Section 16: SUSPENSION

PA1562

20

3.13.3 Assembly

Execute assembly of the new joint parts in the

following sequence:

1. Complete moistening of the contact surface

between housing bore and ball pin through

application of the grease.

NOTE

Apply grease, only in the case of repair kit

(Prévost # 611114)).

2. Insert ball pin/bushing, assembly. In case of

the two-bolt type, ensure that the bolt bores

are in the correct position in relation to the

axis of the tube.

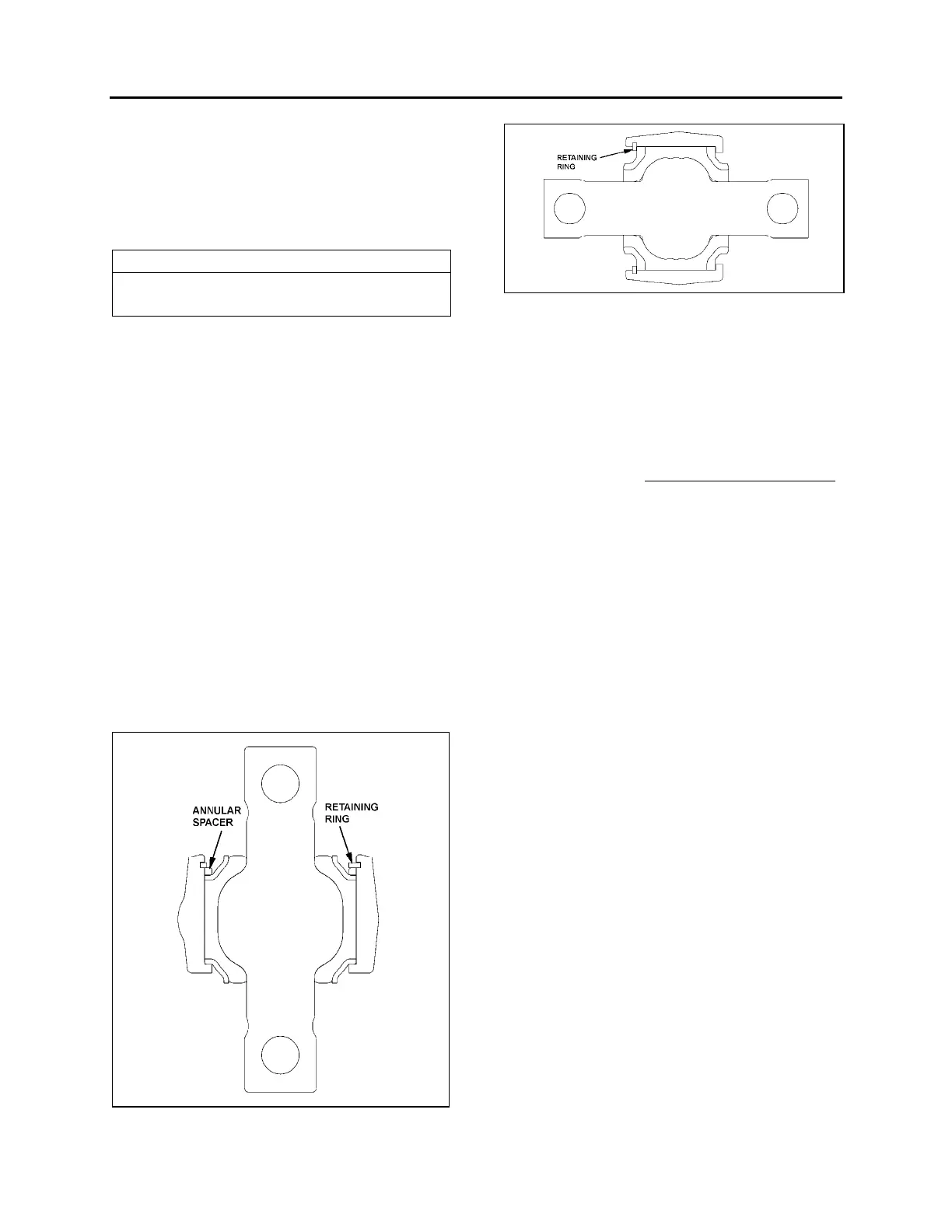

3. Place joint in receiving fixture and mount

annular assembly tool on the housing. Then

locate annular spacer and retaining ring in

the housing using axial load with the aid of

assembly matrix. If the ends of the annular

spacer are not in contact with each other,

the thus formed opening must be located at

180° to the opening of the retaining ring.

