X13

V1, V4

1

4

7

3

6

9

2

5

8

481

Model Code Page

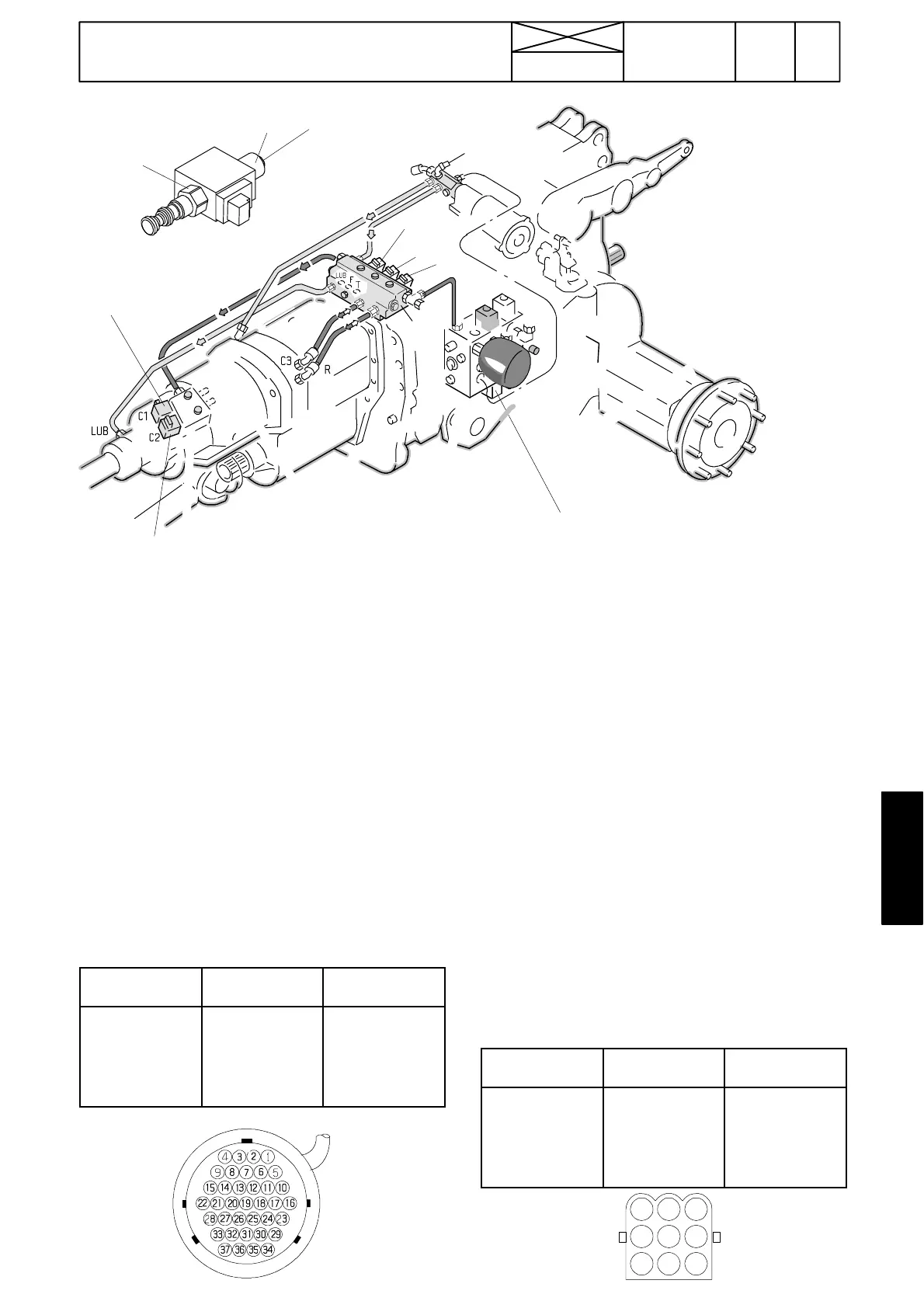

37. Autocontrol 5 / 5.2

1. 8. 2000

370 21

6250--8950

1. 10. 1999

P2 (Y6)

P1 (Y4)

P3 (Y17)

P4 (Y11)

P5 (Y12)

P6 (Y2)

5Nm

20 Nm

Note! Before removing valve

Y2 (P6), the temperature

switch S17 must be removed

(beside the valve).

Note! The end

of the spool

must be near

flushwiththe

valve body

C. Proportional valves, AC 5 and 5.2

Note! The unit self ---diagnostics show a fault code, if one of

the proportional valves is faulty, see table on page 370/6

(AC 5) or page 371/5 (AC 5.2) (PTO proportional valve is

not diagnosed in AC 5). After this the valve can be tested in

the test mode. FII, see table d on page 370/13.

1. All six proportional valves are similar:

--- P1=DPS foremost clutch C1 prop. valve Y4

--- P2=DPS middle clutch C2 prop. valve Y6

--- P3=DPS rearmost clutch C3 prop. valve Y17

--- P4=forward drive (F) proportional valve Y11

--- P5=reverse dirve (R) proportional valve Y12

--- P6=PTO proportional valve (not diagnosted in AC 5) Y2

2. When the proportional valve is energised, it is magnetic

and clutch in question is pressurised.

