Preface

Basic Functions

6 Function Manual, 09/2011, 6FC5397-0BP40-2BA0

Quantity structure

Explanations concerning the NC/PLC interface are based on the absolute maximum number of sequential

components:

• Mode groups (DB11)

• Channels (DB21, etc.)

• Axes/spindles (DB31, etc.)

Data types

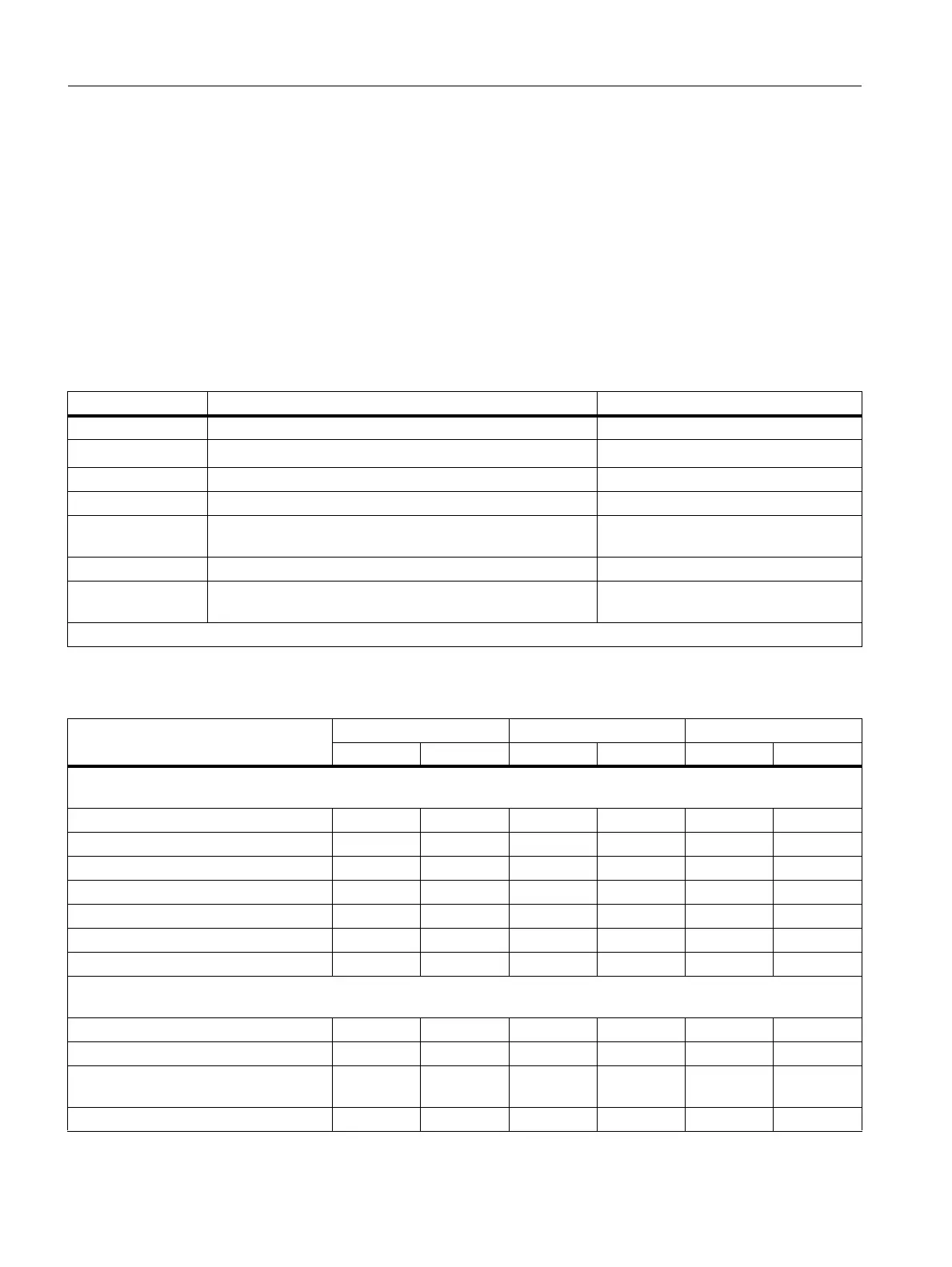

The following elementary data types are used in the control system:

SINUMERIK 828D system performance (region)

Type Meaning Value range

INT Signed integers -2147483648 ... +2147483647

REAL Figures with decimal point acc. to IEEE

±(2,2*10

-308

… 1,8*10

+308

)

BOOL Truth values TRUE (1) and FALSE (0) 1, 0

CHAR ASCII characters Corresponding to code 0 to 255

STRING Character string, number of characters in [...] Maximum of 200 characters (no special

characters)

AXIS Axis names only All axis identifiers in the channel

FRAME Geometrical parameters for moving, rotating, scaling, and

mirroring

Arrays can only be formed from similar elementary data types. Up to 3-dimensional arrays are possible.

