831

Model Code Page

46. Power take ---off

8. 11. 1990

6000--8750 462 1

1. Reconditioning PTO (Op. no. 462)

Note! In the instruct ions below has been used a PTO unit

which is equipped with parts for ground speed PTO. The in-

structions are good also for PTO units without the ground

speed PTO.

A. Re moving PTO unit

1. Drain the oil from the transmission. On E---models, discon-

nect the PTO speed sensor wire. Remove the position sensor

of the hydraulic power lift.

2. Disco nnect the auxiliary hydraulic pipes from the quick---

action couplings (in front of the bracket for couplings).

3. Disconnect the PTO control cable, pick---up hitch release

control and the locking pin for the levelli ng screw control rod

joint.

4. Lower the towing hook. Disconnect the lifting links from the

lifting arms.

5. Disconnect the lifting cylinder upper ends from the lifting

arms. Disconnect the oil hoses from the lifting cylinder and

lower them.

Note! Support the lifting arms by pushing an iron bar through

the hole for lifting cylinder pin and further under the return oil

connec tion for auxiliary hydraulic (the cam on the lifting shaft

can damage if t he lifting arms can rotate freely).

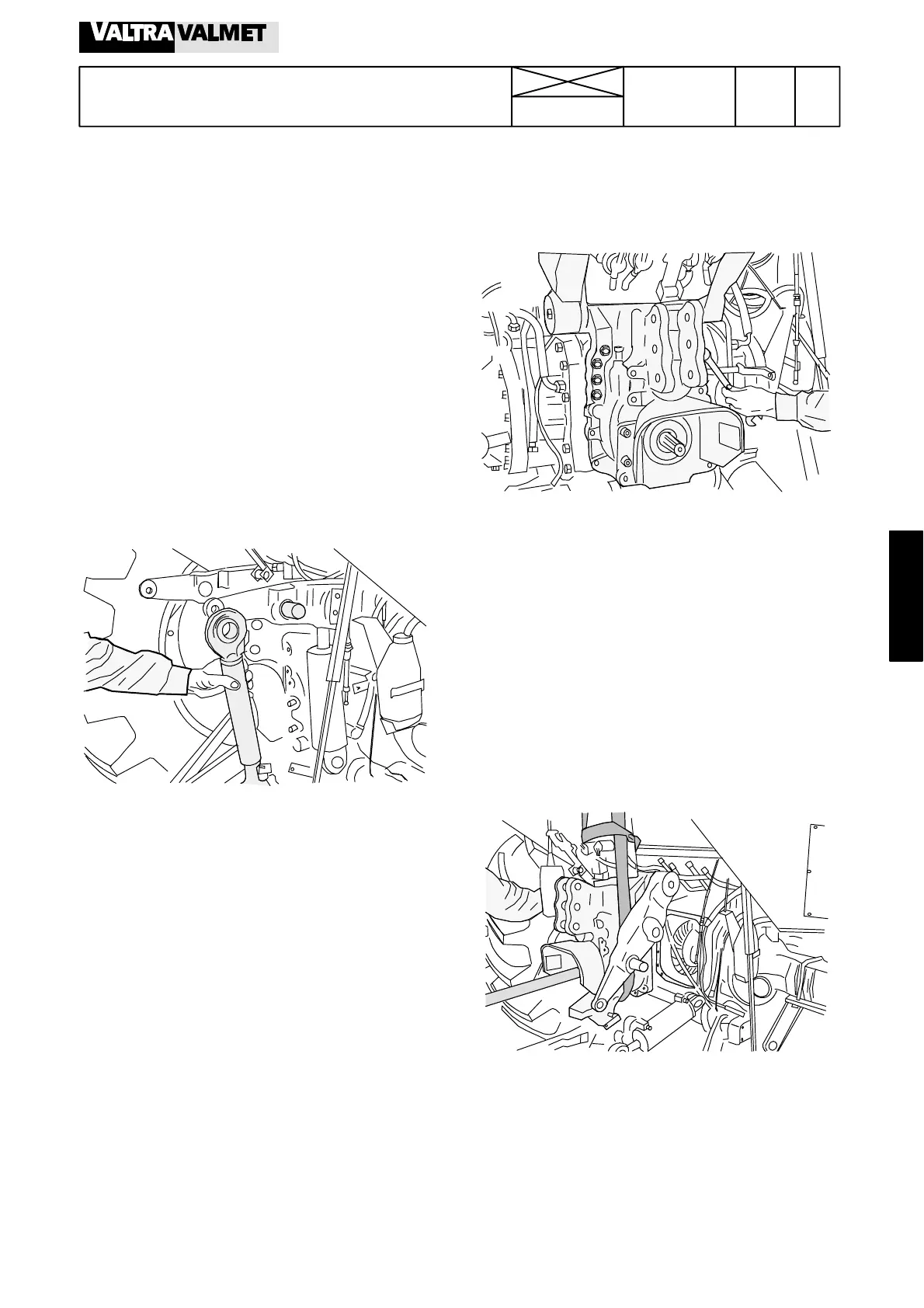

6. Unscrew the PTO housing fixing bolts. Disconnect the draft

sensor connectors. Open the leak oil reservoir cap and re-

lease its hoses.

