P3: Basic PLC Program for SINUMERIK 840D sl

13.13 Block descriptions

Basic Functions

1032 Function Manual, 09/2011, 6FC5397-0BP40-2BA0

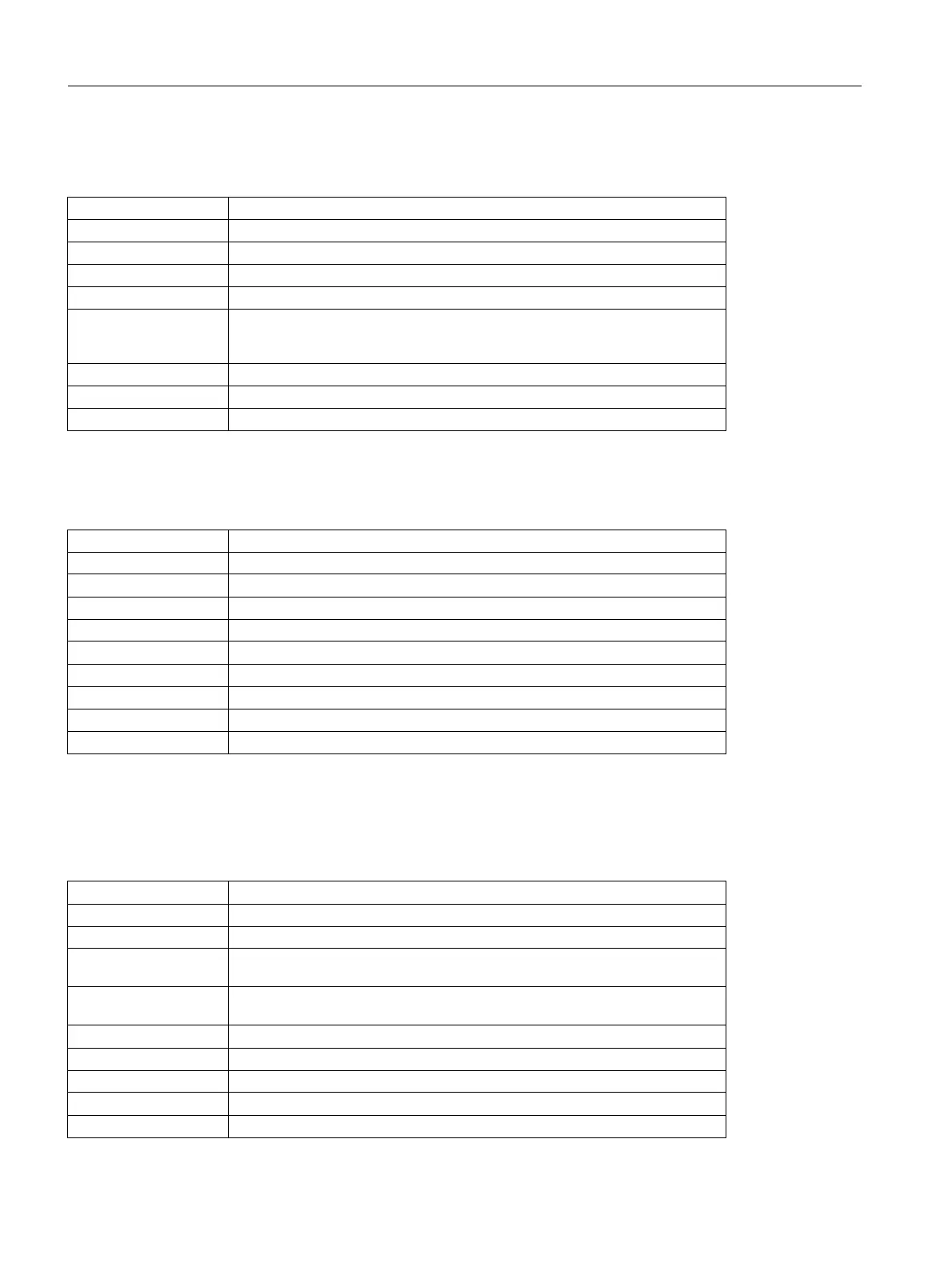

5 to 8. Position axes:

The following signals are relevant:

