PTO 1000/750 (540E)

D

0,7---0,9 mm

Loctite 572

The distance between the sensor end

and the impulse surface must be at

least 0,7 mm (at least 1/2 turn), other-

wise the sensor can be damaged

mechanically.

258

Model Code Page

31. Σ --- p o w e r s y s t e m

1. 10. 1999

8750, 8950 313 4

1. 6. 1999

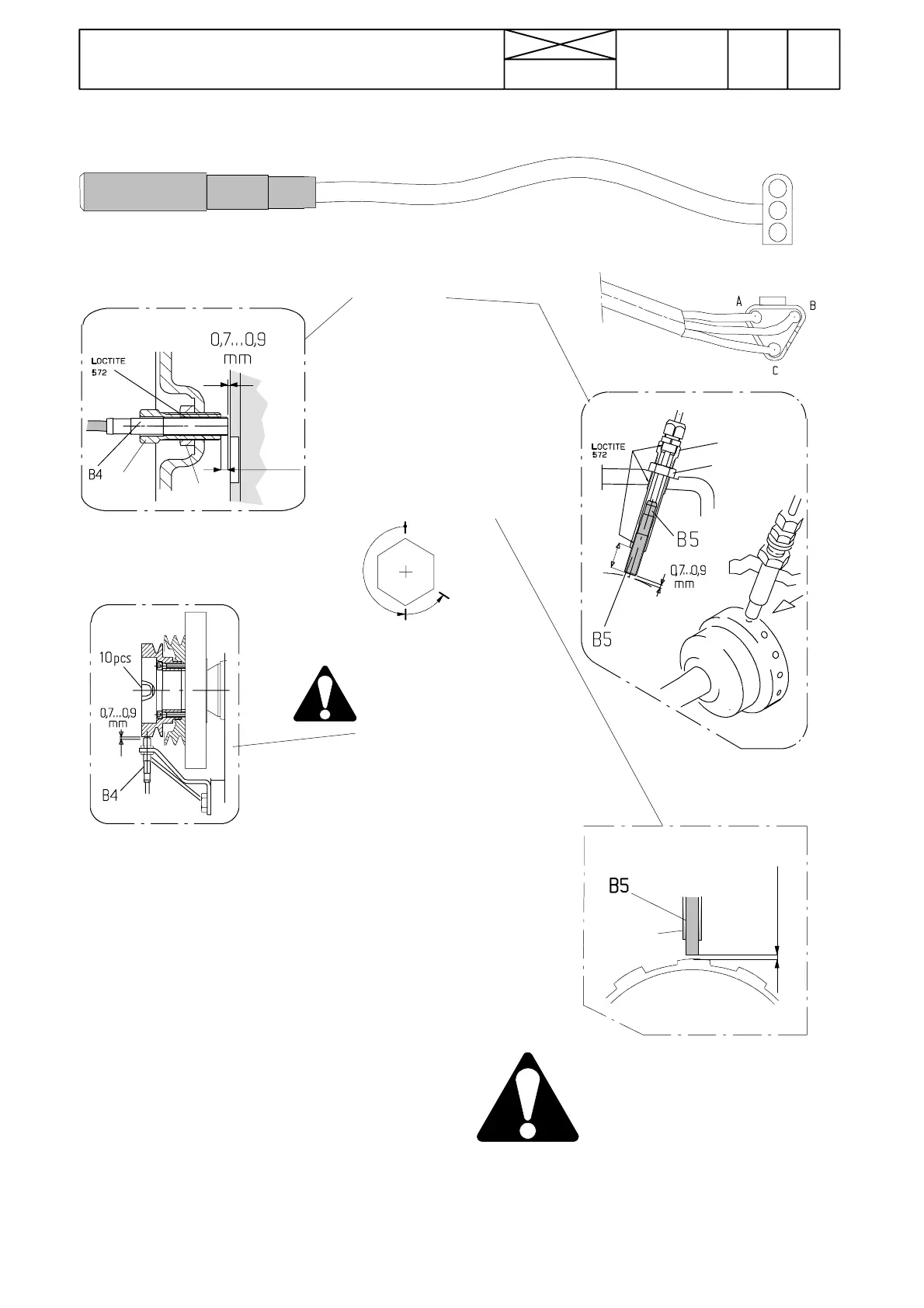

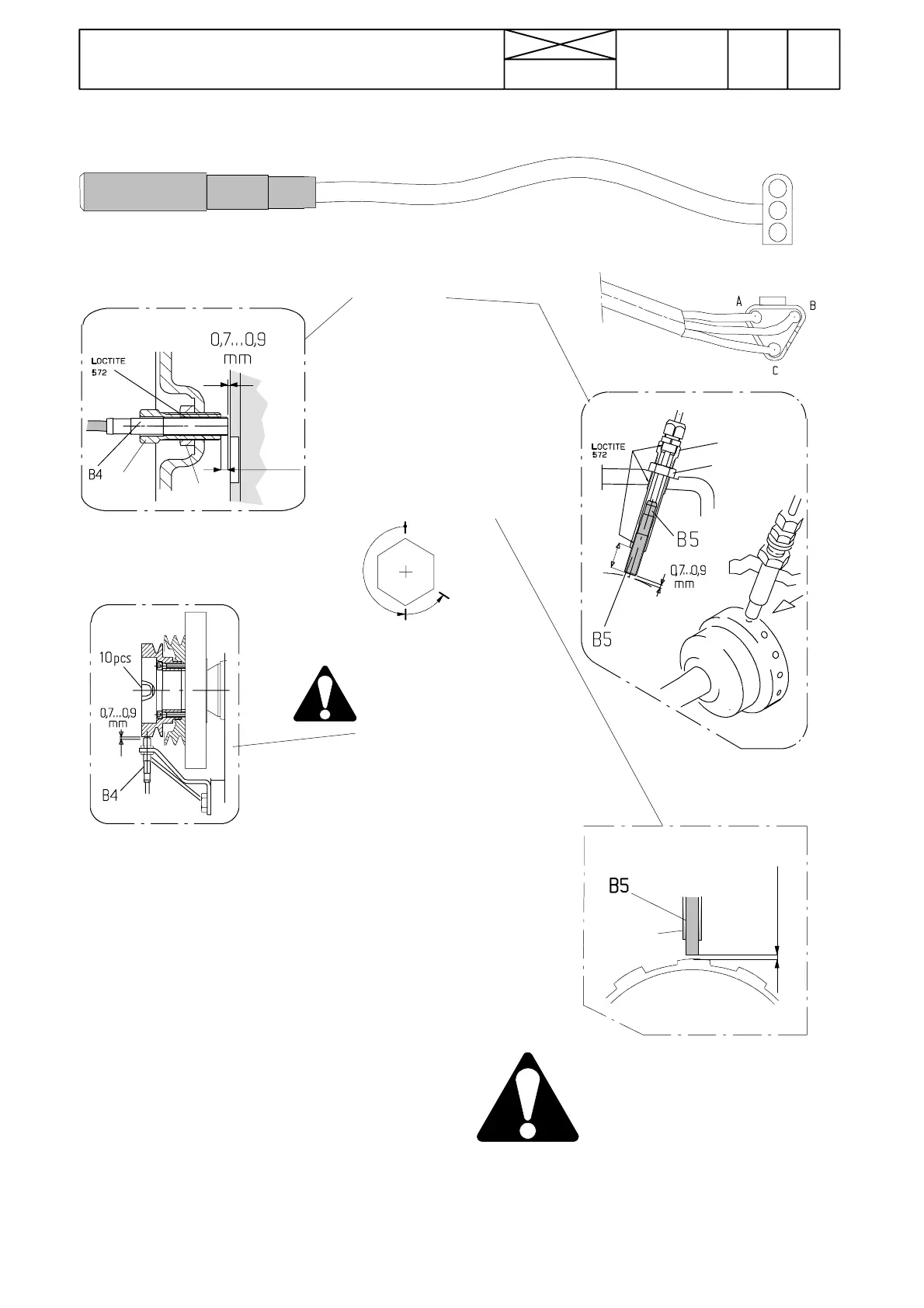

D. Sensors B4 and B5, versions 1.0, 1.1 and 2.0

1

2

3

1=+12 V (Brown)=A

2= Earth (Green)=B

3=Sign (White)=C

1

2

25

---G22506

G22507---

B

A

C

1

2

3---7 mm

A, C and D

In connection with sensor

replacement, screw a new

sensor into the sleeve to the

same depth as was the

earlier sensor. Use Loctite

572 when fitting the sensor.

Turnthesleeve2,untilthe

sensor touches the measur-

ing wheel (not at the notch)

andthenopenthesleeve

1/2---2/3 of a turn.Lockthe

sensor with nut 1 (sleeve

thread M18x1,5).

B

Screw the sensor first fully home until

the sensor end touches the measuring

wheel (not at the notch) and open it

then 3/4 turn. Lock the sensor with a

locking nut (sensor thread is M12X1).

H02431---

---H02430

PTO 1000

Stoptheenginebefore

sensor adjustment.

min.

max.

distance

0,7 mm

distance

1,0 mm

8750

8750

Version 1.0

Versions 1.1 an 2.0

Note! On 8950Hi models the foremost sensor is placed

in front of the DPS and the sensor is adjusted so that the

distance between the sensor end and the impulse sleeve is

0,7 ---0.9 mm (not at a notch).

Note! Versions 1.0 and 1.1: The ETB---light indicates by

flashing, if the sensor signals are not OK (e.g. there is no

signal from one sensor), ETB---light is flashing in time 0,5

sec on and 0,5 sec off. This flashing indicates, that the sen-

sor is faulty or there are poor contacts in the connectors/

wires. Also wrong adjustment can cause malfunctions.

IMPORTANT! Versions 2.0 and 3.0: Iftheenginespeed

sensor is damaged, the ETB---light flashes in above men-

tioned time twice, after which there is a pause of 1,5 sec. If

the PTO sensor is faulty, the ETB---light flashes three times,

after which there is a pause of 1,5 sec.

Loading...

Loading...