13

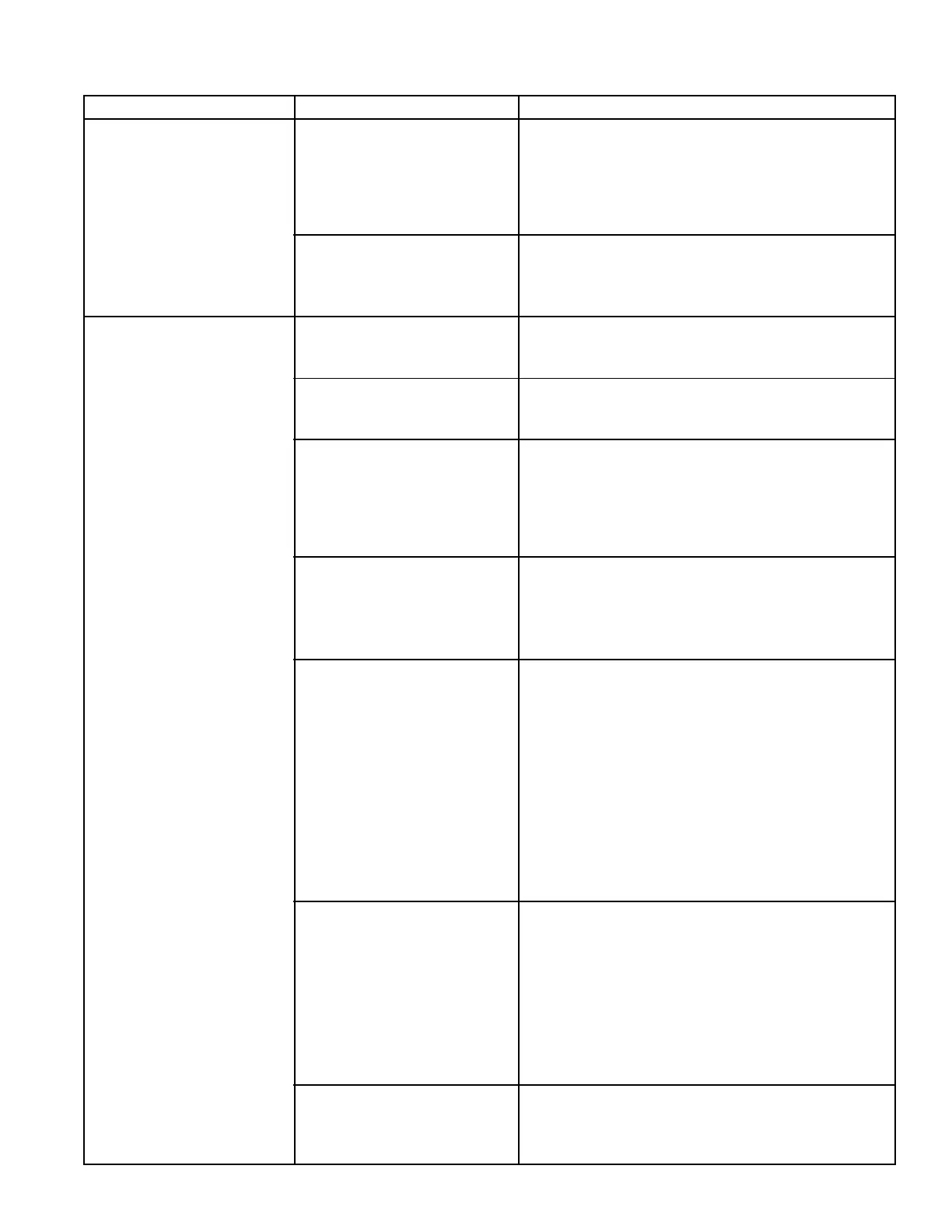

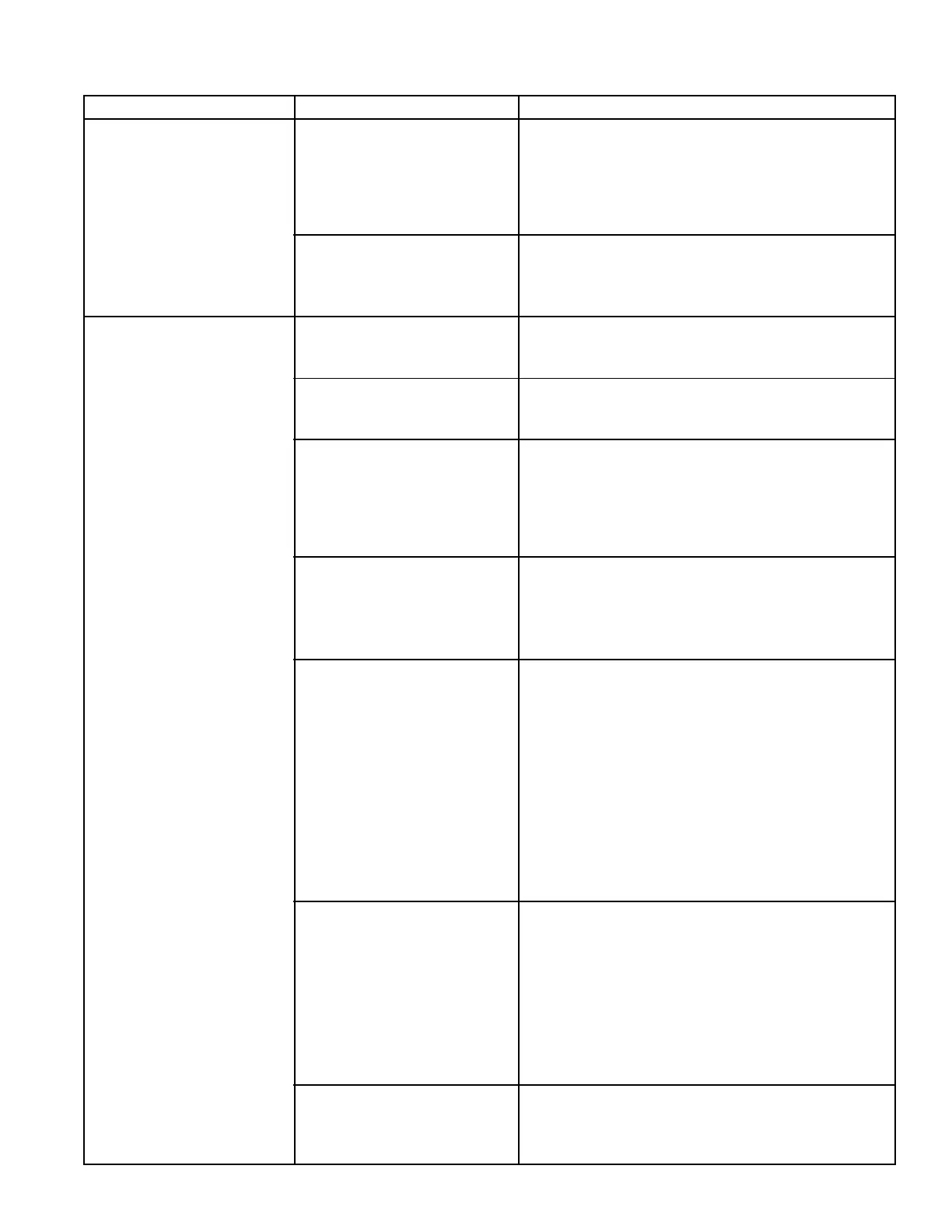

COMPRESSOR TROUBLESHOOTING CHART (Continued)

2. (Continued.) D. Worn or burned out D. Check for proper oil pressure in the compressor.

bearings. Minimum required oil pressure; 15 psi engine

idling, 15 psi maximum governed engine rpm.

Check for excessive oil temperature—should not

exceed 240 degrees Fahrenheit.

E. Faulty compressor. E. Replace or repair the compressor after

determining none of the preceding installation

defects exist.

3. Excessive build-up and A. Dirty induction air filter. A. Inspect engine or compressor air filter and

recover time. Compressor replace if necessary.

should be capable of

building air system from B. Restricted induction line. B. Inspect the compressor air induction line for kinks

85-100 psi in 40 seconds and restrictions and replace as necessary.

with engine at full

governed rpm. Minimum C. Restricted discharge line C. Inspect the compressor discharge port and line

compressor performance or compressor discharge for restrictions and carbon build-up. If a carbon

is certified to meet Federal cavity. build-up is found, check for proper compressor

requirements by the cooling. Replace faulty sections of the discharge

vehicle manufacturer. Do line.

not downsize the original

equipment compressor. D. Slipping drive components. D. Check for faulty drive gears and couplings and

replace as necessary. Check the condition of

drive belts and replace or tighten, whichever is

appropriate.

E. Excessive air system E. Test for excessive system leakage and repair as

leakage. necessary. Use the following as a guide: Build

system pressure to governor cutout and allow the

pressure to stabilize for one minute. Using the

dash gauge, note the system pressure and the

pressure drop after two minutes.

The pressure drops should not exceed:

1. 2 psi in each reservoir for a single vehicle.

2. 6 psi in each reservoir for a tractor and trailer.

3. 8 psi in each reservoir for a tractor and 2

trailers.

F. Sticking unloader pistons. F. Check the operation of the unloading mechanism.

Check for proper operation of the compressor air

governor. Make certain the air connections

between the governor and compressor are

correct. Refer to figure 3. If the governor is

operating properly, replace the unloader

mechanism. Inspect for bent, linked or blocked

tubing leading to or from the governor.

G. Faulty compressor. G. Replace or repair the compressor after

determining none of the preceding installation

defects exist.

SYMPTOMS CAUSE

REMEDY

Loading...

Loading...