93

Model Code Page

31. Σ --- p o w e r s y s t e m

1. 10. 1999

8750, 8950 313 7

1. 9. 2002

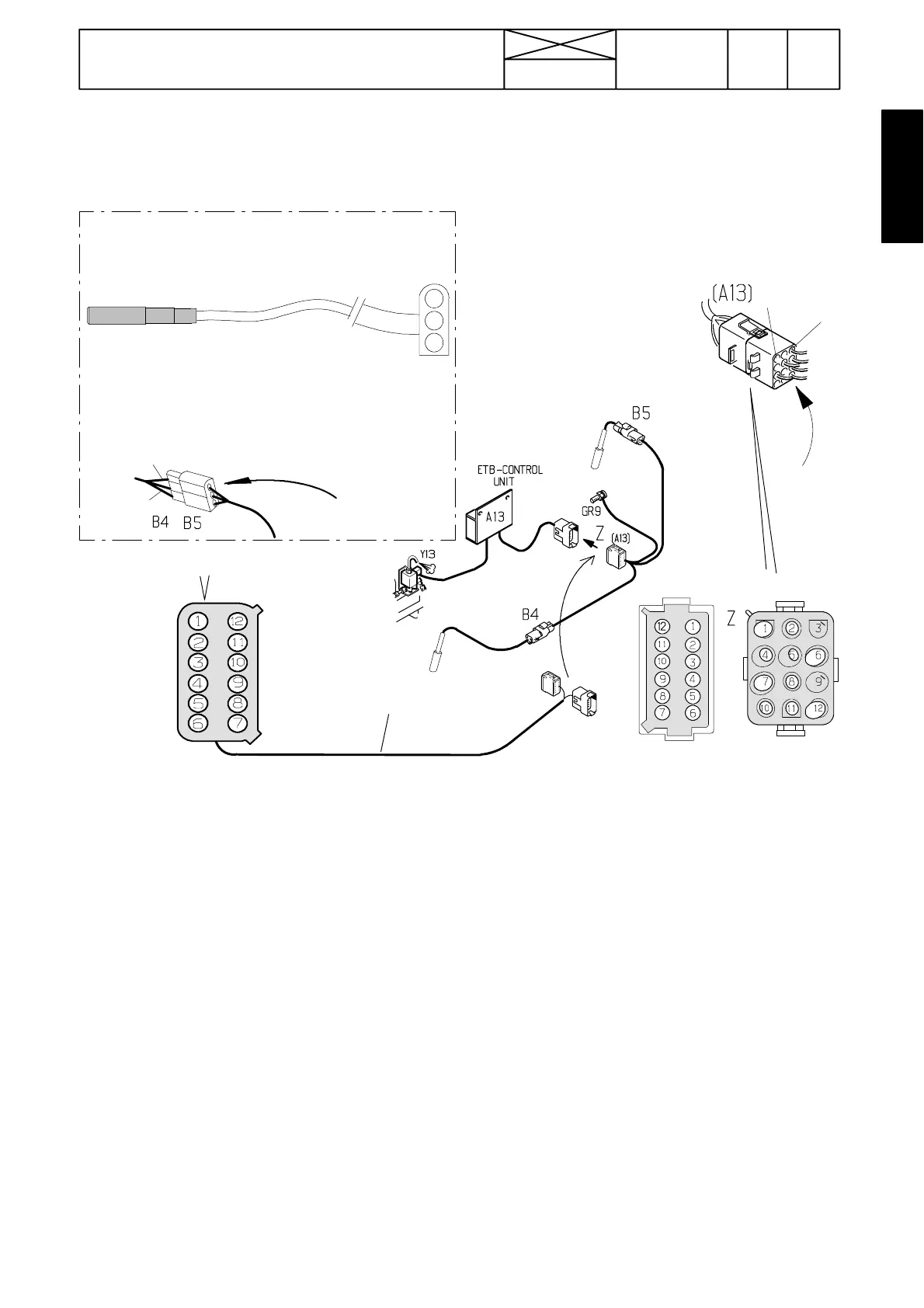

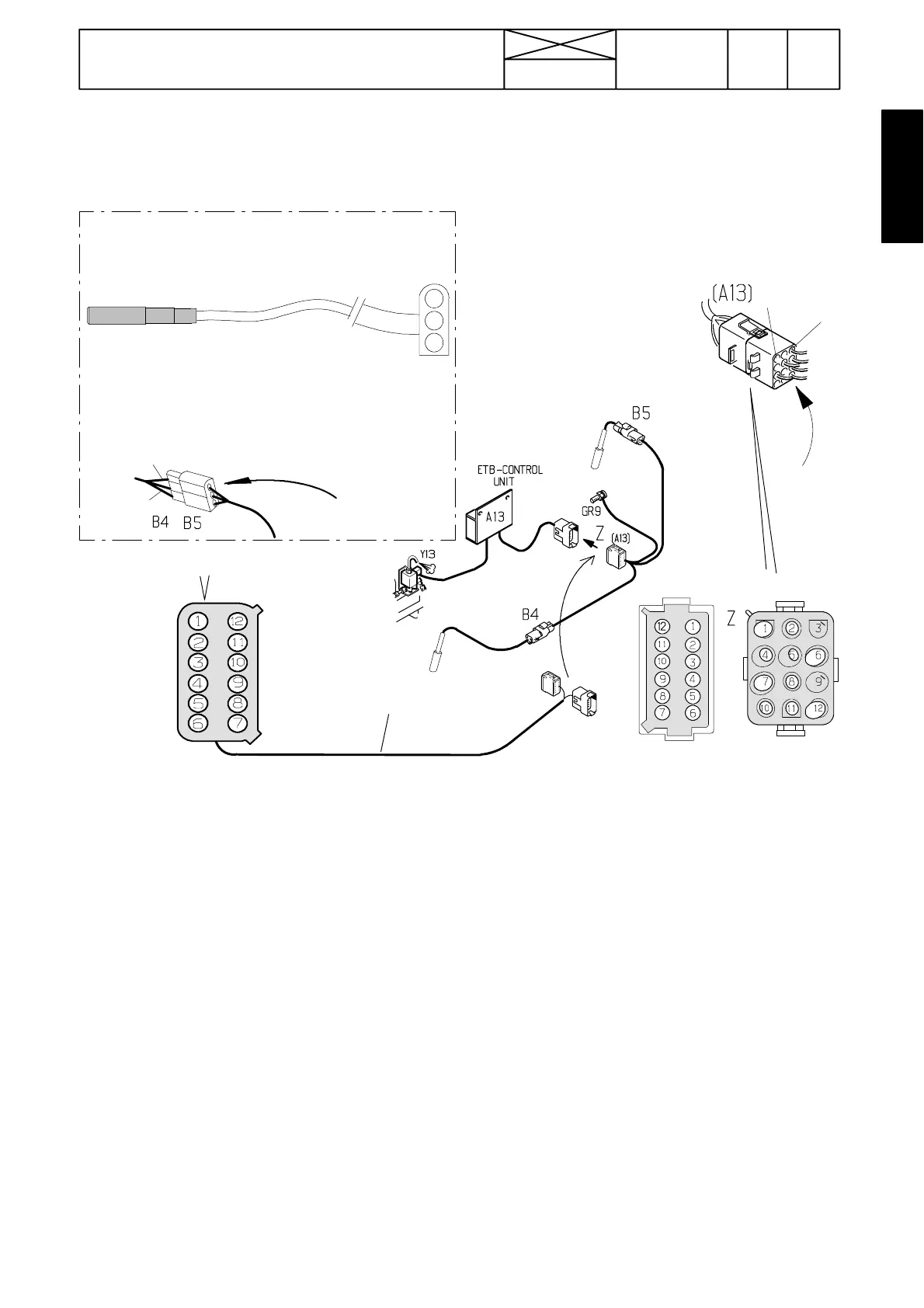

C. Fault tracing by measuring voltages

The lat est connect ors (G22507---) are tight, and connecto r rubber seals must not be opened, but the voltage measurements

are done by connecting ETV 894 310 into the wire loom. On the earlier connectors (---G22506) the measurements can be

done through the holes in connector A13 and/or through the holes in connectors B4 and B5. There are pin numbers o n the

connec tor hous ings.

Measure-

ments

---G22506

Measurements

G22507---

Measurements

---G22506

Earlier connectors (---G22506):sensorvoltagesare

measured from the connectors B4 and B5 through holes

on them while the current is switched on to the tractor:

Pins:

1<>2: supply 12---13 V (battery voltage). Earth.

2<>3: sensor signals

--- s i g n a l 0 , 7 --- 3 V a t t h e n o t c h , o t h e r w i s e 0 , 2 --- 2 V b e l o w

battery voltage.

1

2

3

1=+12 V (Brown)

2= Earth (Green)

3=Sign (White)

1

3

3

1

/

G22507---

---G22506

ETV 894310

+12

ETB

Sign PTO

GR9

Sign Eng

GR9

%display

PTO on/off

GR9

GR9

*)

*)

*)

*) Not in ver-

sions 2.0

If the Σ ---Power has malfunctions , disconnect connectors B4, B5 and A13 and reconnect them, so that possi ble poor con-

tacts disappear. If the malfunctions still exist, carry out t he following voltage measurements:

Earlier connectors ( ---G22506): Carry out measurements through the holes in the connectors.