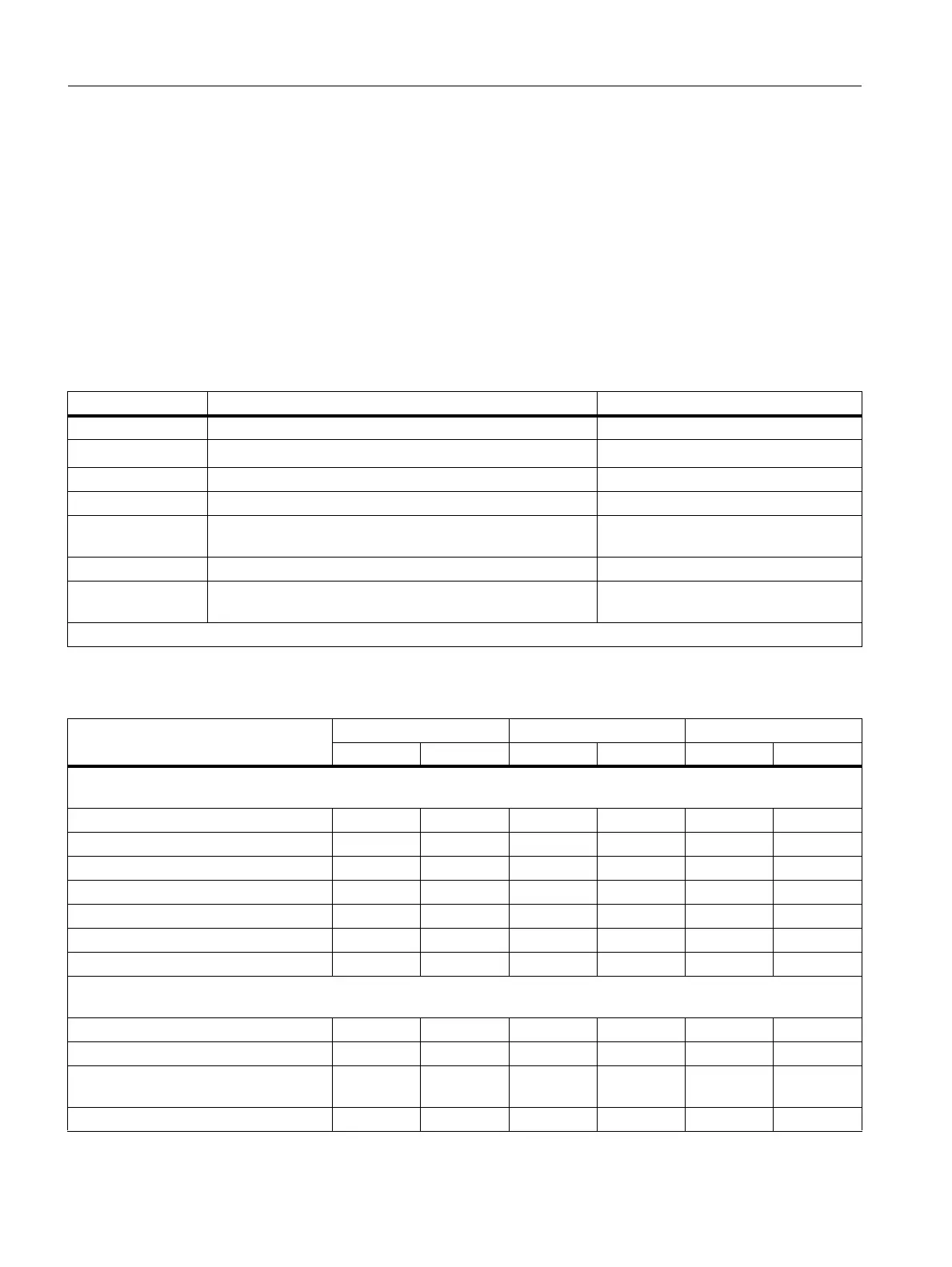

PPU240.2 / 241.2 PPU 260.2 / 261.2 PPU 280.2 / 281.2

BASIC T BASIC M T M T M

System performance

Basic quantity of axes/spindles 3 4 3 4 3 4

Max. number of axes/spindles 5 5 6 6 8 6

Max. number of interpolating axes 4 4 4 4 4 4

Max. number: Channels / mode groups 1/1 1/1 1/1 1/1 1/1 1/1

Min. block change time ∼ 9ms ∼ 9ms ∼ 6ms ∼ 6ms ∼ 6ms ∼ 3ms

Speed/current control cycle 125µs 125µs 125µs 125µs 125µs 125µs

CNC user memory (buffered) 1 MB 1 MB 3MB 3MB 5MB 5MB

CNC functions

Tool Management ● ● ● ● ● ●

Number of tools/cutting edges 80/160 80/160 128/256 128/256 256/512 256/512

Max. number of ASUBs (permanently

set)

222222

TRANSMIT / TRACYL ○○○○○○

Loading...

Loading...