119

Model Code Page

22. Fuel system

1. 8. 1998

8050--8550 223

11

1. 4. 1997

C. Bleeding fuel system

Note! This fuel system removes automatically small amounts

of air bubbles from the filter and the pump when the engine

is running. However, bleed the system always, when the sys-

tem has been opened orfuel has been exhausted during driv-

ing or a new spare pump has been fitted (toavoid long starting

time).

Metal gauze filter

under cover

1. Pump by hand the fuel feed pump lever. If the pumping

seems to be ineffective, turn the engine a little so that the cam-

shaftcamisnotatthefeedpumplifter.

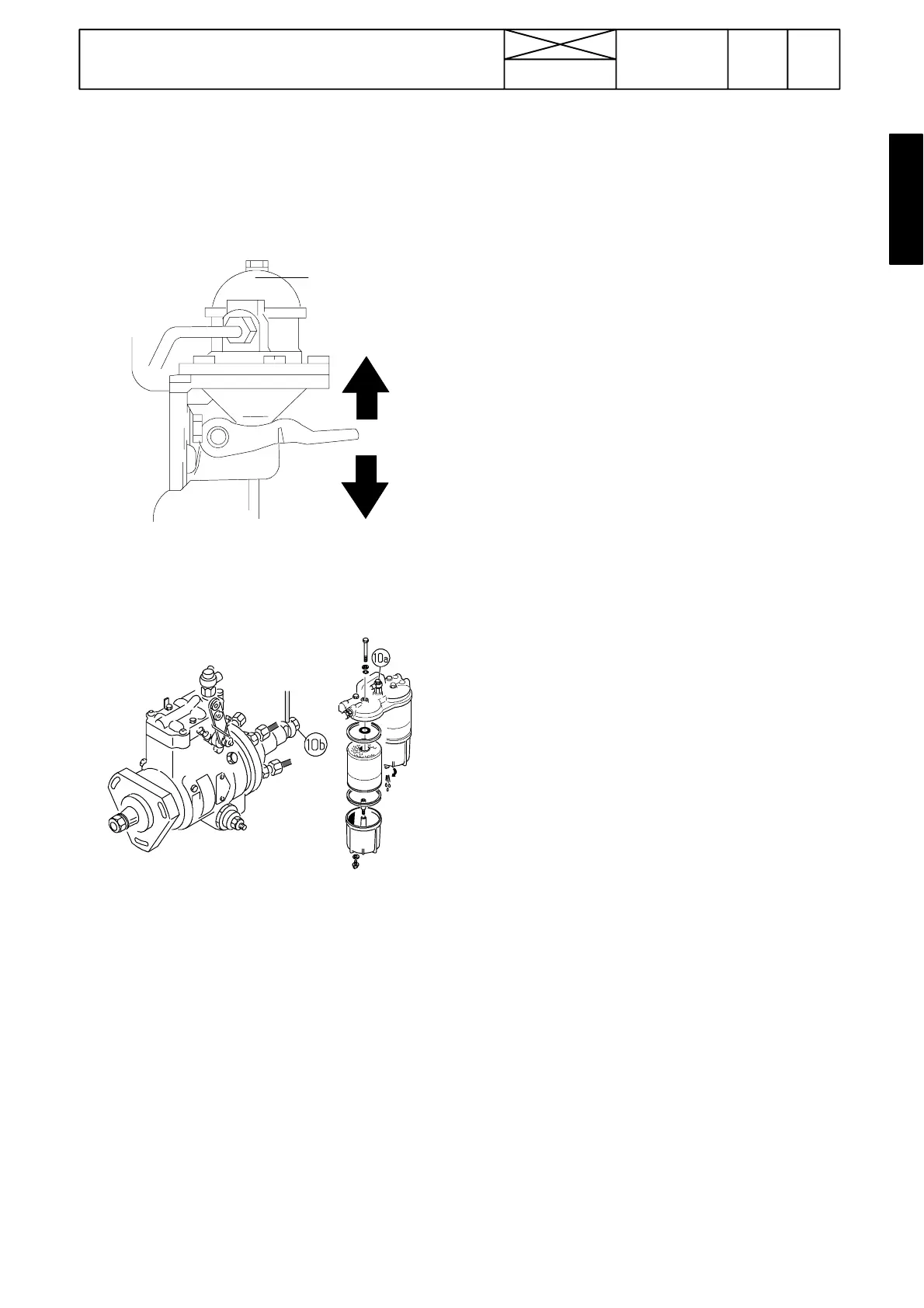

2. Loosen the bleeding screw (10a) on the filter. Pump with the

hand pump until no air bubbles flows out of the bleeding

screw hole. Tighten the bleeding screw.

3. Pump further with the hand pump and loosen the fuel inlet

connection (10b) on the pump, until the fuel coming out is free

from air bubbles. Tighten the connection.

4. Start the engine and assure, that no leaks exist.

Note! When the bleeding is done in this way, fuel flows

immediately into the internal transfer pump when the starter

motor is rotating and the distributor pump housing is filled

quickly with fuel. In the pump housing there is a stop solenoid,

which must not be switched on for longer periods when the

pump housing is empty of fuel.

D. Fuel feed pump

For the membrane type fuel feed pump no spare parts are

supplied. The feed pump must be changed for a new one, if

the feed pressure has dropped noticeably (rated feed pres-

sure is 0,2---0,5 bar at low idling speed and max 0,2 bar less

when engine is accelerating) or if the fuel feed pump has

been damaged.

Measuring fuel feed pressure

Measuring equipment, see page 220/3.

Note! If the feed pressure value is below the rated value,poss-

ible reason can be:

--- blocked fuel filter/fuel feed pump metal gauze filter

--- faulty fuel feed pump

--- blocked or leaked fuel pipes or pipe connections

Important! Under the fuel feed pump cover there is a wash-

able metal gauze filter. If much impurities have gathered on

this filter, fuel cannot flow t o the feed pump and further to the

injection pump and t his caus es malfunctions in the fuel sys-

tem. Always when malfunctions appear, the feed pump cover

should be removed and the metal gauze filter must be

checked and cleaned.

Note! From manufacturing week G42 incl. the fuel feed pump

gasket no. 8366 40335 has been removed and the sealing has

been done with sealing glue T61050 (Weicon Lock AN

305---10 or 75), which must also be used in connection with

possible leakages. Run the engine, until the cylinder block

temperature is at least +60˚C. Clean the sealing surfaces well

by using suit able solvent. Apply the sealing glue onto the

pump sealing face and fasten the pump. Let the sealing glue

dry about one hour before the engine is started (if a fuel feed

pump, which has been tightened with the sealing glue,should

be changed, the pump fastening flange must be warmed up

to about +200˚C before removing the pump).

New fuel feed pump

In the tractor production has been started to fit a new fuel feed

pump (420: H7663---. 620, 634: H7728---), which has an

o---ring seal and four fixing bolts. This pump can be fitted also

on earlier manufactured tractors, although they should have

the earlier, with two bolts attached pump (mounting kit no.

8366 62052). In the cylinder block there are four fixing holes

from the beginning of the year 98. The Spare Part Centre dis-

patches only the new pump.

On the next page there is an instruction on, how to fit the new

pump.

Loading...

Loading...