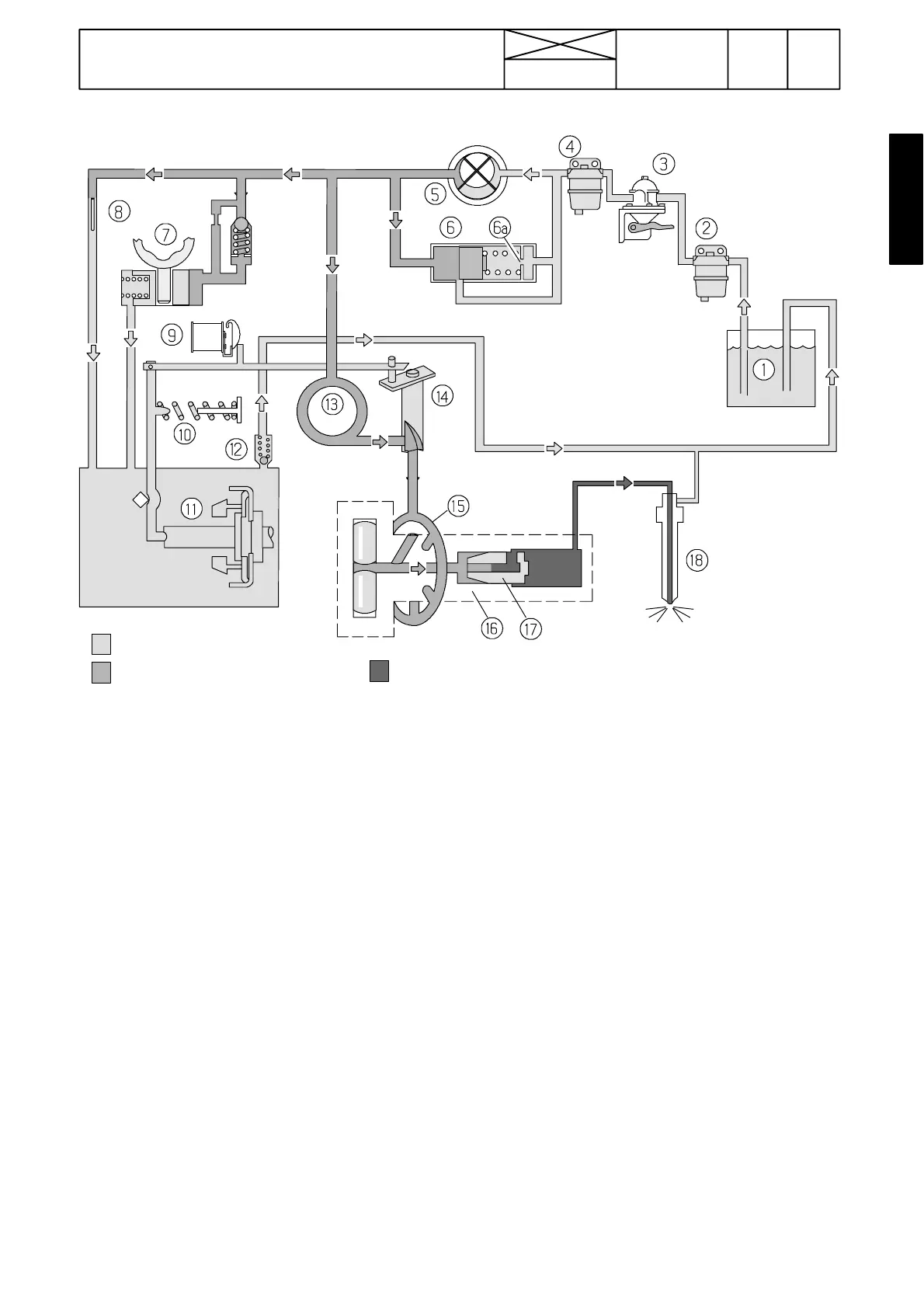

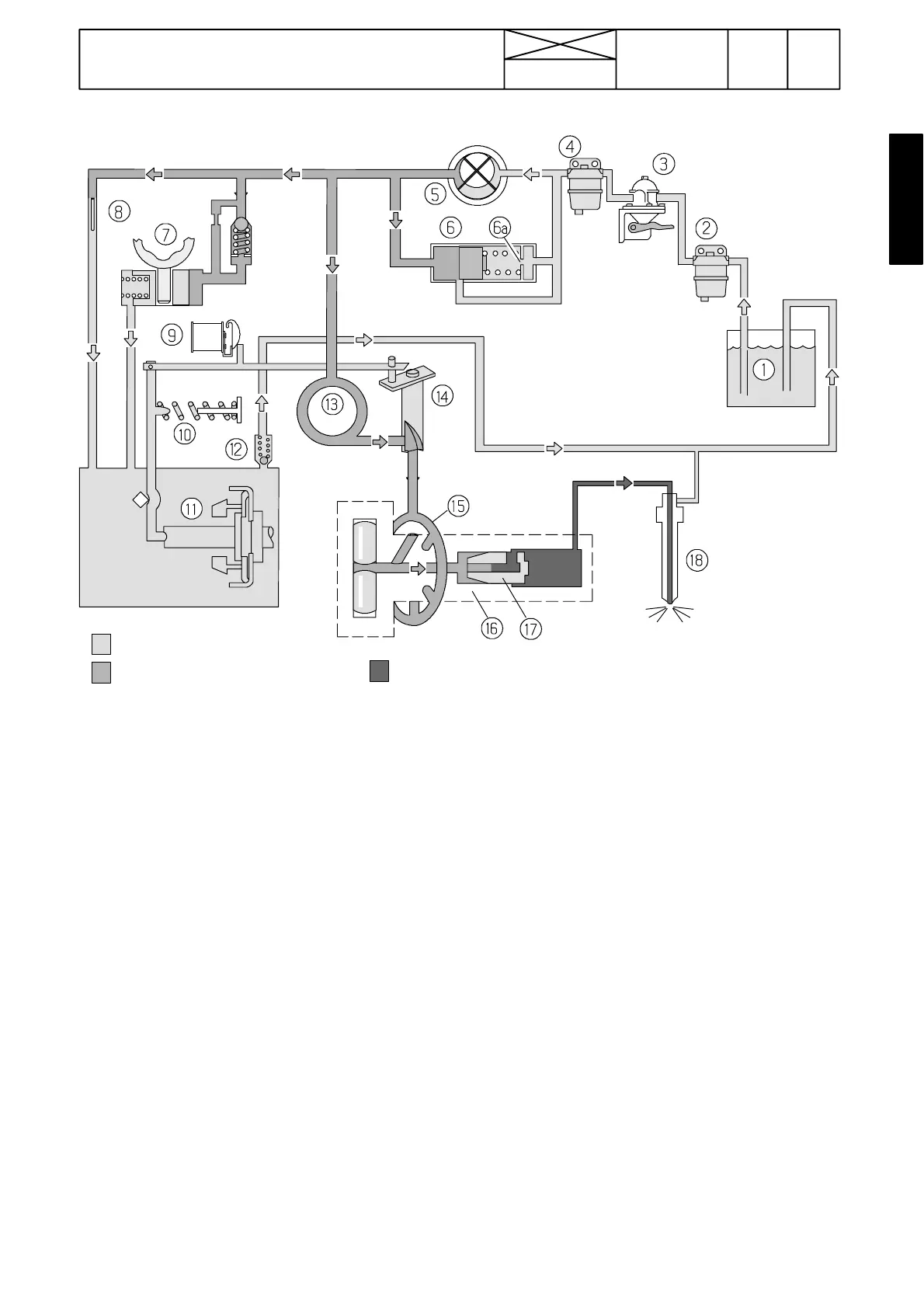

The fuel feed pump draws fuel from the tank via the water trap

and the filter into the fuel injection pump.

In the pump fuel flows through the inlet filter screen into the

vane type fuel transfer pump. Some fuel is bypassed through

the pressure regulator assembly to the suction side.

Fuel under transfer pump pressure (1---6 bar) flows through

the center of the transfer pump into the circular groove on the

rotor. It then flows through a connecting passage in the head

to the automatic advance and up through a radial passage

and then through a connecting passage to the metering

valve. The metering valve adjusts amount of injectedfuel and

position of the metering valve is controlled by the governor

(revolution lever) and the stop solenoid. From the metering

valve fuel flows to the radial charging passage and further to

the head charging ports.

As the rotor revolves, the two rotor inlet passages register

with the charging ports in the hydraulic head, allowing fuel to

flow into the pumping chamber. With furtherrotatio n, the inlet

passages close and the port to the injectors opens.

Function

While the discharge post is opened, the rollers contact the

cam lobes forcing the plungers together. Fuel trapped

between the plungers is then pressurised and delivered by

