2. Measuring i nternal voltages of position sensor and draft sensors

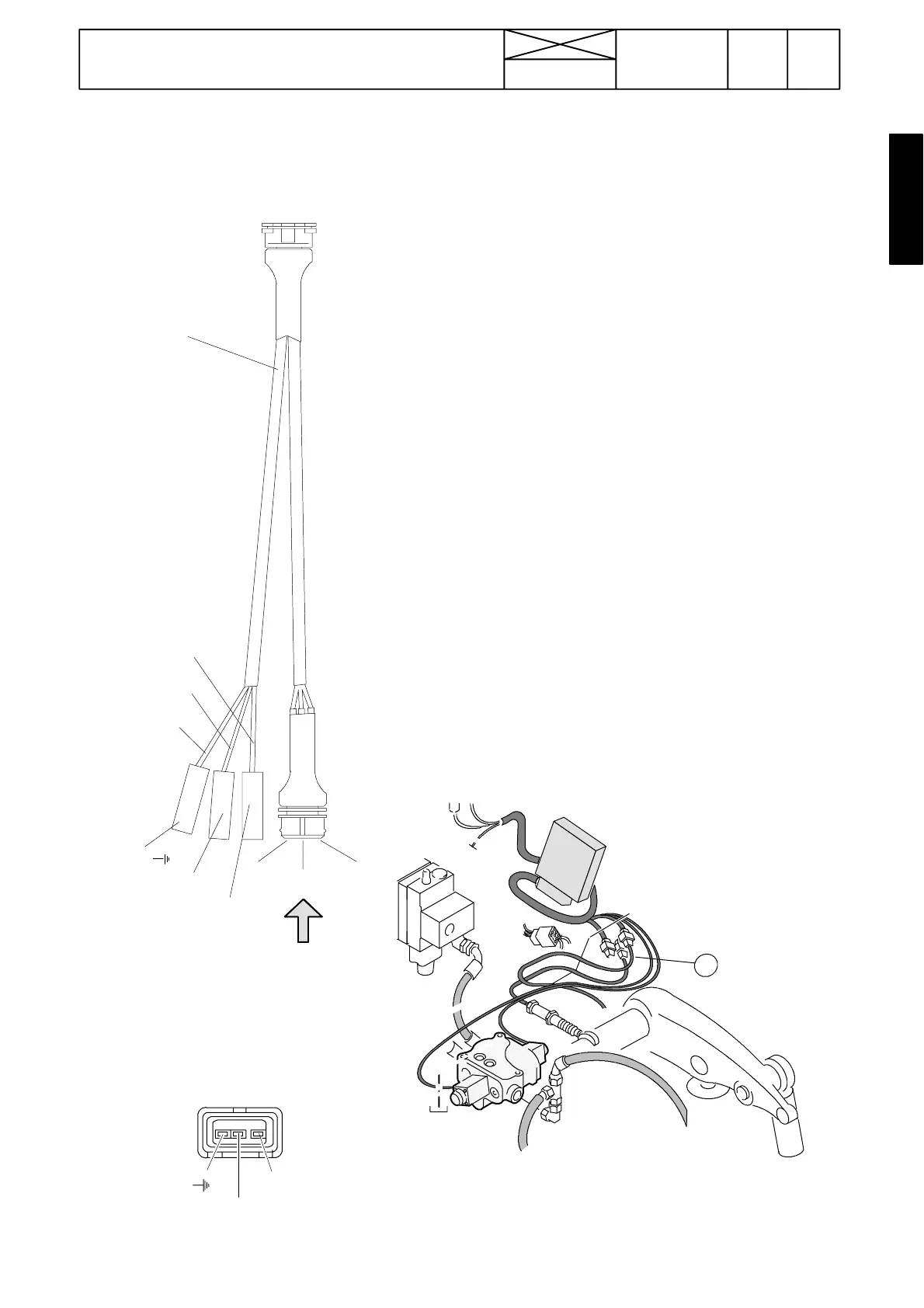

Figure 1. Tool for measuring the sensor voltages

Red = supply voltage=3

Blue = signal volt age=2

Black = earth lead=1

Red (3)

Blue (2)

Black (1)

The condition of the sensors can be checked by measuring

the sensor supply and signal voltages with the aid of a spe-

cial tool.

Connect the tool into the power lift by opening the position

sensor or one of the two draft sensors connectors and by

fitting the tool between the lead. Switch on current and acti-

cate the power lift with lift/lower switch.

The correct values should be:

Position sensor: (ACB / ACD)

--- Measure the sensor supply voltage in the alternating

current (AC) position of the multimeter. The value should be

between the red and black connectors: 6,3---7,7 VAC

--- Measure the sensor signal voltage in the alternating

current (AC) position of the multimeter. The value should be

between the blue and black connecto rs:

1,2...2,5 VAC lower links down.

3,0...5,0 VAC lower links up.

