Section 16: SUSPENSION

PA1562

19

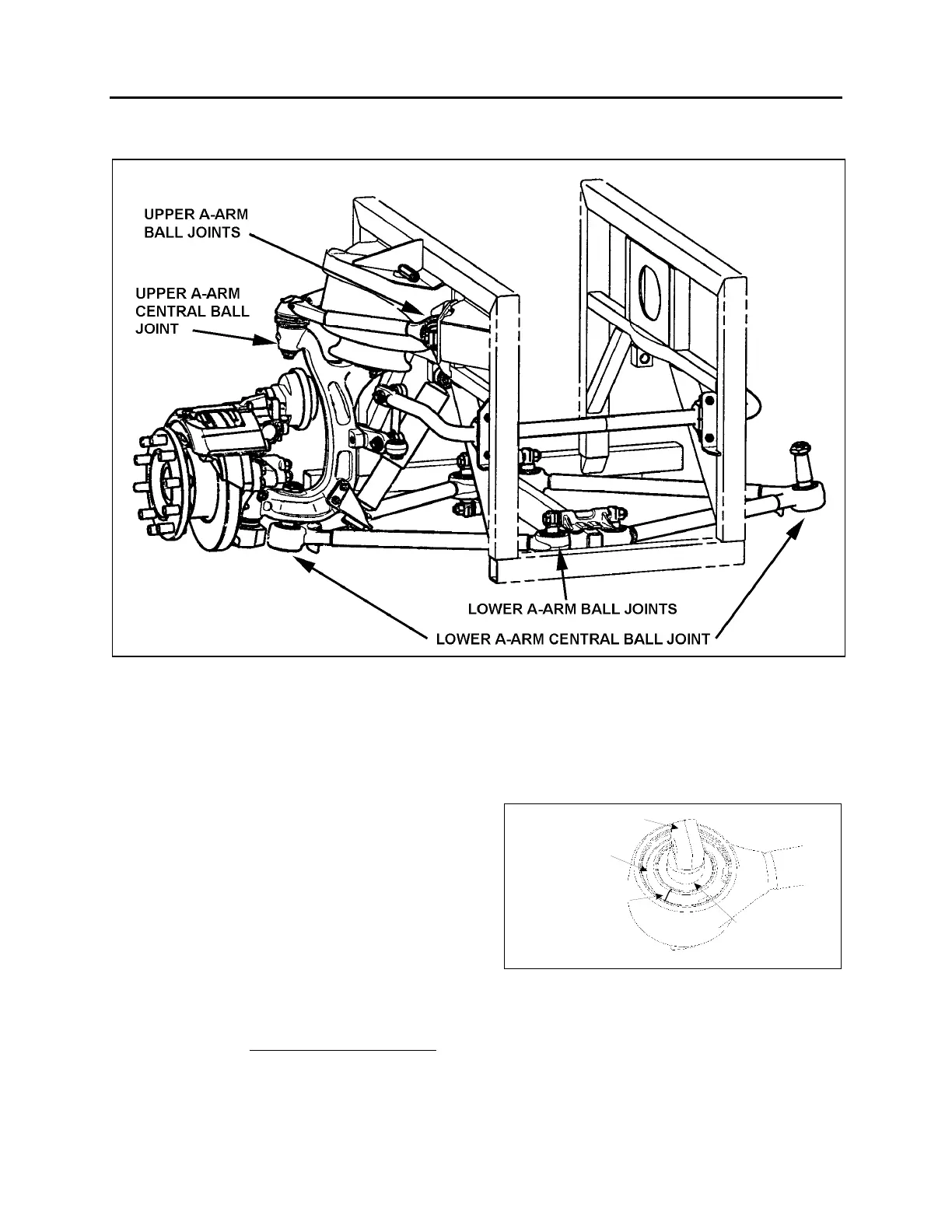

3.12 BALL JOINTS

FIGURE 23: BALL JOINTS LOCATION 16137

3.13 LOWER AND UPPER A-ARM BALL

JOINT

The assembly work may be done only by a

recognized specialized workshop. Ensure that

old and new parts do not get mixed up with each

other. It is for this reason that all the old parts

are to be scrapped immediately after a joint has

been stripped down. A complete repair set must

be used for each joint repaired, i.e. use of only

part of a repair set is not permissible.

3.13.1 Inspection

Take off the load from the ball joint by lifting the

front of the vehicle. Apply a load on the joint in

all of the degrees of freedom in an axial, radial,

etc. sense with a suitable lever tool. After the

load is taken off, the joint has to spring back into

its starting position. Free play is not acceptable

.