thenozzletothecombustionchamber.

The injection pump is self---lubricating, and it has not been

connected to the engine lubricat i on system.

As fuel at transfer pump pressurereachesthe charging ports,

slots on the rotor shank allow fuel and any entrapped air to

flow into the pump housing cavity. In addition, an air vent

passage in the hydraulic head connects the outlet side of the

transfer pump with the pump housing. This allows air and

some fuel to be bled back to the fuel tank via the overflow

valve.

The fuel thus bypassed fills the housing, lubricates the inter-

nal components, cools and carries off any small air bubbles.

The pump operates with the housing completely full of fuel;

there are no dead air spac es anywhere within t he pump.

103

Model Code Page

22. Fuel system

15. 5. 1996

8050--8550 220 13

Stanadyne distributor pump

Transfer pump pressure Injection pressure

Housing pressure

1. Fuel tank 10. Regulator spring

2. Water trap 11. Centrifugal weights

3. Fuel feed pump 12. Overflow valve

4. Fuel filter 13. Hydraulic head connecting passage

5. Transfer pump 14. Metering valve

6. Pressure regulator valve 15. Hydraulic head charging pasage

7. Automatic advance 16. Distributor rotor

8. Air vent passage 17. Delivery valve

9. Stop solenoid 18. Injector

Loading...

Loading...