12

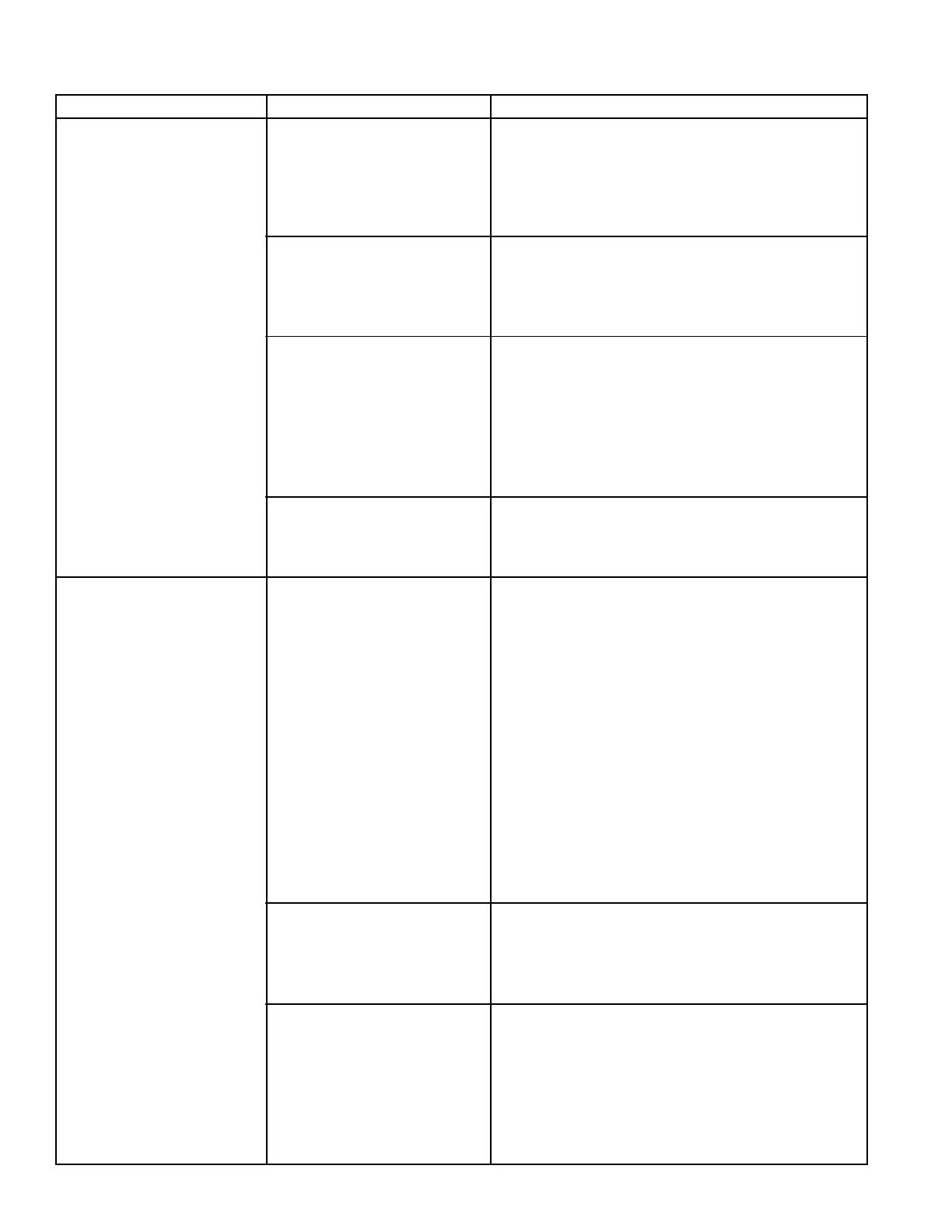

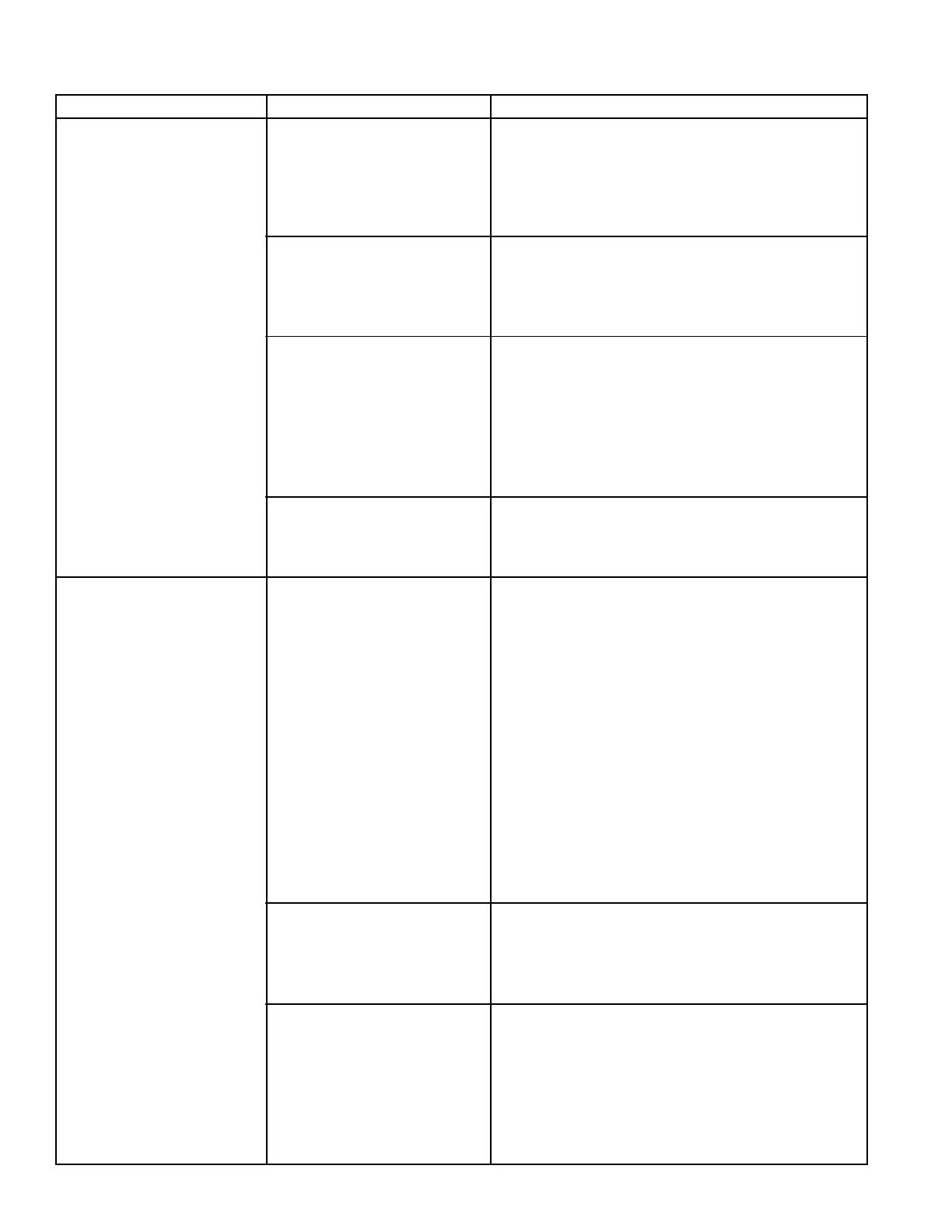

COMPRESSOR TROUBLESHOOTING CHART (Continued)

SYMPTOMS CAUSE

REMEDY

1. (Continued.) F. Compressor runs loaded F. Vehicle system leakage should not exceed indus-

an excessive amount of try standards of 1 psi pressure drop per minute

time. without brakes applied and 3 psi pressure drop

per minute with brakes applied. If leakage is

excessive, check for system leaks and repair.

G. Excessive engine G. Test for excessive engine crankcase pressure &

crankcase pressure. replace or repair ventilation components as

necessary. (An indication of crankcase pressure

is a loose or partially lifted dipstick.)

H. Excessive engine oil H. Check the engine oil pressure with a test gauge

pressure. and compare the reading to the engine specifica-

tions. Bendix does not recommend restricting the

compressor oil supply line because of the

possibility of plugging the restriction with oil

contaminants. Minimum oil supply line size is

3/16" I.D. tubing.

I. Faulty compressor. I. Replace or repair the compressor only after

making certain none of the preceding installation

defects exist.

2. Noisy compressor A. Loose drive gear or A..Inspect the fit of the drive gear on the compres-

operation. components. sor crankshaft. The gear or coupling must be

completely seated and the crankshaft nut must

be tight. If the compressor crankshaft surface is

damaged, it is an indication of loose drive

components. If damage to the compressor

crankshaft is detected, replace the compressor.

When installing the drive gear or pulley, torque

the crankshaft nut to the appropriate torque

specifications and use care when pressing drive

components onto the crankshaft.

Do not back off the crankshaft nut once it is

tightened to the proper torque.

Do not use impact wrenches to install the

crankshaft nut.

B. Excessively worn drive B. Inspect drive gear and couplings and engine for

couplings or gears. excessive wear. Replace as necessary.

(Nonmetallic gears should be replaced when the

compressor is changed.)

C. Compressor cylinder head C. Inspect the compressor discharge port and

or discharge line discharge line for carbon build-up. If carbon is

restrictions. detected, check for proper cooling to the

compressor. (See Cause and Remedy (D) under

Symptom #1.) Inspect the discharge line for kinks

and restrictions. Replace discharge line as

necessary.

Loading...

Loading...