773

Model Code Page

442. Reverse shuttle

6000--8750 442 3

1. 1. 1995

15. 5. 1993

C. Fitting the reverse shuttle

1. Fasten the thrust bearing with universal grease to its place

on the gearbox input shaft front bearing cover. In connection

with the 2---step quick---shift gear, fasten the impulse disc (on

E---models only) and its support tube into the reverse shuttle

housing (o---ring fix the impulse disc but universal grease can

be used if necessary).

Note! Before fitting the reverse shuttle, ensure that the gear-

box layshaft front end cover has been fitted in the correct way

(otherwise it prevents the reverse shuttle layshaft from enter-

ing fully home).

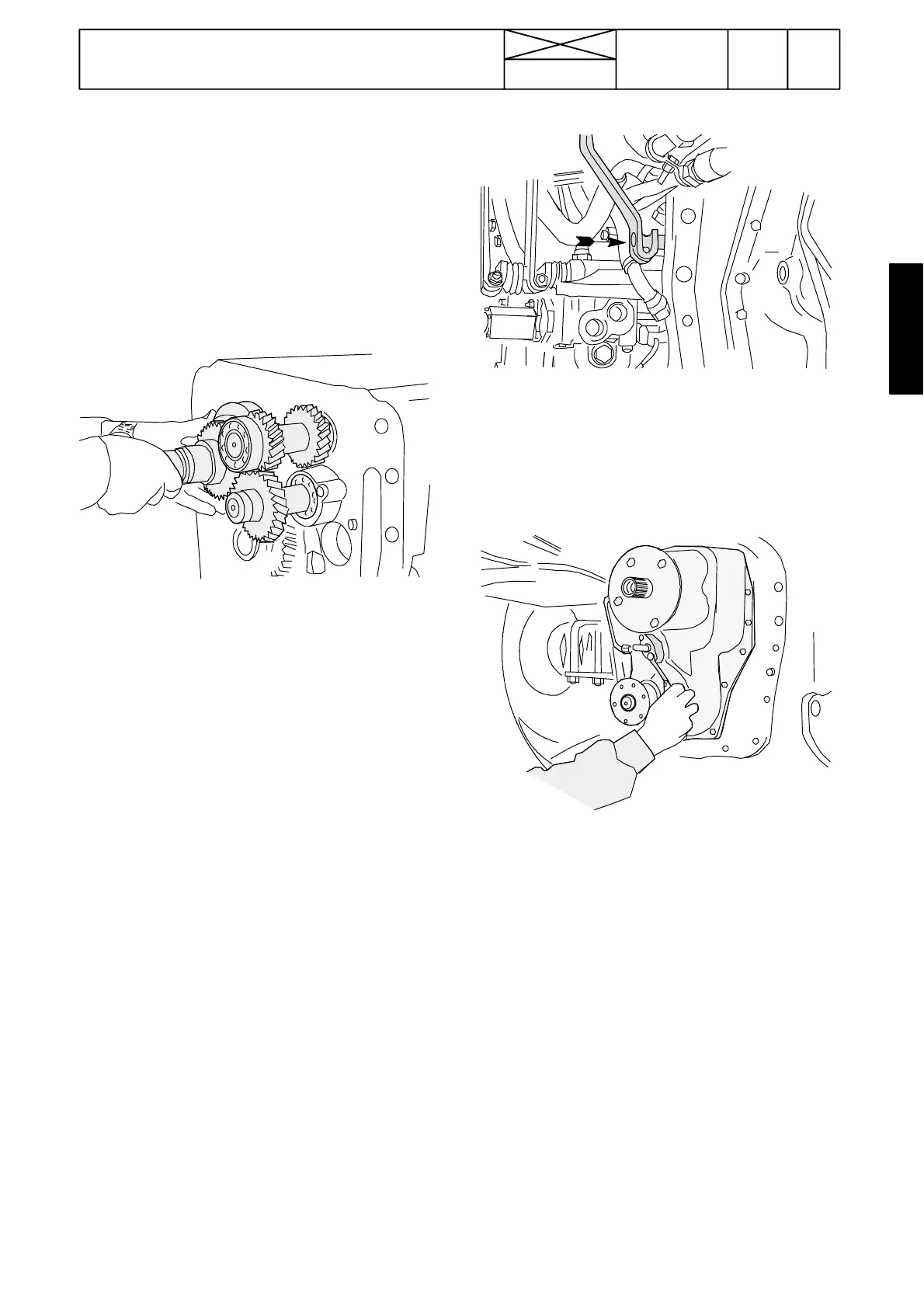

2. Fit the reverseshuttle shafts and the synchromesh unit onto

thegearboxfrontside(seefigureabove).

3. Place the selector fork together with sliding pieces (sliding

pieces can be fixed with universal grease on the fork during

mounting) onto thesliding couplerand guide the select or fork

rail through the hole on the gearbox front face. Fasten the fork

to the rail with a locking pin. With effect from tractor ser. no.

661937 the selector fork and the sliding pieces have been

modified. Fit the latest parts onto the reverse shuttle despite

the condition of the earlier part. See also page 421/ 2.

Note! Fit the reverse shuttle input shaft roller bearing into its

location on the housing. The foremost ball bearing is fitted

after the housing is in place against the gearbox front side.

4. Make sure that the 4WD output shaft nut has been fully tigh-

tened and then unscrewed one turn (2---step quick---shift

gear) or one and a half turn (Delta Po wershift) . Check that

the lugs on the 4WD multi---disc clutch pack are accurately in

line with each other.