The latest connectors (G22507---): Connect measuring cable ETV 894 310 between t he control unit connector A13 and

carry out measurements from the measuring cable connector.

Switch on current to the tractor and carry out the following measurements:

Pins

+<> --- measure battery voltage from the battery terminals (12---13 V)

1<>5 supply voltage (battery voltage) into the control unit, control unit earthing

1<>7 Versions 1.0 and 1.1: supply voltage (battery voltage) into the sensors, sensor earthing

1<>4 Versions 1.0 and 1.1: supply voltage (battery voltage) into the sensors, sensor earthing

6<>5 signal from foremost engine sensor B4

3<>5 signal from rearmost PTO sensor B5

Versions 1.0, 1.1 and 2.0: signal 0,7--- 3 V at the notch, otherwise 0,2--- 2 V below battery voltage

1<>12 Versions 1.0 and 1.1: supply voltage (battery voltage), display earthing

9<>12 Versions 1.0 and 1.1: control of PTO and %--- display

--- supply voltage, when the PTO is engaged, otherwise 0 V

9<>5 Versions 2.0: co n t r o l o f P T O a n d % --- d i s p l a y

--- supply voltage, when the PTO is engaged, otherwise 0 V

Start the engine:

Pins

11<>12 Versions 1.0 and 1.1: control of %---display

--- when the PTO is engaged: µ 9V=display0%,µ 1V=display99%.

11<>5 Versions 2.0: control of % ---display

--- when the PTO is engaged: µ 9V=display0%,µ 1V=display99%.

2<>12 Versions 1.0 and 1.1: Control of ETB---light

--- >10 V, when the higher output range is on (>25---30 % in display), otherwise 0 V.

2<>5 Versions 2.0: Control of ETB---light

--- >10 V, when the higher output range is on (>25---30 % in display), otherwise 0 V.

Loading...

Loading...