Section 16: SUSPENSION

PA1562

7

are eye-type mountings. The front axle is

provided with two shock absorbers (Fig. 1, 2,

and 4).

Shock absorbers are non-adjustable and non-

repairable. Maintenance requirements involve

replacement of the rubber mounting bushings,

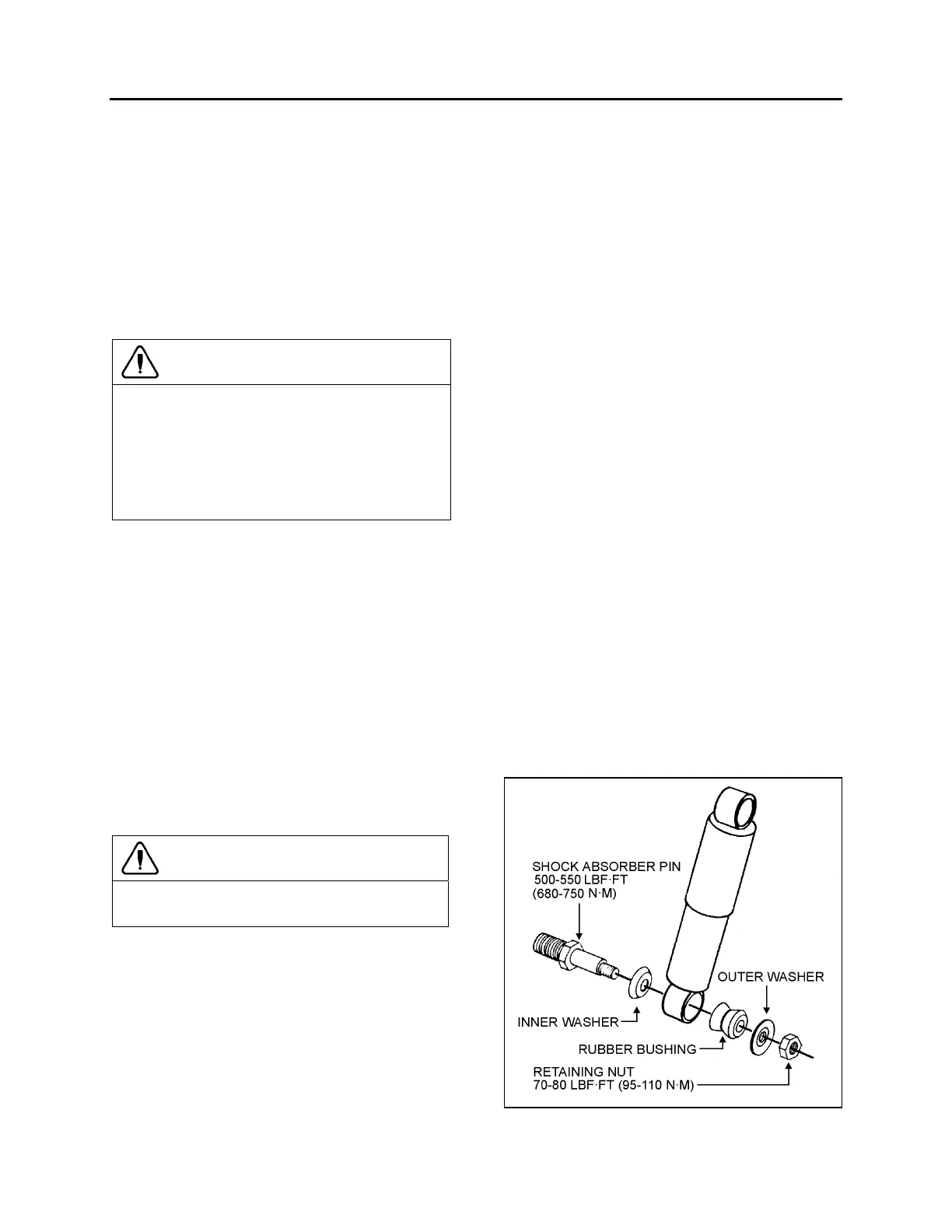

and tightening of all shock absorber pins at the

proper torque of 500 - 550 lbf-ft (680 - 750 Nm)

when shock absorber replacement occurs. If a

shock absorber becomes inoperative, complete

unit must be replaced.

CAUTION

When a shock absorber is found defective,

always replace with a new set on affected

axle, except if there has been a recent

replacement of one unit. The following method

will help in determining if both shock

absorbers on the same axle have to be

replaced.

2.2.1 Inspection

Loosen lower mounting of both shocks, and then

carefully attempt to raise and lower the bottom

portion of each shock. Note the rate of effort for

distance of travel. Replace both shocks if a

definite differential rate is found.

The shock must be bench checked in an upright,

vertical position. If checked in any other position,

air will enter the cylinder tube and make the

shock absorber appear defective.

Proceed as follows to check shock absorbers:

1. With the shock absorber in a vertical

position (top end up), clamp the bottom

mount in a vise.

CAUTION

Do not clamp the reservoir tube or the dust

tube.

2. Rotate the dust tube. Notice any binding

condition (may be compared with new unit).

Binding condition indicates a scored rod.

Units with scored rods should be replaced.

3. Fully extend shocks and check for leaks in

the seal cover area. Shock fluid is a very

thin hydraulic fluid that has a characteristic

odor and dark brown tint. A slight trace of

shock fluid around the seal cover area is not

a cause for replacement. The shock seal is

designed to permit a very slight seepage to

lubricate the rod. Units that leak should be

replaced.

4. Visually check shock for dents that could

cause the shock to bind. Also, check for a

bent rod.

5. Extend and collapse shock several times to

determine that it has control (resistance) in

both rebound and compression.

6. Visually inspect the shock mountings and

vehicle mounting for:

a. Broken mounts;

b. Extreme bushing wear;

c. Shifted bushing or sleeve;

d. Deep cracks in bushing material

(shallow surface cracks are normal);

e. Loose shock absorber pins;

f. Presence of convex washers, and their

position relative to the rubber bushing.

2.2.2 Removal

1. Remove nuts and washers from shock

absorbers on upper and lower mounting

pins, taking care to identify the inner and

outer washers to ease reinstallation. Refer

to figure 4 for details.

2. Remove the shock absorber assembly from

pins.

3. Remove the two inner bushings from the

shock absorber and discard them.

FIGURE 4: SHOCK ABSORBER 16008

Loading...

Loading...