5. Apply sealing compound to the contact surface between

the gearbox and the reverse shuttle housing.

6. Push the housing into place and turn the 4WD clutch so that

the lugs on the discs engage with the grooves on the clutch

drum.

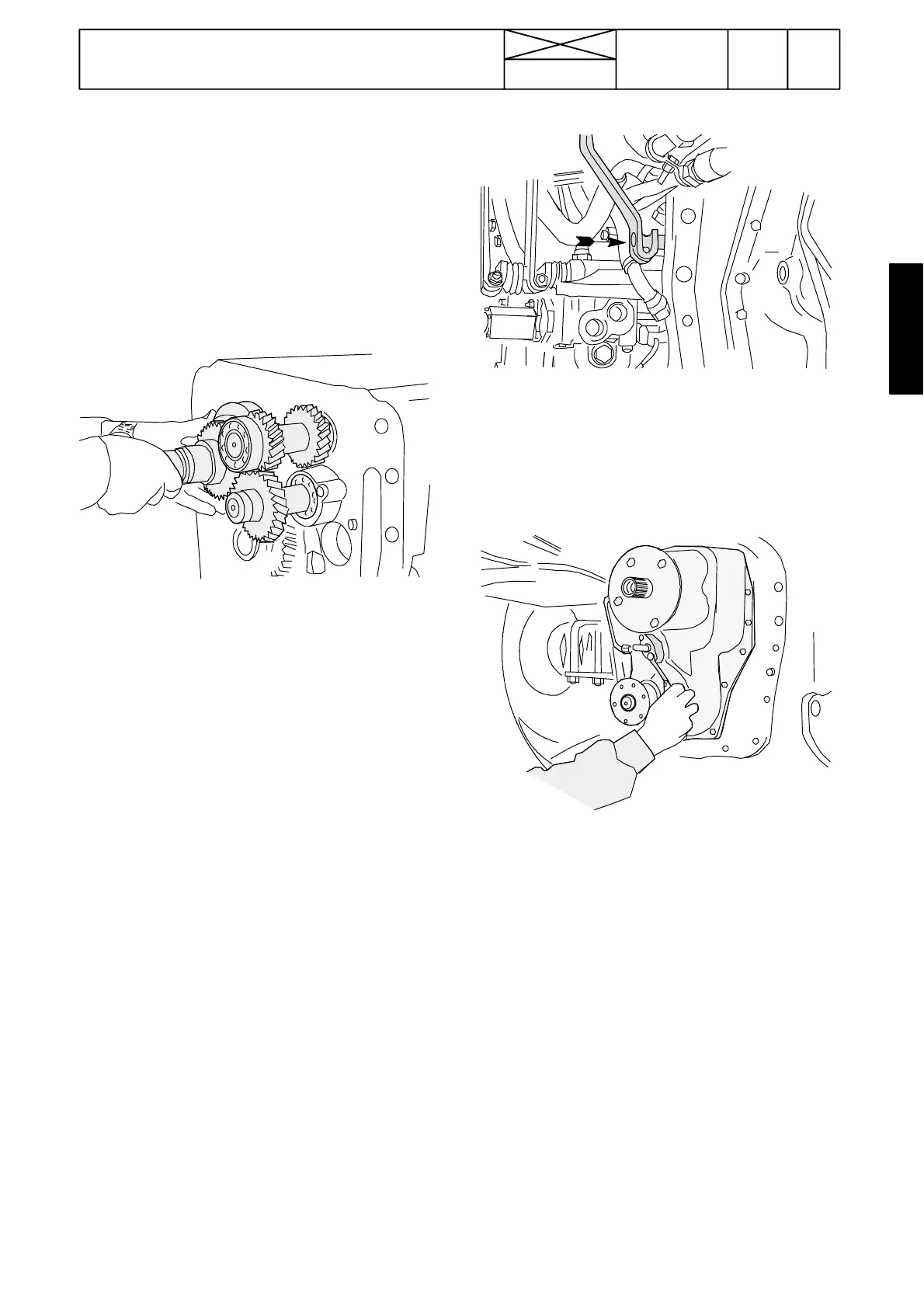

6. Push the housing against the gearbox front side and screw

four guide pins (M8, l= 100 mm) into the holes for housing

bolts.

7. Push the housing fully home (tap carefully with a copper

bar, but do not use too much force). Remove the guide pins

and tighten the reverse shuttle fixing bolts to 23 Nm.

Note! Ensure that the impulse disc is correctly in place

(E---models).

8. Fit the selecto r fork rail locking ball, spring and the plug.

Push the selector lever inwards and check that it has engaged

with the groove on the rail rear end.

9. Fit the input shaft ball bearing and its circlip. Fit the smaller

circlip onto the shaft.

10. Tr a c t o r s w i t h 2 --- s t e p q u i c k --- s h i f t g e a r o r w i t h o u t

quick---shift gear: Screw the long bolt into place under the

lubricating oil distributor piece and fit the distributor piece.

11. Connect the external pipes.

12. Attach the quick---shift gear to the reverse shuttle: 2---step

quick---shift gear, see instr. 4412A. 3 --- s te p qu ic k --- sh if t g ea r,

see instr. 444 1A points 19---26.

13.Assemblethetractorframe(seeinstr.4412Bor 423 5A).

Note! On AC IV models, fit the gearbox speed sensor B2C

onto the RH side of the shuttle housing, see page 351/3.

Loading...

Loading...