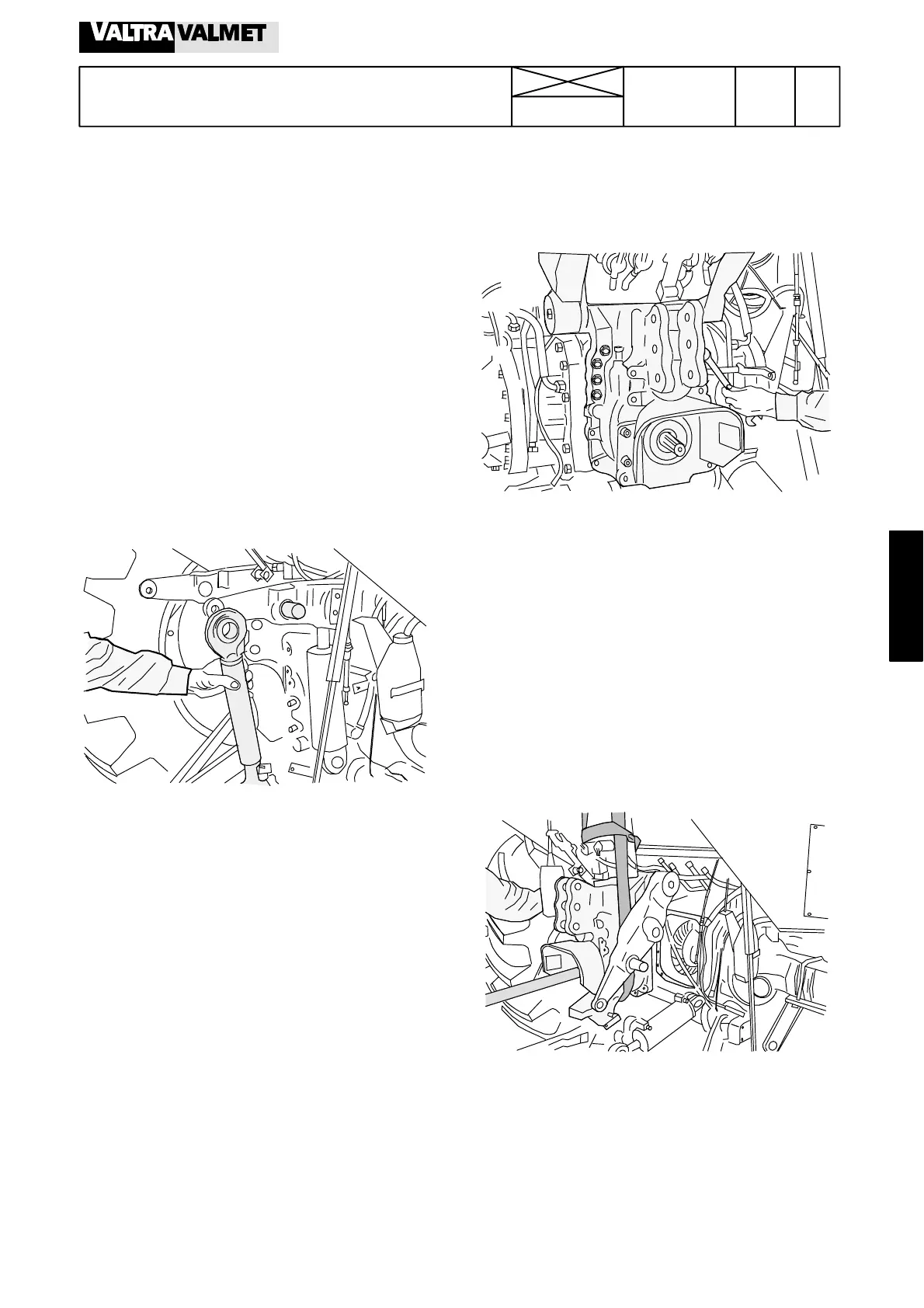

7. Wrap a lifting rope round the PTO housing. Push a tube

onto the PTO shaft end. The unit can be kept in balance with

the tube.

Note! As a suitable tube can be used tool ET 893 550 (tool for

Carraro front axle on V almet 05---series).

8. Raise the towing hook with a garage jack about 40 cm and

pull the PTO unit s traight out from pl ace.

Loading...

Loading...