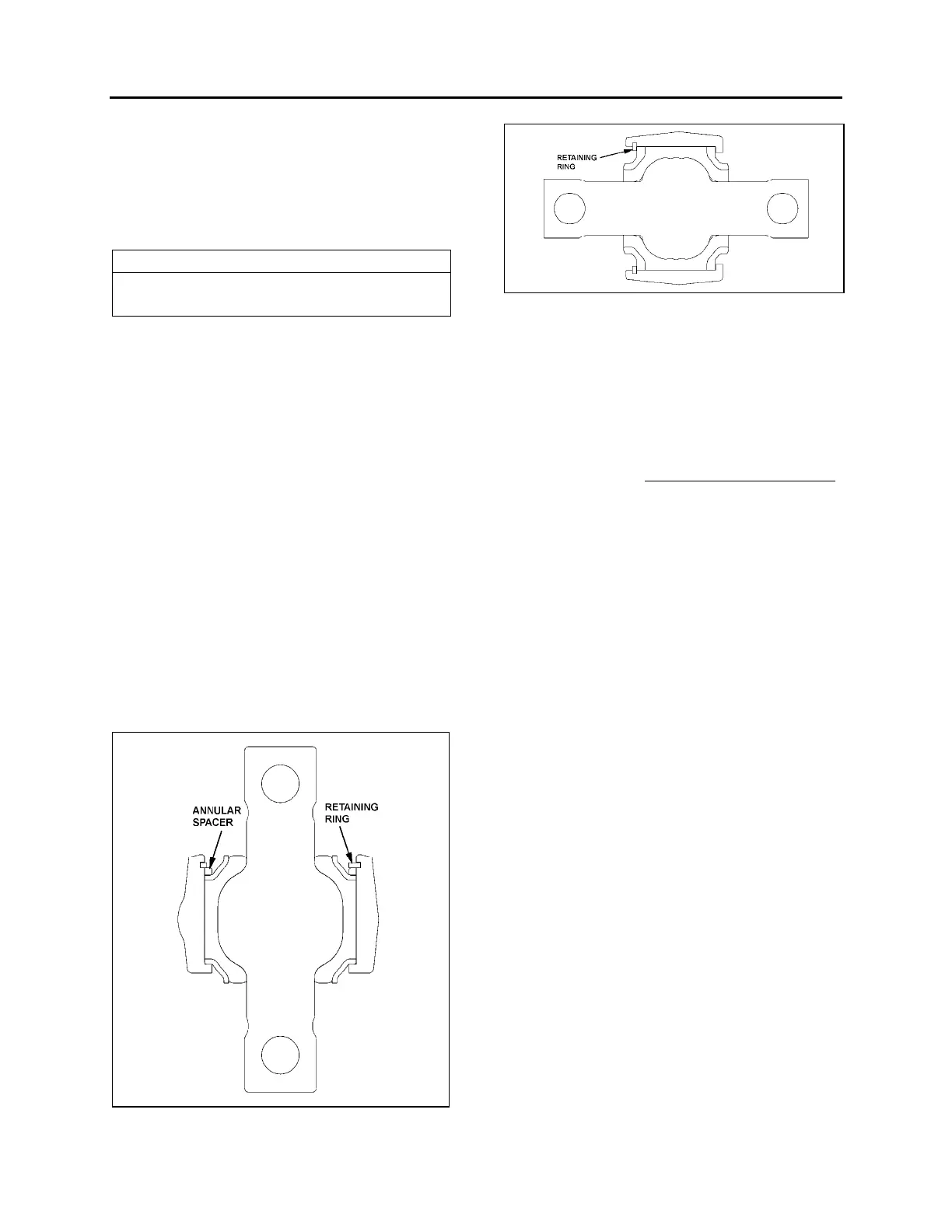

Pay attention during assembly to ensure

that the retaining ring eyelets are located at

each side of the housing shaft axis

(retaining ring eyelet lug points to tube), and

that retaining ring is properly engaged in the

groove of the housing.

4. When repairing defective ball pin

assemblies, the necked down-bolt must

regularly be replaced with a new one.

FIGURE 25: LOWER A-ARM BALL JOINTS 16114

FIGURE 26: UPPER A-ARM BALL JOINTS 16115

3.14 LOWER A- ARM CENTRAL BALL JOINT

3.14.1 Inspection

Take off the load from the ball joint by lifting the

front of the vehicle. Apply a load on the joint in

all of the degrees of freedom in an axial, radial,

etc. sense with a suitable lever tool. After the

load is taken off, the joint has to spring back into

its starting position. Free play is not acceptable

.

Separation of rubber from ball pin or external

joint bushing shell is in accordance with "normal

wear characteristics".

When the following characteristics are noted,

the joint is to be changed:

¾ Free play;

¾ Radial cracking of the external bushing

shell.

3.14.2 Stripping Down

Strip down the defective joint through removal of

retaining ring, annular spacer and ball

pin/bushing, assembly and thereafter clean out

housing bore and locking circlips groove.

3.14.3 Assembly

Assemble the new component parts of the joint

in the following sequence:

1. Complete moistening of the contact surface

between housing bore and ball pin through

application of the grease.

2. Place joint in receiving fixture and mount

annular assembly tool on the housing. Then

locate annular spacer and retaining ring in

the housing using axial load with the aid of

assembly matrix. If the ends of the annular

spacer are not in contact with each other,

the thus formed opening must be located at

180° to the opening of the retaining ring.

Pay attention during assembly to ensure

that the retaining ring eyelets are located at

each side of the housing shaft axis

(retaining ring eyelet lug points to tube), and

that retaining ring is properly engaged in the

groove of the housing.

Loading...

Loading...