Separation of rubber from ball pin or external

joint shell is in accordance with "normal wear

characteristics".

When the following characteristics are noted,

the joint is to be changed:

¾ Free play;

¾ Radial cracking of the external sheet-metal

race.

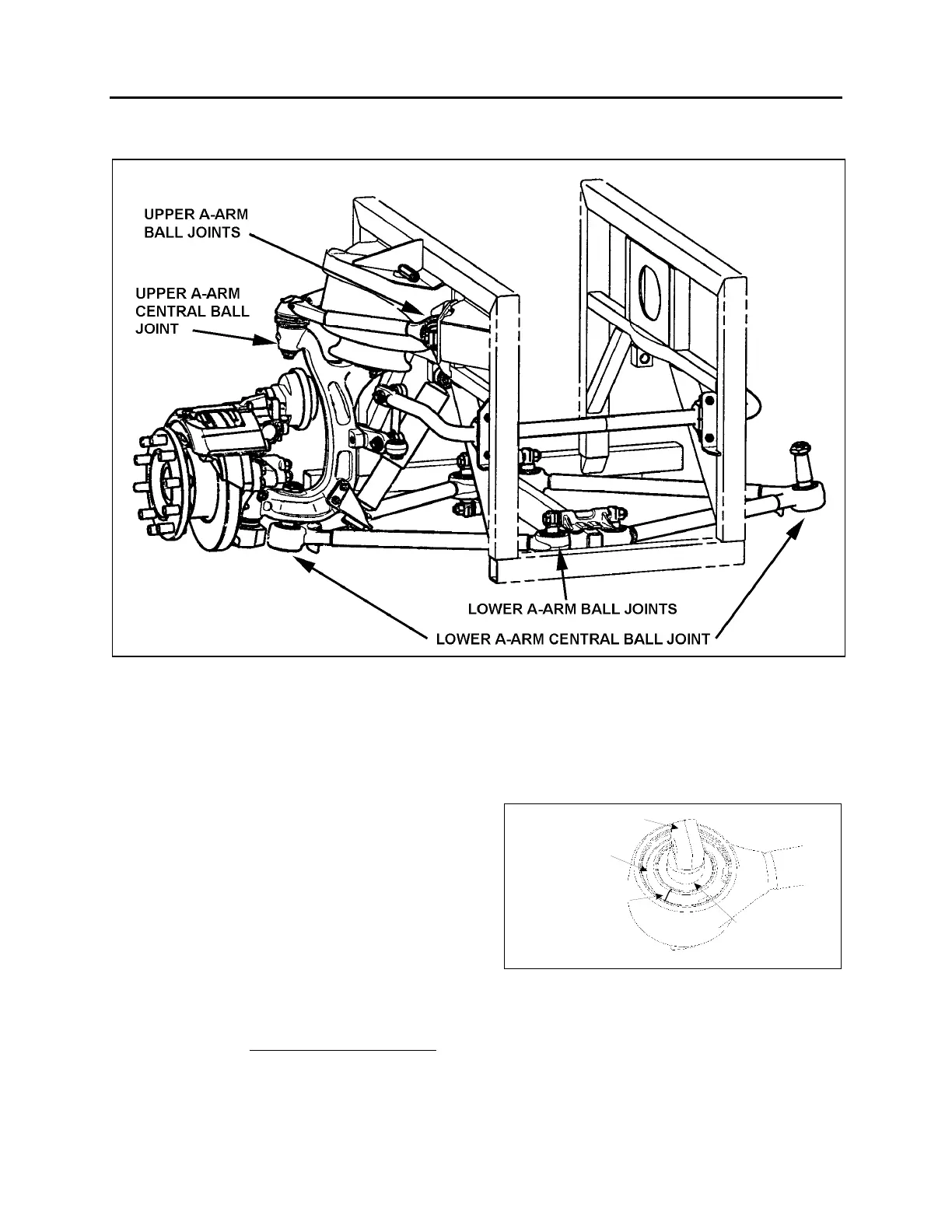

Ball pin

External joint shell

Radial cracking of the

sheet-metal race

Partial separation

is permitted

FIGURE 24: A-ARM BALL JOINTS 16173

3.13.2 Stripping Down

Strip down the defective joint through removal of

retaining ring, annular spacer and ball

pin/bushing, assembly and thereafter clean out

housing bore and locking circlips groove.

Loading...

Loading...