70

Model Code Page

21. Engine

1. 8. 2000

6000--8950

215 2

1. 6. 1999

C. Assembling and fitting lubricating oil

pump

1. Fit the gear wheels in the pump body. Fit the cover using

a new gasket. Partly tighten the bolts. Rotate the pump shaft

and tap the side of thecover lightly until the position isreached

where the shaft rotates most freely. Tighten the bolts and

check that the shaft still rotates freely.

2. Fit the key and drive gear onto the shaft (tapered joint with-

out key on the later pumps). Apply Loctite 242 onto the nut

threads and tighten the nut to 60 Nm. Remember the washer

under the nut.

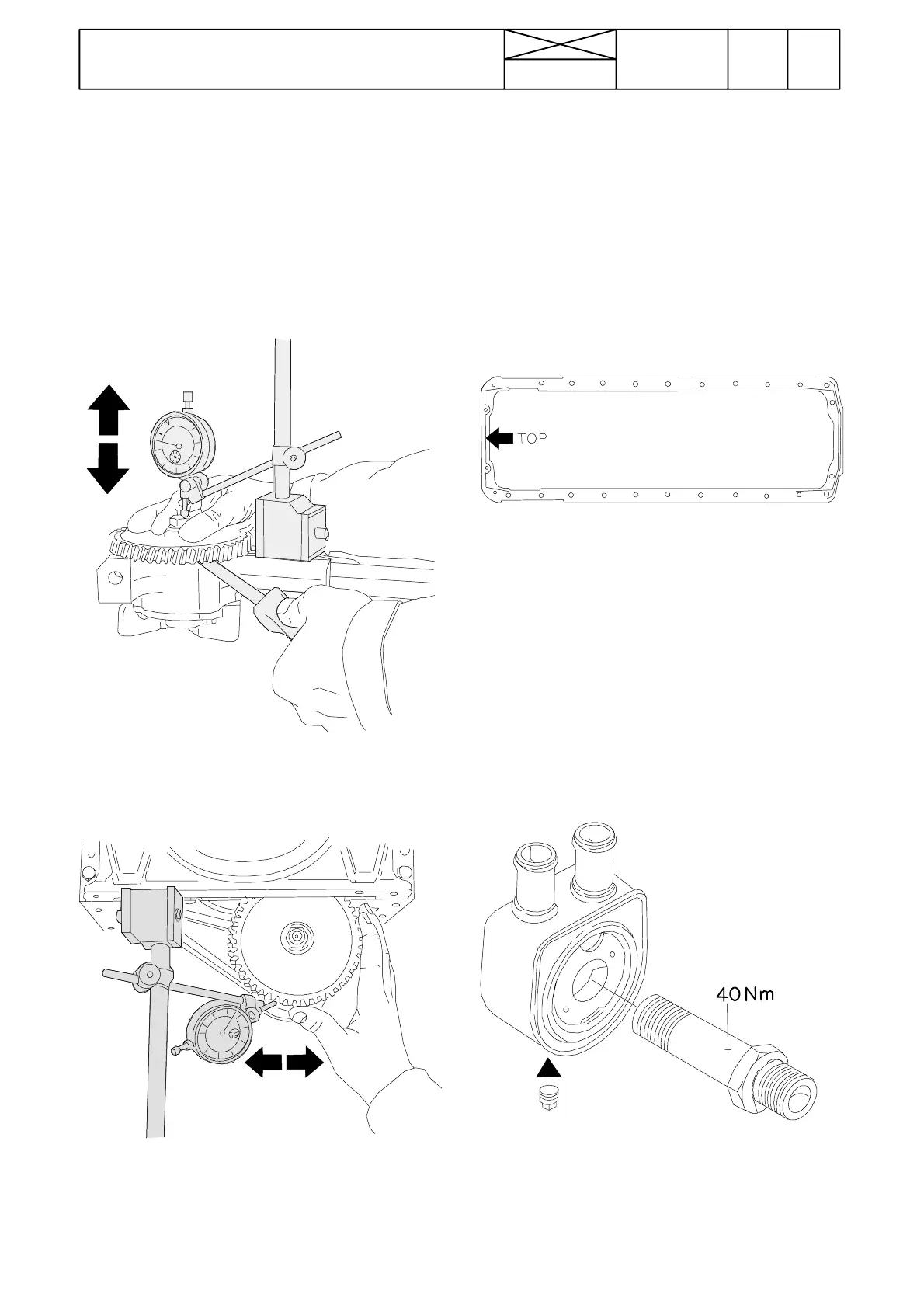

3. Fasten the oil pump in a vice and check the end float be-

tween gear and pump housing. The clearance which should

be 0,03 ---0,11 mm, is adjusted by the number of gaskets be-

tween the cover and body.

4. Fit the pump and check the tooth backlash against the

crankshaft gear. The clearance, which should be 0,05 ---0,25

mm, is adjusted with shims between the pump body and the

cylinder block (shims 0,2 mm, order no 8360 07871). One

shims increases/decreases the backlash about 0,07 mm.

