474

Model Code Page

37. Autocontrol 5 / 5.2

1. 8. 2000

370 16

6250--8950

1. 10. 1999

D. Checking pressures in shuttle

clutches in AC 5 and 5.2

See also the setting orders in instr. 370---24D.

Note! If the shuttle has malfunctions or if the shuttle has

been repaired or the proportional valves have been

changed, the function of the control system must be

checked. These tests ensure, that the pressure in the tractor

low pressure circuit is high enough and that the F/R propor-

tional valves are functioning.

Note! Ensure that the transmission oil temperature is

between +30˚C...+60˚C before work.

31965400

33743900

1. Measure pressure in the tractor low pressure circuit ac-

cording to instr. 911.

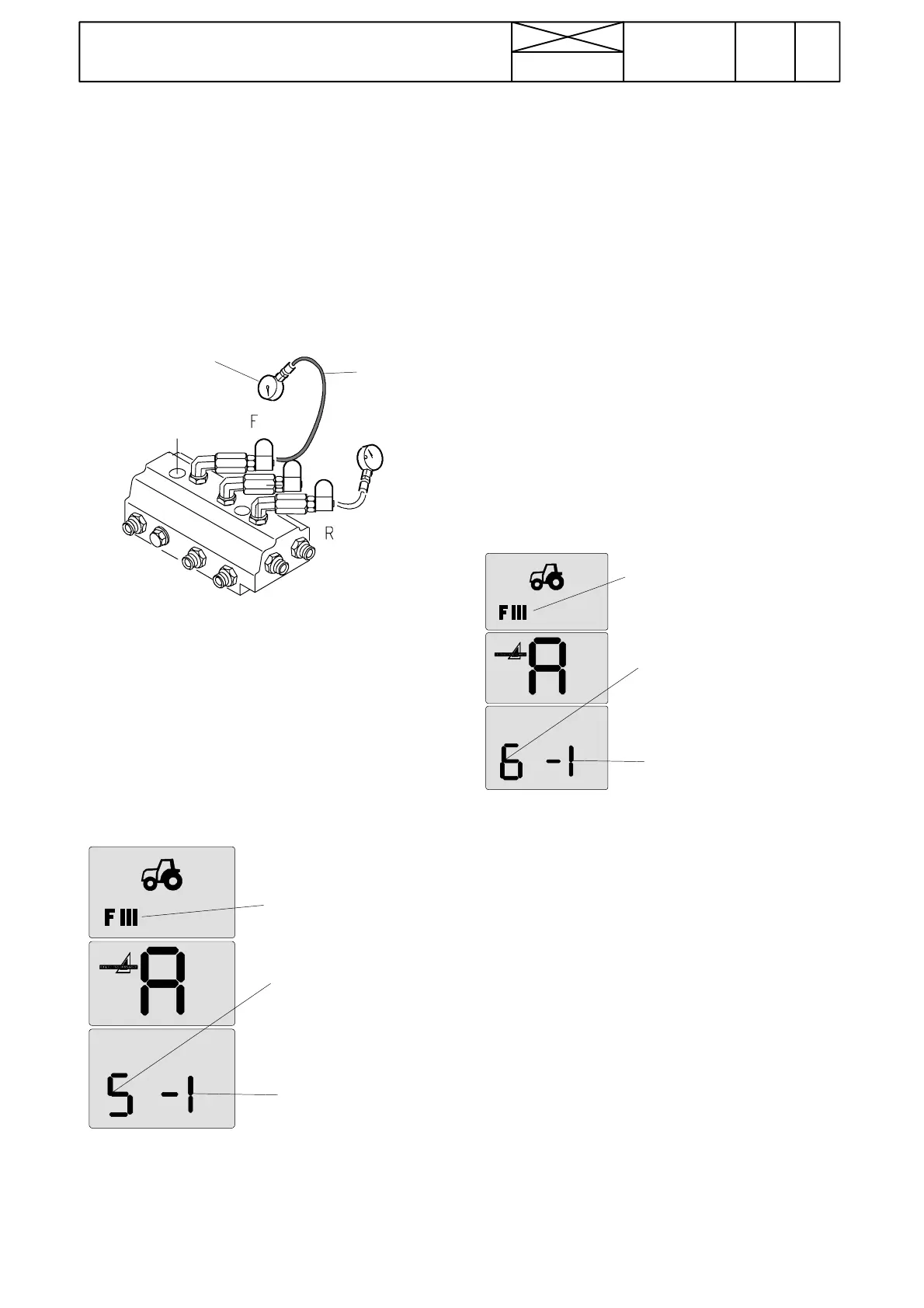

2. Connect a pressure gauge of 25 bar onto the F --- d i r e c -

tion pressure---test point (second point from the right, see

also picture on page 440/25).

3. Activate the setting mode according to instr. A on page

370/14.

4. Step with the DPS push buttons (in the speed gear lever

knob) and select point 5 in the setting mode menu (see

page 370/14 (AC 5) or page 371/10 (AC 5.2)) (F---clutch

initial pressure calibration) (blinking).

Initial pres-

sure calibra-

ting mode of

F---clutch

Index digit

FIII=setting

mode sym-

bol

5. Press the DPS pre---programming button, at which time

certain initial pressure index (between ---9...+9) starts to

blink in the three RH side segments.

Note! The factory setting of the index is normally --- 3...+3.

6. Press again the pre---programming button, at which time

the index digit stops blinking and read off the pressure

gauge reading, which should be 1,8---2,8 bar (AC 5) or

about 3, 5 bar (AC 5.2).

Note! The pressure value can be read after about ten sec-

onds, during which the pressure becomes even (in the

beginning possible pressure peak is not observed).

