Page No.15

Manual No. NDS8

Spicer Speciality Axle Division - Technical Publications

© Spicer Speciality Axle Division

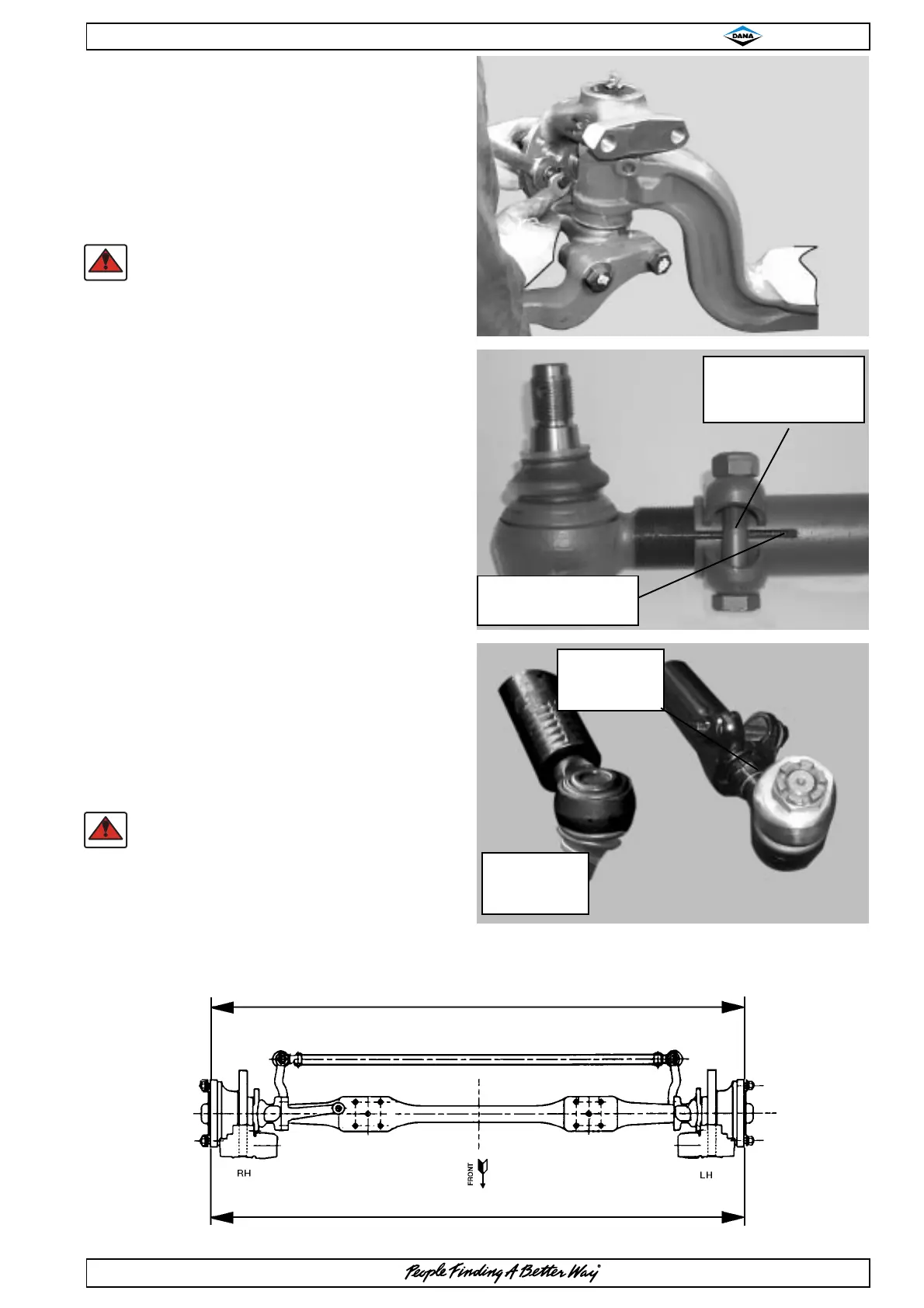

Clamp bolt

type A

Socket assembly

OVERHAUL PROCEDURES

HUB END REASSEMBLY CONTINUED

34. Refit lockstop screws and adjusting nuts

35. Reset lockstop screws to achieve correct

lock angles as shown on installation drawing

or vehicle manufacturers specifications.

NOTE:-

DO NOT ALLOW LOCKSTOP THREADS

TO PROTRUDE THROUGH FRONT FACE

OF SWIVEL.

36. Check wheel alignment as follows :-

a) Set axle in straight ahead position.

b) At a point level with wheel centre,

measure distance over hubs / wheel

rims, both in front and behind axle

centre.

c) Front measurement ‘B’ should be

0.0" to 0.04" (0.0 to 1mm) LESS

than rear measurement ‘A’.

d) Any adjustment on type A

socket and tie rod assemblies can

be effected by slackening clamp

bolts in ball sockets and rotating

track rod tube.

