1241

Model Code Page

90. Hydraulic system

1. 11. 1998

6000--8750 911 1

1. 1. 1995

Repair instructions

1. Low pressure circuit

(Op. no. 911)

A. Measuring pressure

1. Start the engine and run it at 1500 revs/min.

2. Warm up the transmission/hydraulic oil to 40---65˚C.

Note! The oil warms up faster if the steering wheel is held

against the stop.

3. Disengage as many servo functions as possible (clutches

unpressurised in order to eliminate a pressure drop caused

by leakages in clutch piston seal s).

Note! When the 4WD is engaged, the clutch is unpressurised.

On 2---step speedshift should theTORTOISE range be enga-

ged (Trac---Trol) or HARE range engaged (Overdrive). On

HiTech models the shuttle must be in the neutral position. Two

DPS clutches are always pressurised,when the engine is run-

ning.

Pressure---test point

Pressure---limiting valve

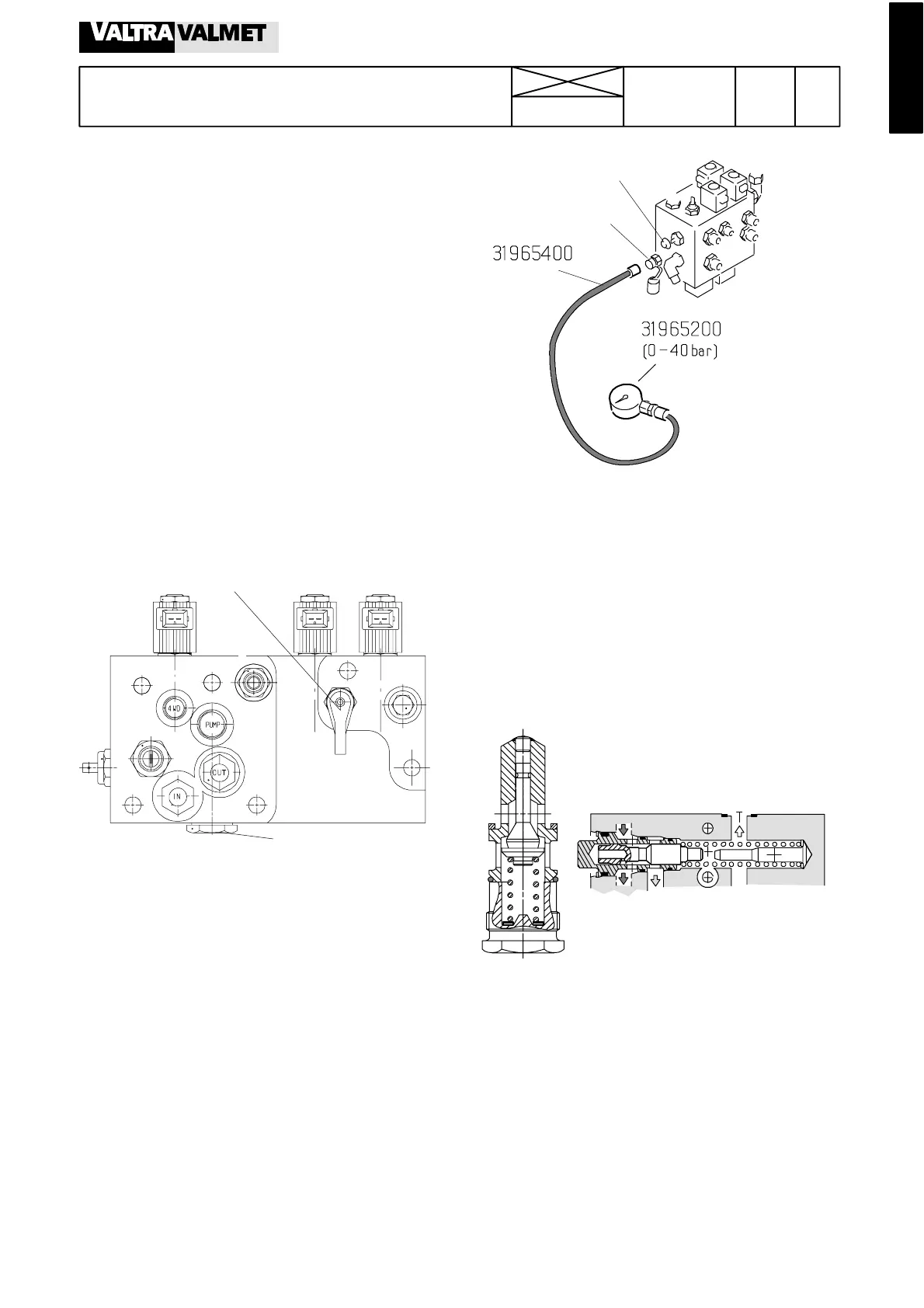

4a. Earlier valve block (---660070): Connect a pressure gauge

to the test point on the servo valve block (on the LH side of the

gearbox). Read the pressure. It should be between 2,1---2,3

MPa. Pressure measuring equipment, see page 910/5.