Note! Whenmeasuring the too th backlash, the engine should

be the correct way up as the crankshaft bearing clearance af-

fects the tooth backlash.

5. Connect suction and pressure pipes toget her with new

seals.

6. Fit the engine (or the oil sump).

D. Fitting oil sump g asket

Fit the oi l sump gasket with silicone stripes against the cylin-

der block.

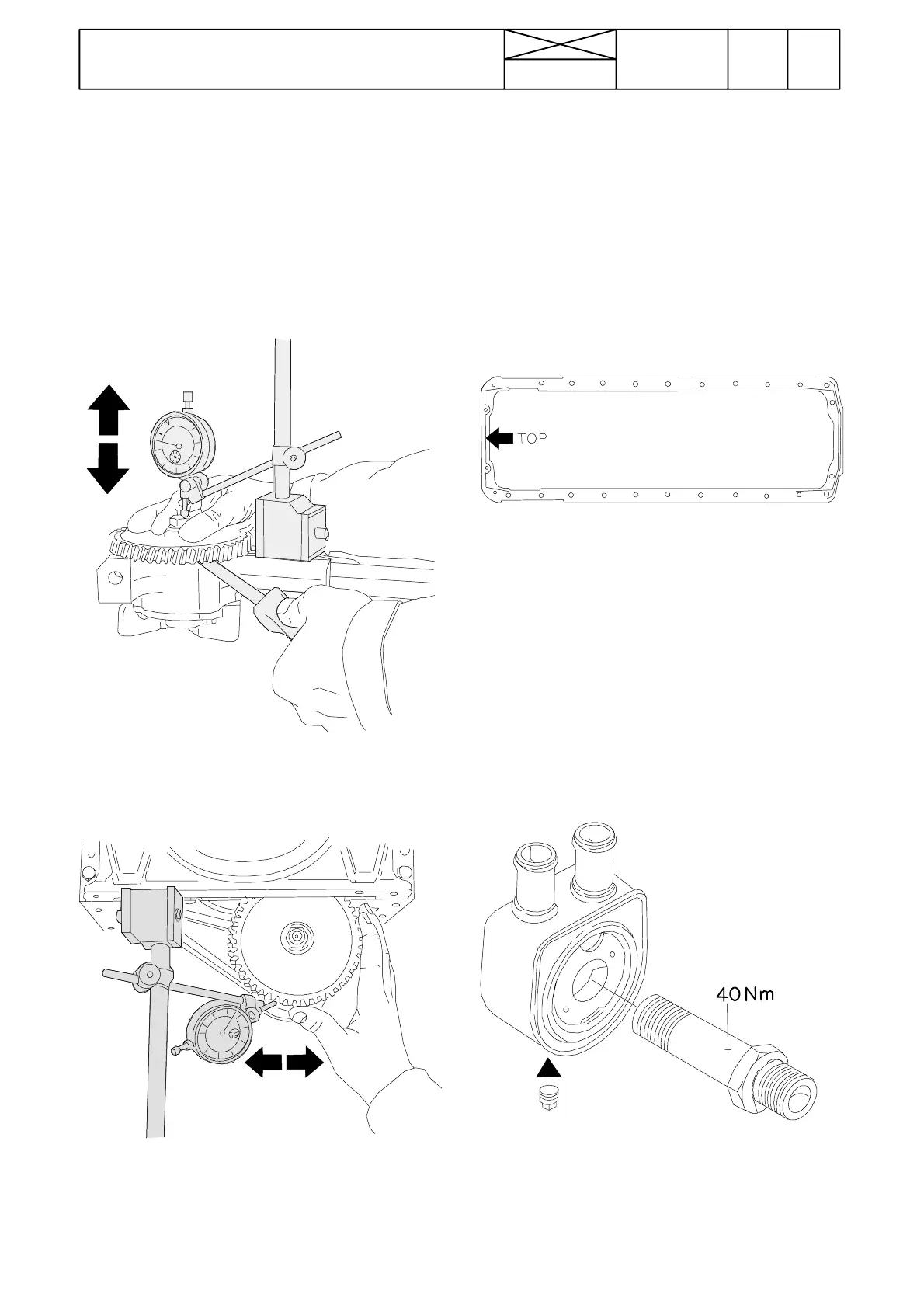

E. Lubricating oil cooler on 6800, 6850,

8400 and 8350---8950

The lubri cating oil cooler is placed in the oil filt er housing.

1. The engine coolant should be drained before removing the

lubricating oil cooler.

2. Fit new sealing rings. Fit the c o oler with draining plug tur-

ned downwards. Connect coolant pipes in the correct way.

3. Apply locking fluid to the nipple (the thread which attaches

to the filter head) and tighten it to a torque of 40 Nm.

Loading...

Loading...