Draft sensors:(AC,ACB,ACD)

--- Measure the sensor supply voltage in the direct current

(DC) position of the multimeter. The value should be bet-

ween the red and black connectors: 9,5 --- 10,5 VDC

--- Measure the sensor signal voltage in the direct current

(DC) position of the multimeter. The value should be bet-

ween the blue and black connectors:

2,5 VDC max pull.

7,5 VDC max push.

5,0 VDC when lower links are unloaded..

Note! If the sensors do no t receive the supply voltage,

check the power lift fuses and the lead connectors. If these

areOKthepossiblefaultmaybeinsidetheAutocontrol

electronic unit which should be replaced.

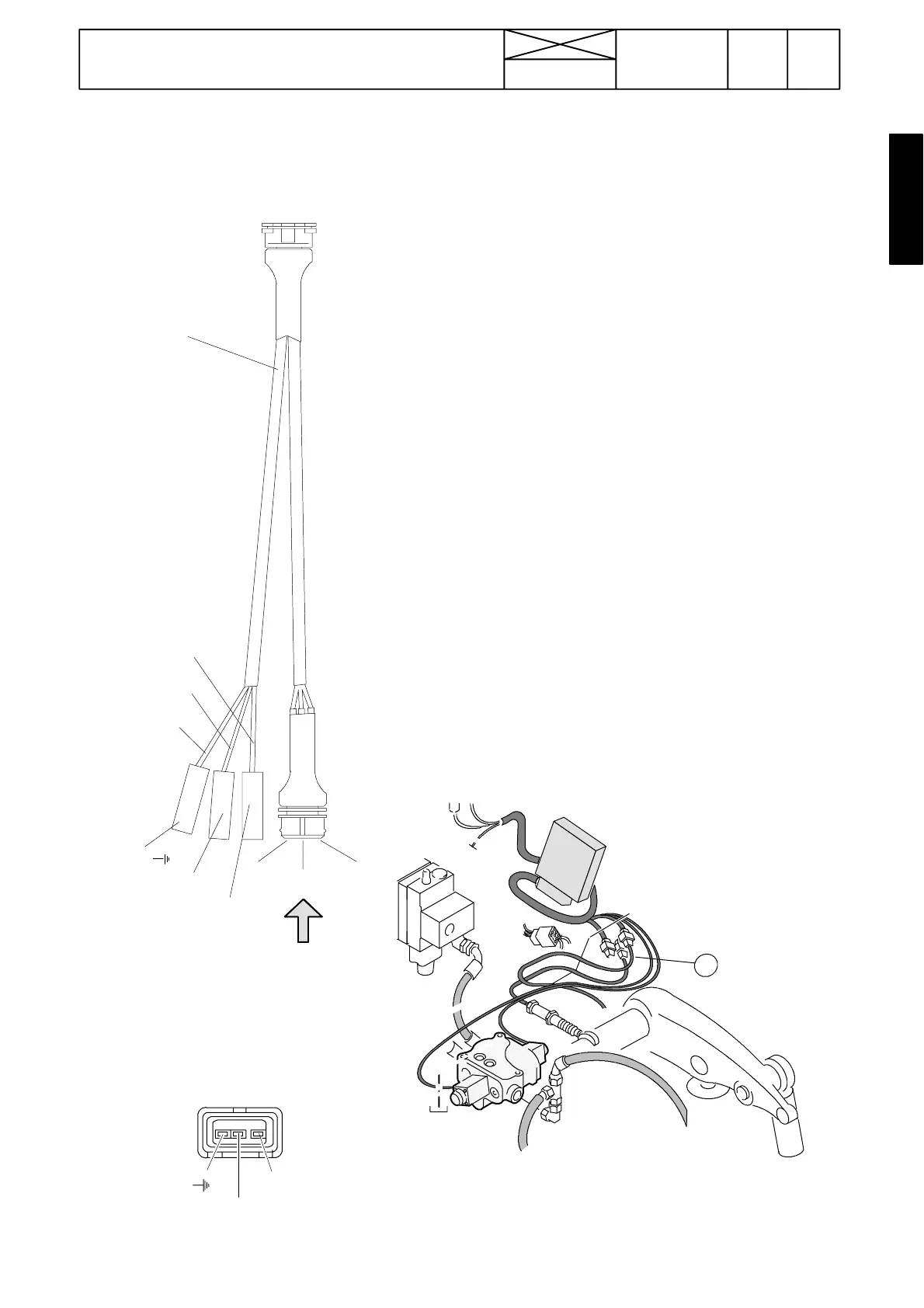

View A

Sensor connectors (A) are placed in the lever console in the

cabandareaccessibleafterremovingconsolesidepanel.

Order no

ETV 894 100

Blue

Yellow ---green

Brown

95

Model Code Page

32. Electro---hydraulic power lift

6000--8400 320 13

15. 5. 1996

1. 9. 2002

1

2

3

A

1

2

3

A

Loading...

Loading...