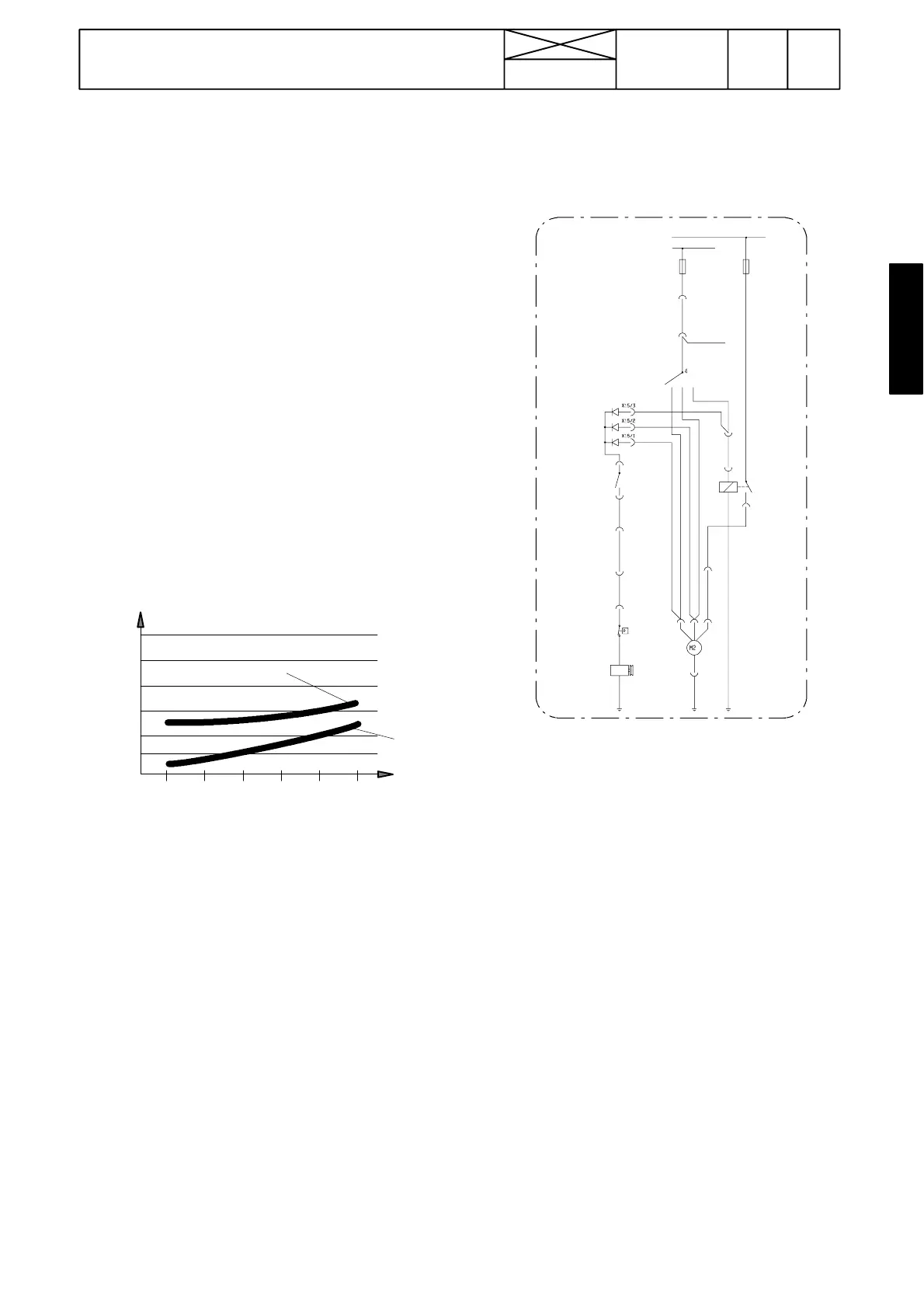

Outdoor temperature ˚C

Nozzle temperatures ˚C

1145

Model Code Page

83. Air conditioner

1. 1. 1994

6000--8750 831 3

15. 5. 1993

1. Fault tracing without special

equipment

Note! This instruction supposes that the outdoor temperature

is high enough so that the temperature switch switches on the

compressor.

A. Correct function

When the air conditioner is functioning properly the com-

pressor runs and stops at regular intervals and cool air flows

into the cab according to the position of the temperature

switch.

To check for malfunction, carry out the following simple test in

the shadow by fitting a thermometer sensorinto the frontven-

tilation nozzle on the LH side and by following nozzle tem-

peraturesduring 5---10 minutes. During thistest the windows,

doors and re---circulation nozzles should be closed. Select

the max speed for the fan. Adjust the max cooling effect and

set the engine revs to 1500 RPM.

Nozzle temperatures should be according to the curves

below (±1,0˚C). Curve A is for the earlier air conditioner and

curve B for the later air conditio ner which has the roof console

on the RH side of the roof:

20 22 24 26 28

12

14

16

18

20

30

10

A

B

If measured temperatures agree with the curve above, the air

conditioner is in order.

If the nozzle temperatures are higher, make sure that the

heater contro l knob is closed so that the warm engine coolant

does not circulate in the heating element which is placed in

front of the evaporator. If the knob is closed, see the following

instruction B .

B. Refrigerant filling and moisture

--- Check the amountof refrigerant and moisture in the system

through the drier inspection gl asses (see page 831/2).

Moisture in the system causes icing in the expansion valve

and in the compressor which in turn causes malfunctions.

Refrigerant+water causes a corrosive compound.

P ossible leakages can be found with an electronic leak

detector. If the refrigerant filling is wrong or there is moisture

in the system, contact an expert who knows refrigerating sys-

tems. If everything is OK, see the following instruction C.

