Section 16: SUSPENSION

PA1562

21

3. Faultlessly apply grease by mechanical

means to bracket-outer core and ball-inner

cone. Insert bracket outer cone in fixture

with distance ring and then use press tool to

apply pressure to press mount with ball-

inner cone.

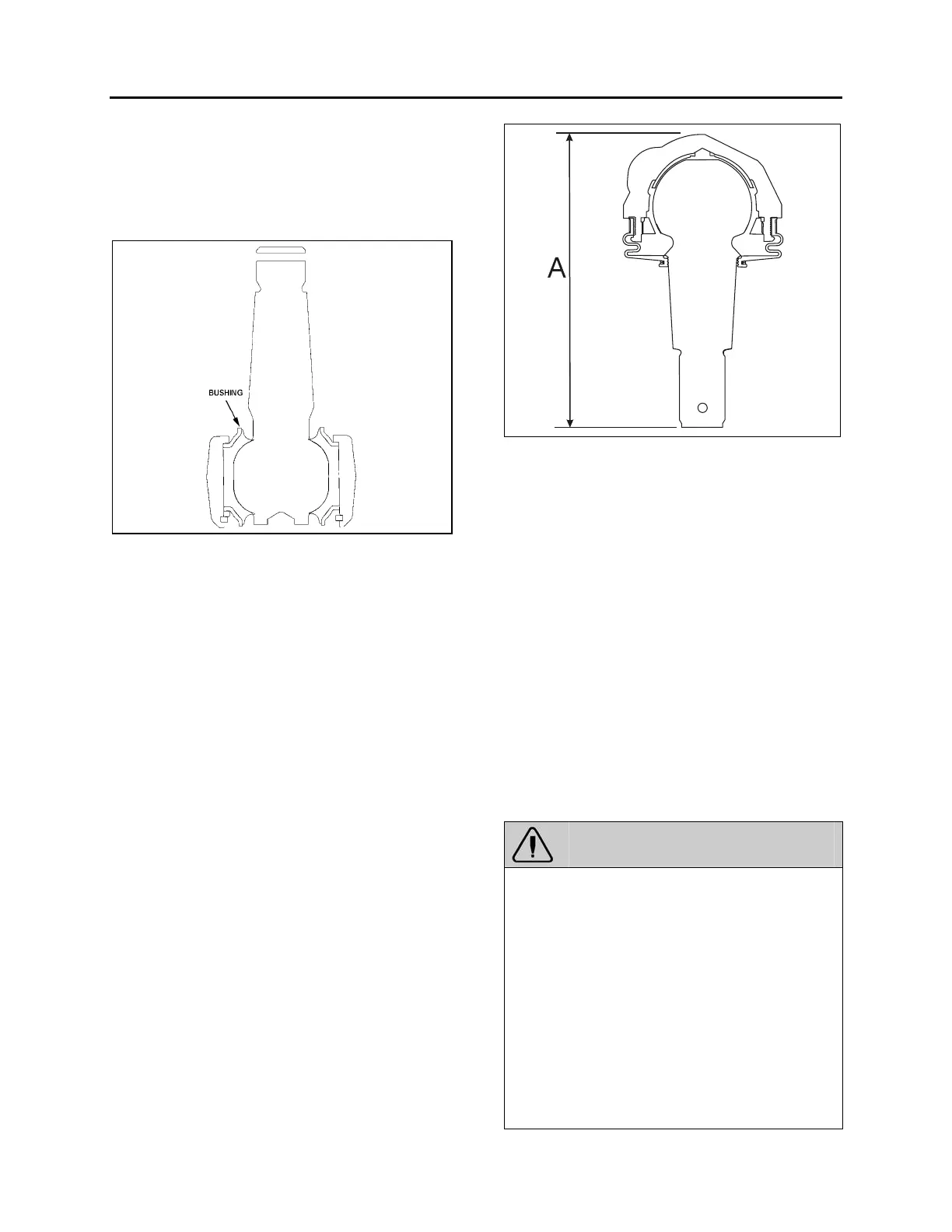

FIGURE 27: LOWER A-ARM CENTRAL BALL JOINT 16113

3.15 UPPER A-ARM CENTRAL BALL JOINT

3.15.1 Visual Inspection

Check the condition of the sealing boot, in

particular:

Check if the retainer ring, which secures the

sealing boot at the conical section of the ball

stud, is still present.

Check if grease is present on the external

surface of the sealing boots. Escaped fluid and

accumulations of grease on the sealing boot

may be the result of the sealing boot's rupturing.

In this case, the ball joint must be systematically

replaced.

3.15.2 Play Measurement

1. Raise the vehicle and support through axle

jacking points.

