450

Model Code Page

31. CareTel

1. 4. 1997

6000--8750 361 2

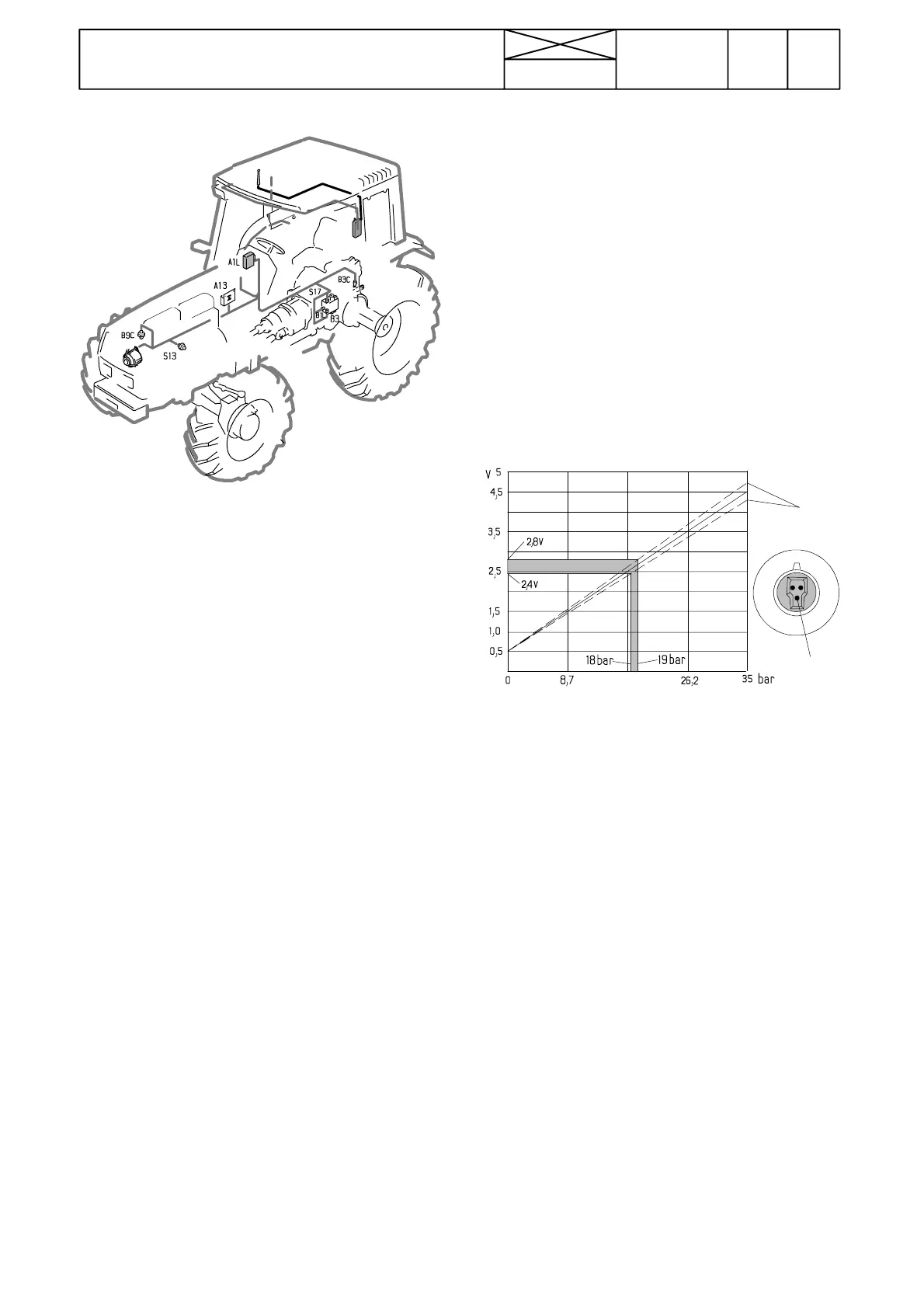

2. Sensors

a) Engine oil pressure sensor S13

Transmission oil pressure sensor S17

When the lubricating oil pressures drop under a certain

level, the sensors ground the electric circuit and a warning

light in question comes on in the dashboard (LOW). When

the pressure rises up to a certain level, the sensor cuts off

the circuit and the warning light goes out (OK).

Start the engine and ensure that the warning lights do not

light. Disconnect the sensor wire and connect it to tractor

frame at which time the warning light in question comes on.

Connect the wire to the sensor pin and the warning light

should go out.

Stop the engine, at which time the warning lights come on

and light if the current is switched on. If the warning lights

function as shown above, the sensors and wires are prob-

ably in order.

b) Engine temperature sensor B9C

Resistance values of the sensor:

--- 120---148 Ω (+60˚C)

--- 4 7 --- 5 6 Ω (+90˚C)

--- 3 5 --- 4 2 Ω (+100˚C)

(the resistance increases when temperature lowers).

CareTel temperature value can be compared with the read-

ing of the dashboard temperature gauge at which time can

be estimated the size class of the value. The working tem-

perature of the engine varies between +75...+95˚C

according to loading. Engine coolant temperature can be

measured with an auxiliary thermometer, at which time is

obtained a more accurate value of comparison.

c) Transmission oil temperature sensor B3

Resistance values of the sensor:

--- 200---250 Ω (+60˚ C)

--- 7 5 --- 9 0 Ω (+90˚ C)

(the resistance increases when temperature lowers).

If the tractor is equipped with Agrodata---instrument, the

function of this sensor can be checked by ensuring that the

AD---instrument shows a correct temperature value, see

code 331.