--- P1 is energised,when DPS speeds I or II are selected

--- P2 is energised, when DPS speeds I or III are selected

--- P3 is energised, when DPS speeds II or III are selected

--- P4 is energised when forward drive is engaged

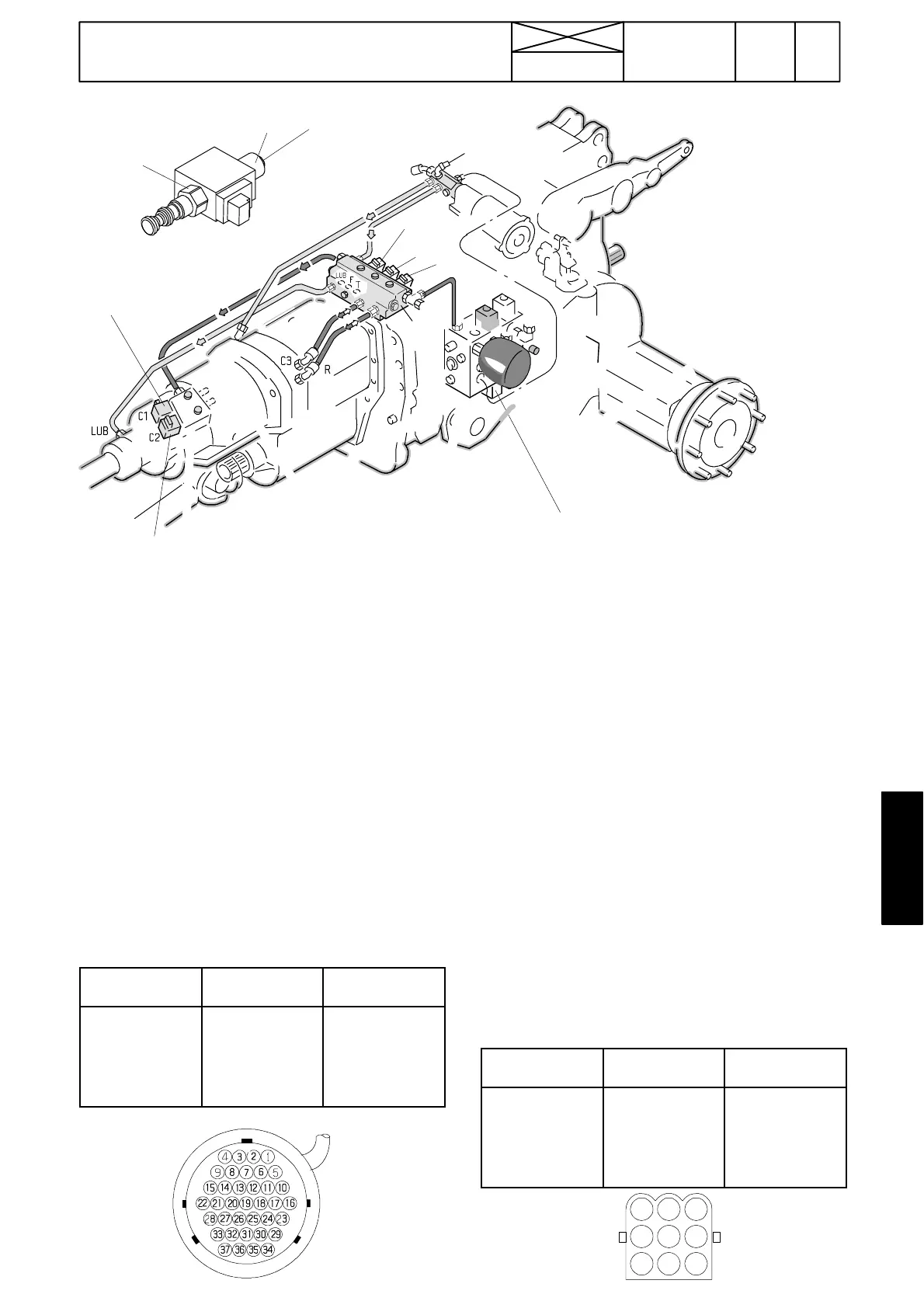

PINS (X13)

SOLENOID RESISTANCE

(+10...+30 ˚C)

2<>5

4<>5

7<>5

11<>5

12<>5

13<>5

Y2 (PTO)

Y4 (C1)

Y6 (C2)

Y17 (C3)

Y11 (F)

Y12 (R)

7 --- 9 o h m s

--- P5 is energised when reverse drive is engaged

--- P6 is energised when the PTO is engaged.

3. The resistance of the proportional valves is measured

from connector X13 pins. Correct value is 7 --- 9 o h m s

(+10˚ C...+30˚C).

4. If the resistance is incorrect, the valve solenoid is

changed. After this the valve indexes must be set, see instr.

on page 370/24D.

5. If the resistance is correct, but in the circuit there are mal-

functions, check the valve wires and connectos. If these are

OK, perform the calibration of the initial pressure. Also the

diodes must be checked in AC 5 according to table below

(in AC 5.2 the diodes are placed in the control unit A1).

Note! Onepossibleandcommonfaultisimpuritiesinthe

valves. This can cause faults which are very difficult to find.

If you doubt this fault, change the proportional valve or try

to clean it.

6. If the valve and its wires seem to be OK, but malfunc-

tions exist, the fault can lie in the control unit.

Note! During repair check (before engine start) that the

valve spool end is nearly flush with the valve body.

Diode test with multimeter, AC 5 only.

SOLENOID

DIODE HOU-

SING (V1, V4)

PINS (V1, V4)

Y2

Y4

Y6

Y17

Y11

Y12

V1

V1

V1

V4

V4

V4

2<>5

9<>8

7<>8

9<>8

7<>8

3<>6

Loading...

Loading...