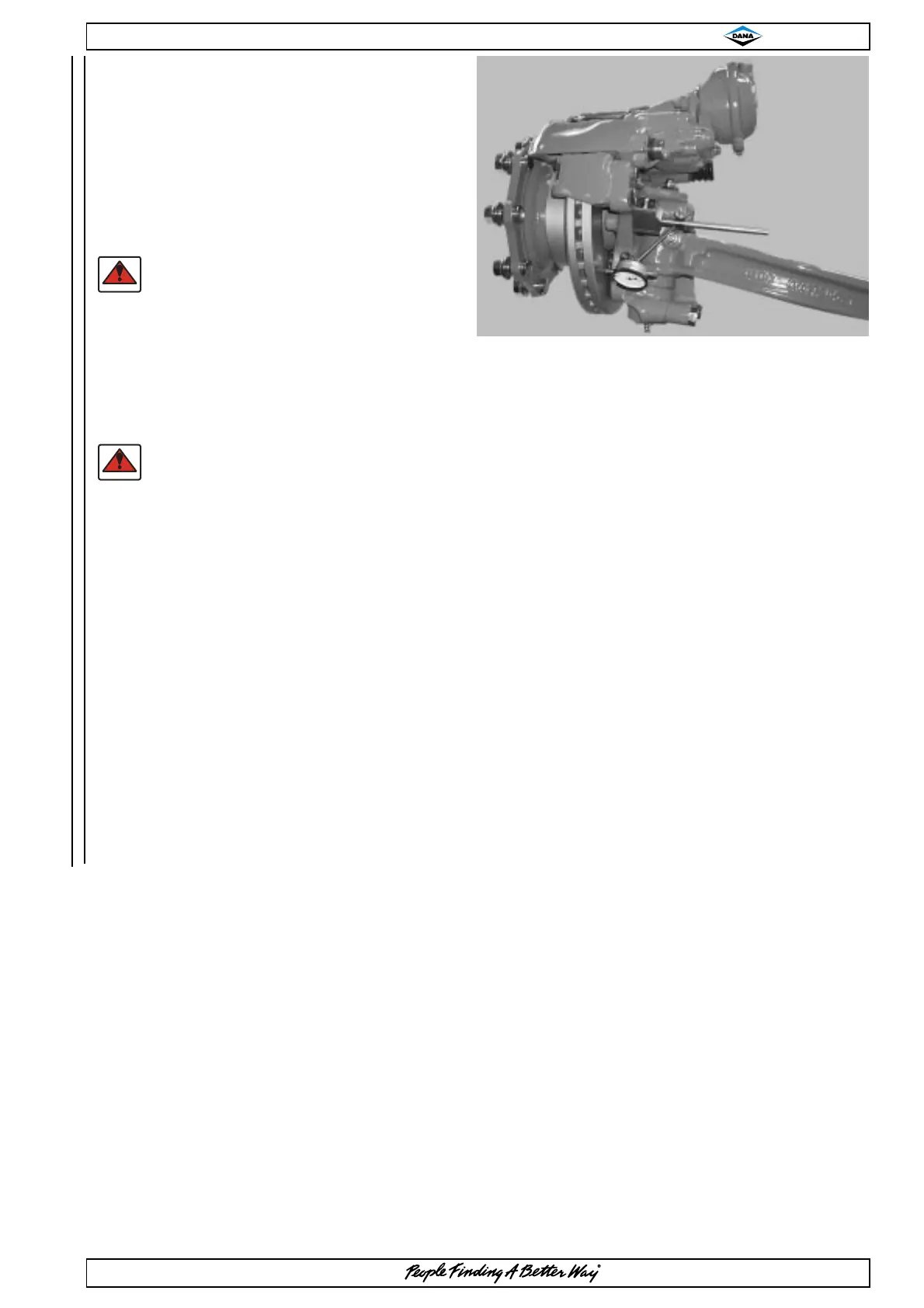

15. Once the hub flange has been correctly

fitted; it is necessary to check the

axial run out of the brake disc.

16. Position a metric dial test indicator onto

axle in a suitable position as shown.

NOTE:-

POSITION MAY VARY DEPENDENT ON

AXLE SPECIFICATION

17. Position stylus of dial test indicator onto

brake disc as shown.

18. Rotate the hub through 360° and note any

movement of the dial test indicator.

NOTE:-

MAXIMUM AXIAL RUNOUT IS 0.1mm

19. Should axial runout exceed 0.1mm. the

brake disc is out of specification .

20. Remove and check out of specification

disc to ensure no damage has occured to

the mounting faces, or that no dirt is

present.

21. Remove any dirt found on the mounting

faces and refit and re check disc.

NOTE:-

DAMAGED DISCS SHOULD BE

REPLACED AS A MATTER OF

COURSE!

22. Should it be found that a cleaned and

refitted disc is still out of specification; it

must be replaced.

Loading...

Loading...