In the dashboard there is a warning light for too high tem-

perature in the transmission. Transmission oil working tem-

perature varies between +60...+85 ˚C according to the

loading.

d) PTO shaft rotation speed sensor B7

Resistance of the sensor should be 1,0---1,10 kΩ.

If the tractor has AD---instrument, check whether it shows

the PTO revs. If it shows the revs and the reading reacts to

the alterations of the revs, the sensor is in order.

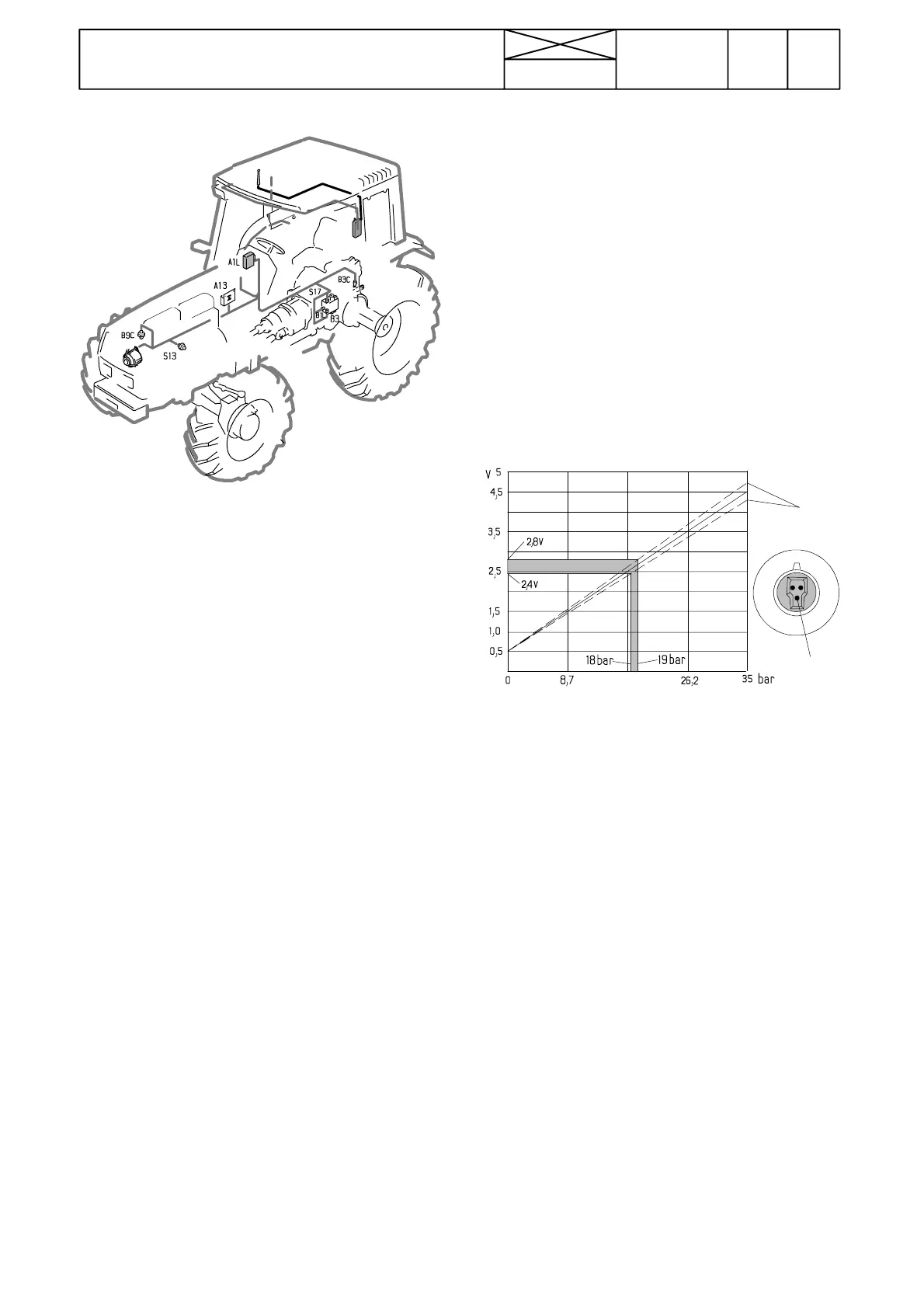

e) Pressure sensor B1L for low pressure circuit

The basic pressure of this circuit is 18 ---19 bar. The circuit

maintains clutch pressures in various transmission multi---

disc clutches, such as DPS, lock, 4WD, PTO, see pages

911/1---2. Sensor output voltage (DC) depends on the pres-

sure linearly, see diagram below. The connector must be

connected to the sensor when measuring output voltages.

Allowable

deviation

Output

Others

Engine revs and running hours

CareTel takes engine revs and running hours from the alter-

nator. In the dashboard there is a rev counter. If it seems to

function and reacts to the revs alterations, the measuring

circuit is in order.

CareTel running hour reading can be checked by compar-

ing it with the reading in the dashboard.

CareTel takes the engine running mode (*) from the igni-

tion switch position and engine revs (charging light), so that

when the engine revs are over 400 r/min, CareTel assumes

that the engine is running, if the ignition switch is in the run-

ning position.

Engine moment and Σ-- power

These functions only on 8750 tractor, which has Σ--- pow er,

see under code 313.

In point SP there is ON, when the engine is working in the

higher output range, at which time also the dashboard

ETB---light lights, otherwise OFF.

CareTel shows the engine torque as percents of the total

torque.

Loading...

Loading...