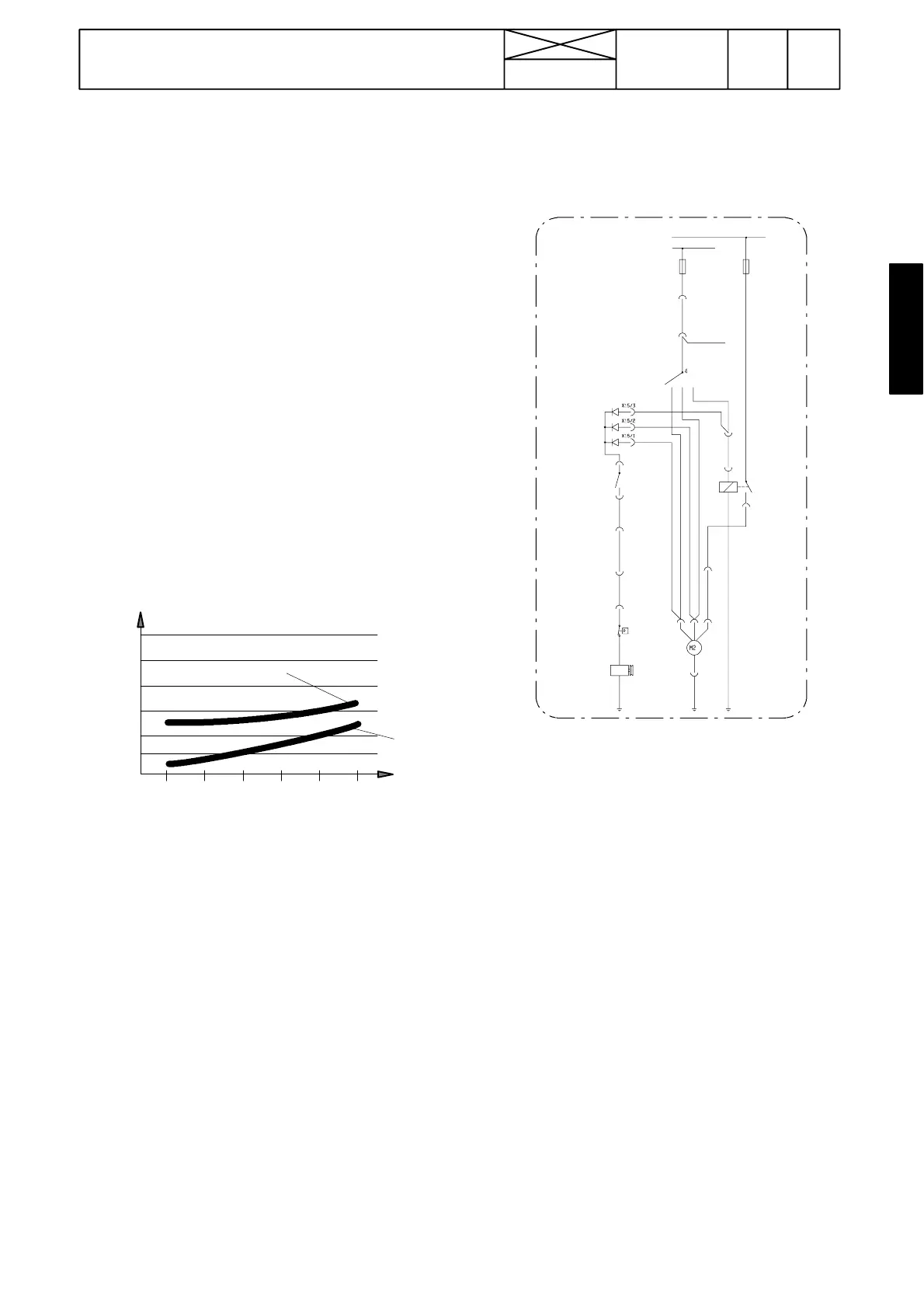

C. Electric system

S3

K6

S8

S19

Y5

M2

X15

234

1

1023

30

15

18KE

F21

F15

18KE

4VI

3RU

38LI

X5/1

38LI

X24/6

38LI

X24/4

18KE

X7/3

70MU

X7/1

X24/5

70MU

X11/9

X19/8

93MU

93MU93MU

2

1

Switch on current to the tractor and turn on the fan S3. If the

fan does not start, check fuse F21. If the fan started, turn the

temperature switch S8 to max cooling effect at which time the

click---sound must be heard from the compressor magnetic

clutch. This indicates that the electric system functio ns.

If the click---sound was not heard, disconnect the wires to the

pressure switch S19 and connect the wire ends (never con-

nect the + wire to the frame). If the click can now be heard in

the compressor, the electric system is OK, but the fault lies in

the pressure switch or in the system pressures. Call an expert.

If the click---sound cannot be heard when connecting the

pressure switch wires, check the supply wire for current to the

pressure switch. If it is there , the fault lies in the compressor

magnetic clutch or in its wiring.

Measure the voltage from the pressure switch supply wire

with different fan speeds. If there is no current with some fan

speed, the fault lies in diodes, which should be changed. The

diodes cannot be changed separately but the complete wir-

ing set no 326 107 00 (earlier air conditioner) or no 328 351 00

(later air conditioner) sho uld be changed.

If there is no current to the pressure switch wire, check con-

nector X19/8 in the cab front wall on theRH side and alsocon-

nector X11/9 which is placed behind the roof panel in the cab

(on the RH side).

If there is no current to the pressure switch wire, connect the

temperature switch wire ends. If now there is current to the

pressure switch supply wire, the fault lies in the temperature

switch which should be changed.

Loading...

Loading...