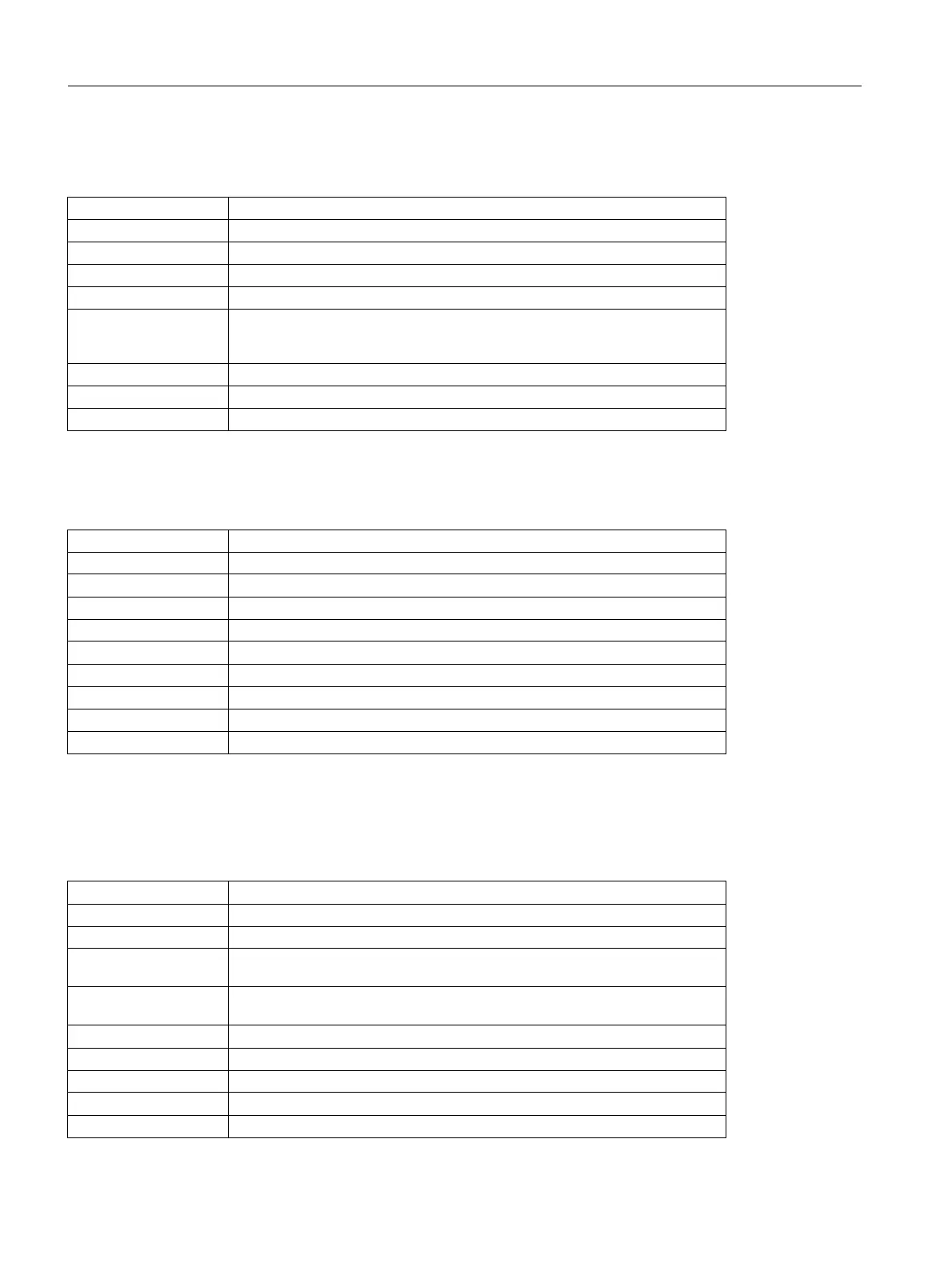

9. Rotate spindle with automatic gear stage selection:

The following signals are relevant:

10/11. Rotate spindle with constant cutting rate:

The "Constant cutting rate" function must be activated by the NC program in order for this to be executed.

The following signals are relevant:

Start: Initiation signal

Funct: "5 to 8" = Position axes

Mode: Positioning mode 0, 1, 2, 3, 4

AxisNo: Number of machine axis

Pos: Position

FRate: Positioning speed; if FRate = 0,

the value is taken from machine data POS_AX_VELO

(unit as set in machine data).

InPos: Is set to "1" when position is reached with "Exact stop fine".

Error : With positioning error = "1"

State : Error code

Start: Initiation signal for start rotation

Stop: Initiation signal for stop rotation

Funct: "9" = Rotate spindle with gear stage selection

Mode: Positioning mode 5 (direction of rotation M4)

Positioning mode < >5 (direction of rotation M3)

AxisNo: Number of machine axis

FRate: Spindle speed

InPos: Setpoint speed is output

Error : With positioning error = "1"

State : Error code

Start: Initiation signal for start rotation

Stop: Initiation signal for stop rotation

Funct: "B#16#0A = Rotate spindle with constant cutting rate (m/min)

Funct: "B#16#0B = Rotate spindle with constant

cutting rate (feet/min)

Mode: Positioning mode 5 (direction of rotation M4)

Positioning mode < >5 (direction of rotation M3)

AxisNo: Number of machine axis

FRate: cutting rate

InPos: Setpoint speed is output

Error : With position error = "1"

State : Error code

Loading...

Loading...