Pressure---limiting valve

Pressure---test point

4b. Later valve block (660071---): Connect a pressure gauge

to the test point on the servo valve block and read the pres-

sure value. It should be 1, 8 ---1,9 MPa.

4c. On tractors which have been equipped with HiTech Shut-

tle, the low pressure circuit test point is placed on the outer

face of the valve block, see page 440/24. The pressure value

is 1,8---1,9 MPa.

Note! These pressures are maintained by the low pressure

limiting valve and seals at various soleno id valves (and clutch

piston seals in pressurised clutches).

Pressure---limiting valves (1,8 MPa)

---660070

660071---

5. If the pressure gauge reading deviates much from the cor-

rect value, the fault can lie in the pressure---limiting valve orthe

low---pressure pump is worn out. Also excessive leakage can

cause pressure loss.

6. Then activate each service in turn. The pressure should

momentarily drop but quickly re---stabilise. A constant pres-

sure drop of about 0,1---0,2 MPa indicates excessive leakage

and therefore pressure loss in that service.

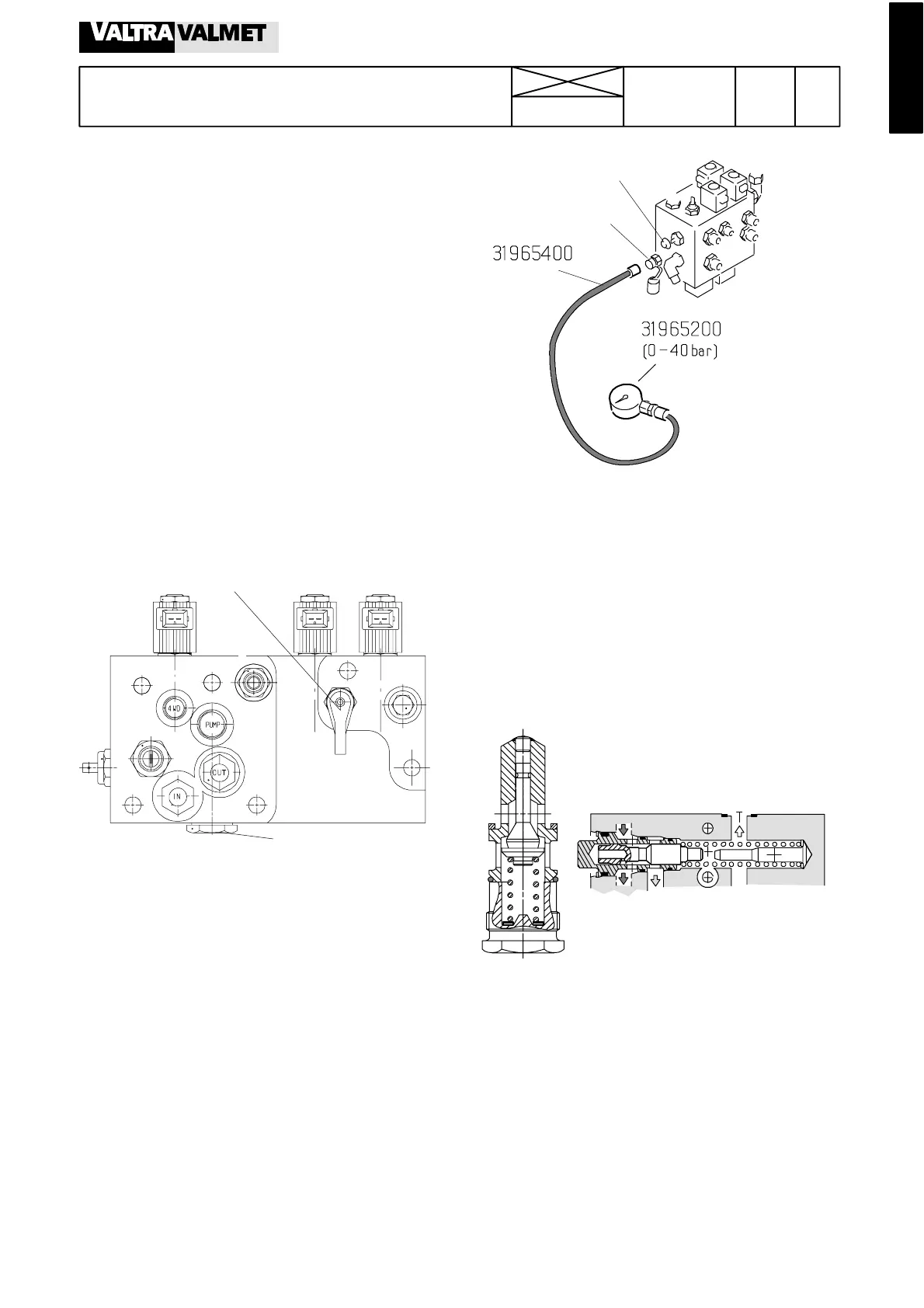

Note! Pressure measuring equipment, see page 910/5. It is

available a pressure---test kit which order no is 31965000. It

includes all equipment needed for pressure measurement on

Valmet tractors. The parts can also be ordered separately.

Loading...

Loading...