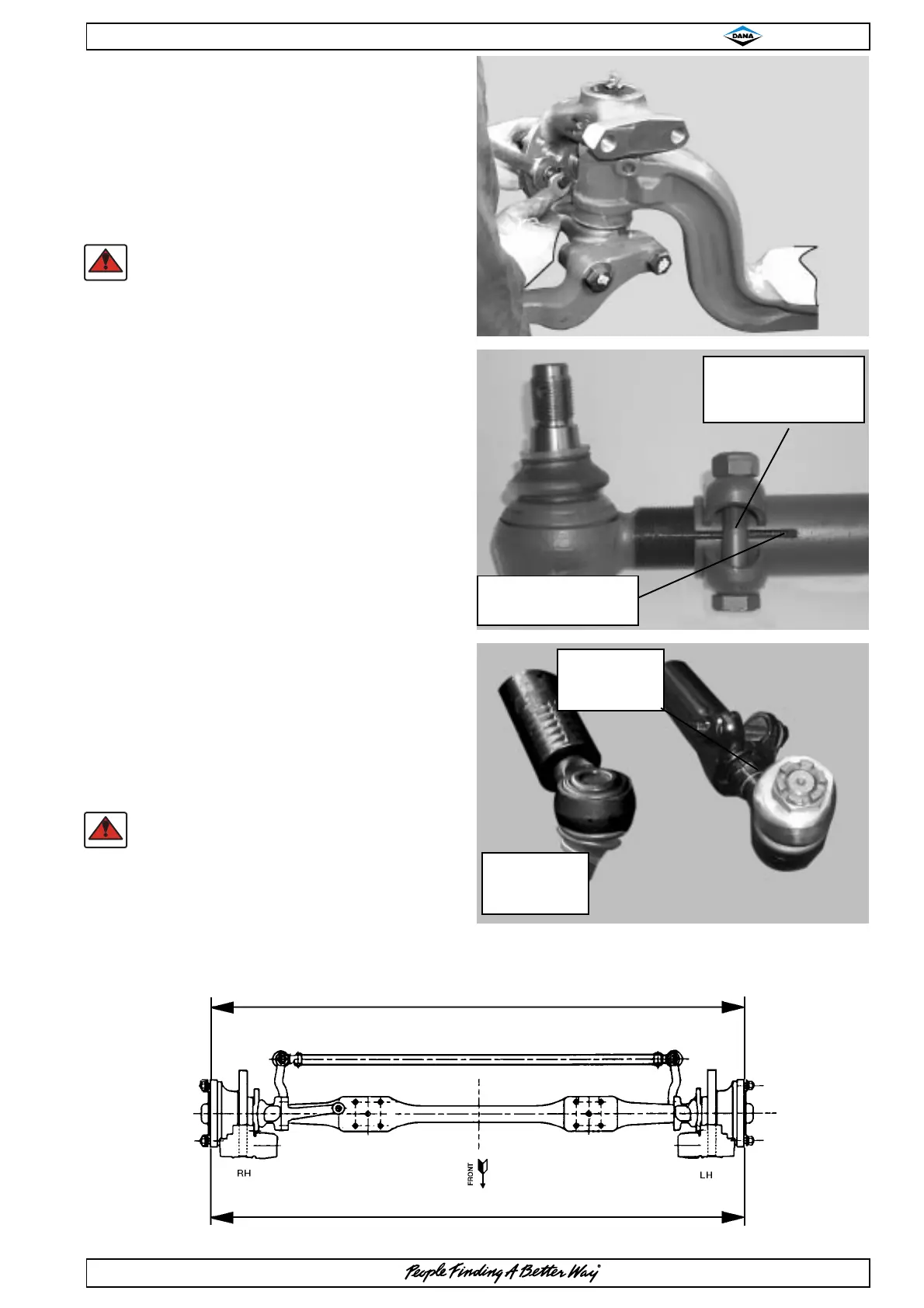

For type B socket and tie rod

assemblies, slacken the clamped

end of the assembly and use the

adjuster ring.

e) After adjustment, tighten clamp bolts

to specified torque.

NOTE:-

WHEN ADJUSTING TYPE A TIE RODS,

ENSURE SOCKET THREADS ARE

EQUALLY POSITIONED IN EACH END OF

THE TIE ROD AND THAT THE END OF

THE SOCKET THREAD IS NOT VISIBLE

THROUGH THE SAWCUT

'B'

'A'

Adjuster ring

type B Socket

assembly

End of threads must

not be visible here

Crimped end

type B Socket

assembly

Loading...

Loading...