143

6.1.2 How to align machinery trains

The following step-by-step approach is recommended for multiple element trains.

1. Measure alignment at each coupling

2. Display results and optimize corrections (by defining ‘stationary’ machine feet)

3. Align the two machines at the first coupling position (remount sensors if

necessary). The Live Move function is used to perform foot corrections.

4. Check alignment results

5. Align the two machines at the next coupling position, then repeat alignment

check

6. Repeat step 5 until all machines have been aligned.

6.1.3 Measurement

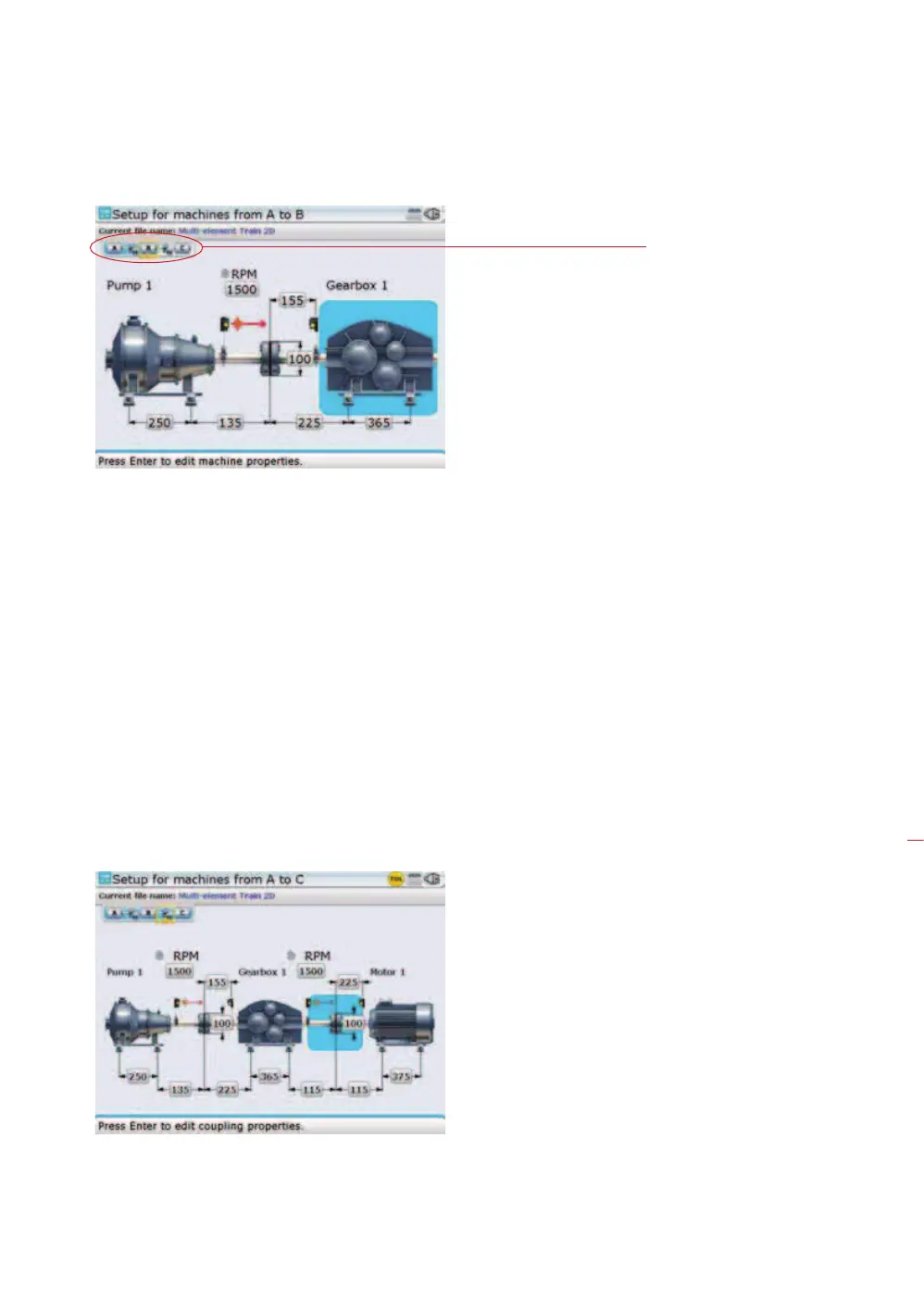

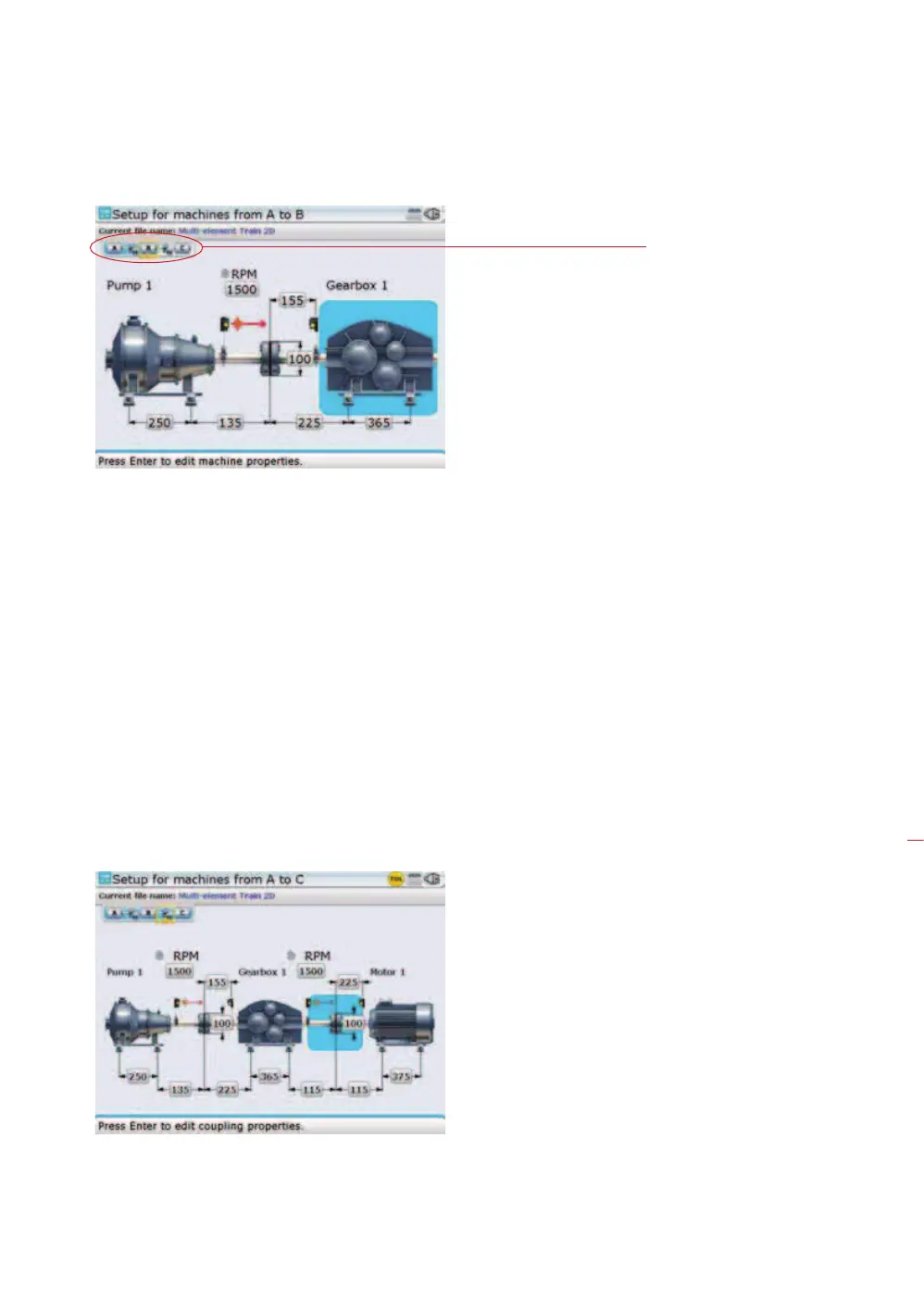

1. While in the set-up screen, use

f to zoom out the machine train. Pressing

the key repeatedly will zoom out until the entire machine train fills the display

screen.

2. Use

h/i to select the machine coupling to be measured first.

3. Ensure sensALIGN laser is mounted on the left side of the selected coupling.

A machine train of up to a

maximum of 14 machines

(13 couplings) can be

configured [Advanced /

Expert Shaft]. You may

view the entire machine

train at once through

the ‚zoom out‘ function

[

f], however, the

maximum number of

machines for which all

dimensions can be viewed

at one time is 5 machines

(4 couplings) Simply use

h/i to scroll through

the machines in the train.

To view any respective part

of the train closely, highlight

the section using

h/i

then zoom in by pressing

g.

The yellow focus shows

the machine train element

on which the blue cursor

is presently placed.

Machine train

Loading...

Loading...