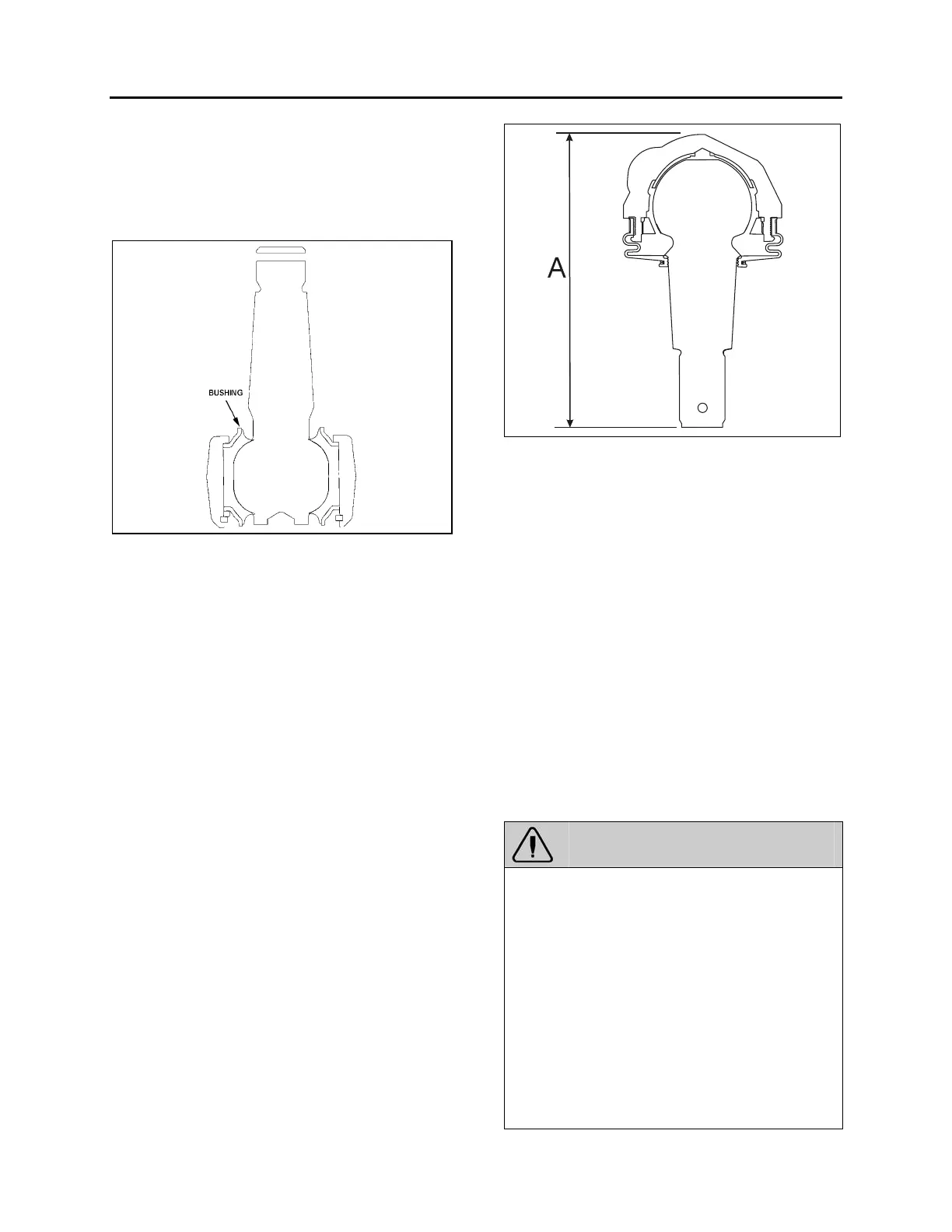

2. Using a caliper, measure dimension A on

figure 28.

3. With a lever tool, exert sufficient force under

the upper A-arm as to separate the upper A-

arm from the upright in order to have the ball

joint to its maximum extent. Remeasure

dimension A. If the difference between the

two dimensions is greater than 0.060"

(1.5 mm), then the ball joint should be

replaced.

FIGURE 28: UPPER A-ARM CENTRAL BALL JOINT 16116

3.16 FRONT END ALIGNMENT

Proper front end alignment must be maintained

to insure ease of steering and provide

satisfactory tire life. When making front end

alignment inspections, the vehicle must be level

and empty with the full weight of the vehicle on

the wheels.

Front end alignment inspections fall into two

groups: regular service inspections performed at

periodic intervals, and inspections to determine

the extent of damage after a collision or severe

service.

Regular service inspections concern toe-in,

camber and caster.

Any variation from the specified alignment will

indicate either a need for adjustment or a more

thorough inspection to determine if parts

replacement is required.

WARNING

During alignment, both camber and caster

among other angles are adjusted. When

adjusting these we install or remove shims

from the lower “A” arms of the ISS

suspension. After performing alignment, make

sure that the following is done:

¾ Installing a new lock nut after all shims are

finalized.

¾ Torque replaced nuts as per figure 32.

¾ Installing a longer bolt if less the 2 threads

are remaining after the nut.

¾ Using a Torque mark on the nut for future

visual inspection.

Loading...

Loading...