7. If the measured pressure value is different, change the

index. This is carried out so that after the pressure

measurement the blinking (5) is activated again with the

DPS pre---selection button, and the blinking index digit is

changed by stepping with the DPS push buttons.

8. After the index has been changed, press again the DPS

pre---selection button and read off again the pressure

gauge reading.

Note! If the pressure is too low, increase the index one step

at a time and vice versa and check the pressure again. If

the index is smaller than --- 4 or greater than +4,thefol-

lowing points must be checked:

--- Low pressure circuit of the tractor (instr. 911---1)

--- Condition of the valve coil, see page 370/13.

--- Cleanliness of the valve

--- Valve seals. Change the valve if necessary.

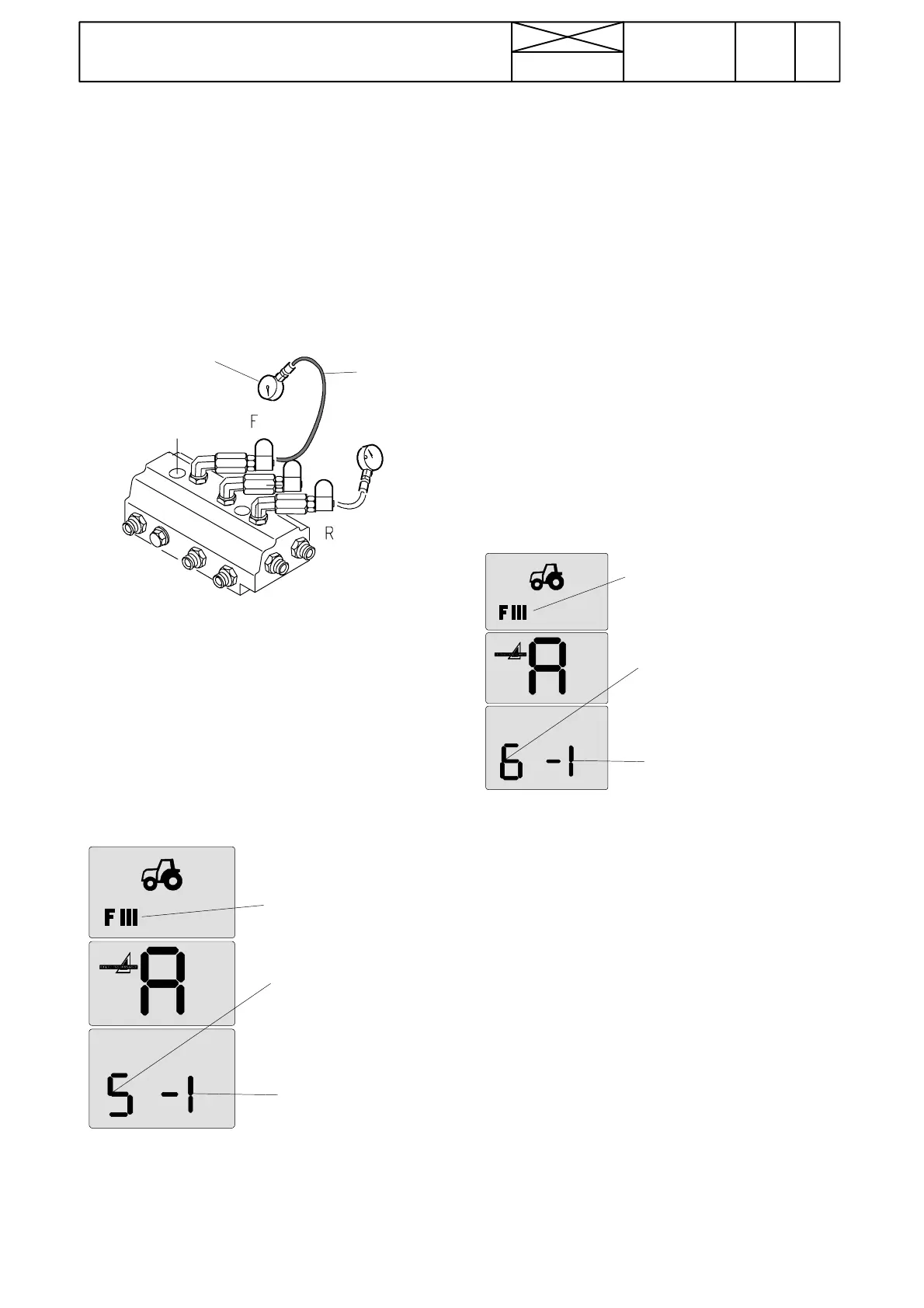

initial

pressure

calibrating

mode of

R---clutch

Index digit

FIII=set-

ting mode

symbol

9. Repeate the same also with the R---direction pressure---

test point (the LH side test---point on the valve block). In this

case the function number 6 of the setting mode menu

must be activated (R ---clutch initial pressure calibration).

10. Escape from the setting mode by switching off current.

11. Engage a mechanical gear and range gear lever in the

neutral. Start the engine and engage the forward---driving

direction (F). See the pressure rise of the F---clutch in the

pressure gauge. The pressure must stay in level, which is

max. 0,05 MPa (0,5 bar) below the pressure in the low pres-

sure circuit. e.g. 18,0 bar ---> 17,5 bar (measured in point

1). If the pressure is lower, it is possible that there is a leak-

age in the system (e.g. o---ring damaged).

12. Measure the reverse---drive direction (R) in the same

way.

13. Check the DPS---pressures in the same way (instr. 3E).

14. Set the indexes according to instr. 370/24D.

15. Test---run the tractor according to instr. on page

370/24E.

Loading...

Loading...