A2: Various NC/PLC interface signals and functions

1.2 NC/PLC interface signals

Basic Functions

42 Function Manual, 09/2011, 6FC5397-0BP40-2BA0

DB31, ... DBX1.4 (follow-up mode)

"Follow-up mode" is only effective in conjunction with the NC/PLC interface signal:

DB31, ... DBX2.1 (controller enable)

Function: Follow-up

During follow-up, the setpoint position of the machine axis is continuously corrected to the actual position

(setpoint position = actual position).

The following interface signals have to be set for the follow-up function:

DB31, ... DBX2.1 = 0 (controller enable)

DB31, ... DBX1.4 == 1 (tracking mode)

Feedback:

DB31, ... DBX61.3 = 1 (follow-up mode active)

During "follow-up", clamping or zero-speed monitoring are not active.

Function: Hold

The hold function does not correct the setpoint position of the machine axis to the actual position. If the machine

axis moves away from the setpoint position, a following error (difference between setpoint and actual position) is

generated. This error is corrected "suddenly" when the controller enable is set by the position controller, without

observing the axial acceleration characteristic.

The following interface signals have to be set for the hold function:

DB31, ... DBX2.1 = 0 (controller enable)

DB31, ... DBX1.4 = 0 (follow-up mode)

Feedback:

DB31, ... DBX61.3 = 0 (follow-up mode active)

During "hold", clamping or zero-speed monitoring are active.

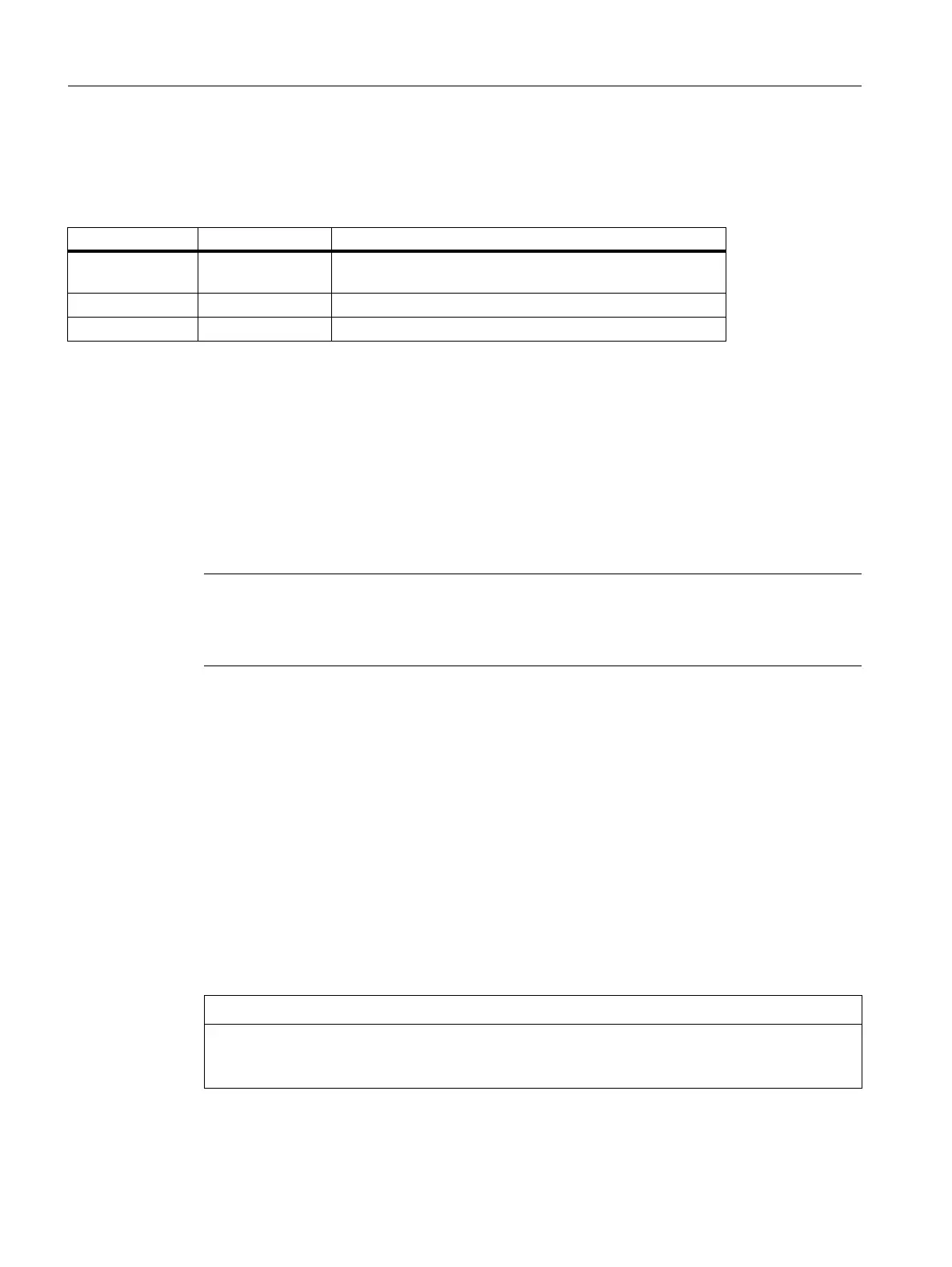

DB31, ... DBX2.1 DB31, ... DBX1.4 Function

1 Ineffective Normal operation (machine axis in closed-loop control

mode)

0 1 Follow-up

00 Hold

Note

When the controller enable is set from follow-up mode, if the part program is active, the last

programmed position is approached again internally in the NC (REPOSA: Approach along line

on all axes). In all other cases, all subsequent movements start at the current actual position.

NOTICE

With the "hold" function, once the controller enable has been set, the setpoint/actual-value

difference is corrected: directly by the position controller, i.e. without following the axial

acceleration characteristic.

Loading...

Loading...