379

Model Code Page

34. Autocontrol ---III

15. 6. 1992

6600E, 8100E 342 9

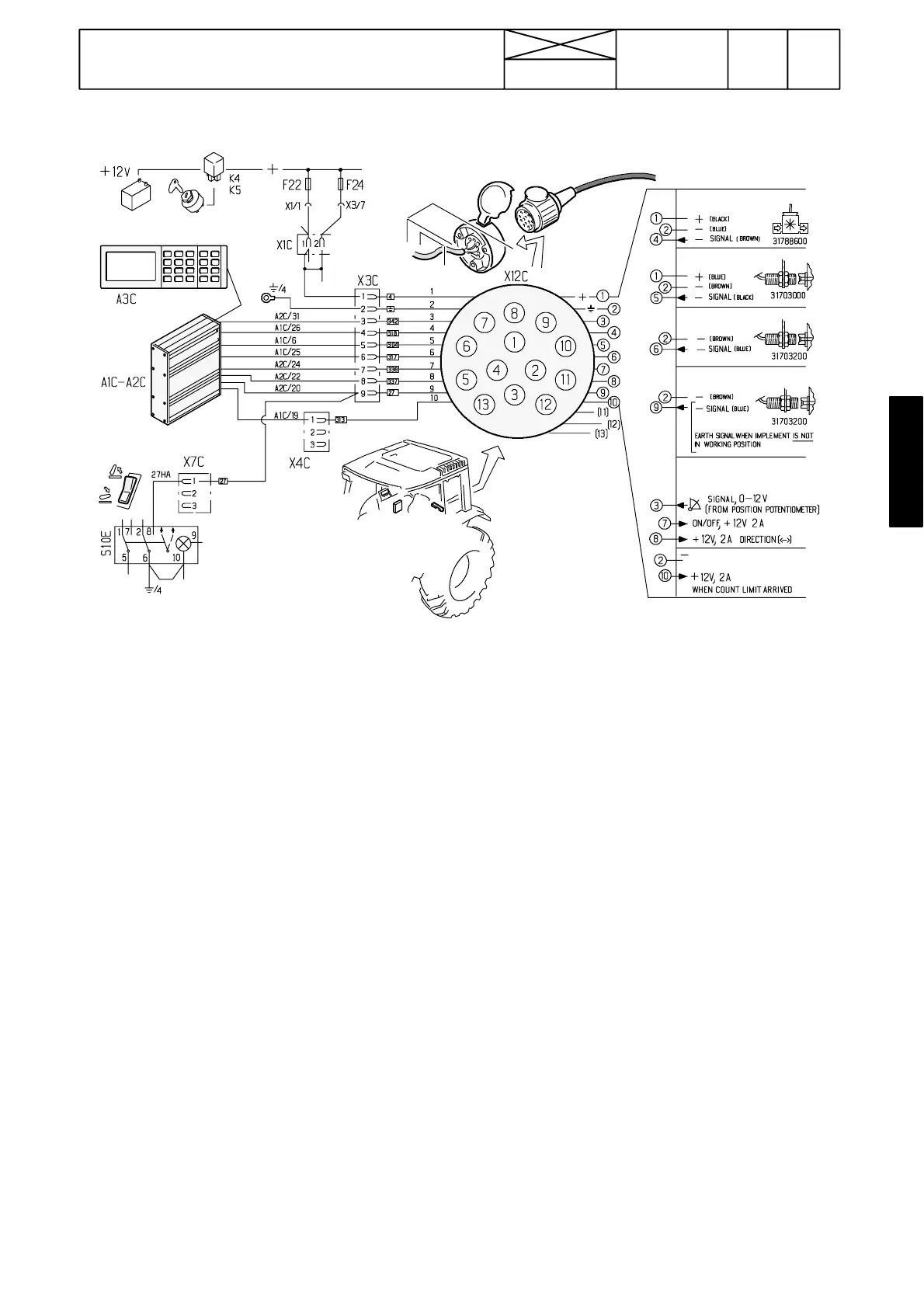

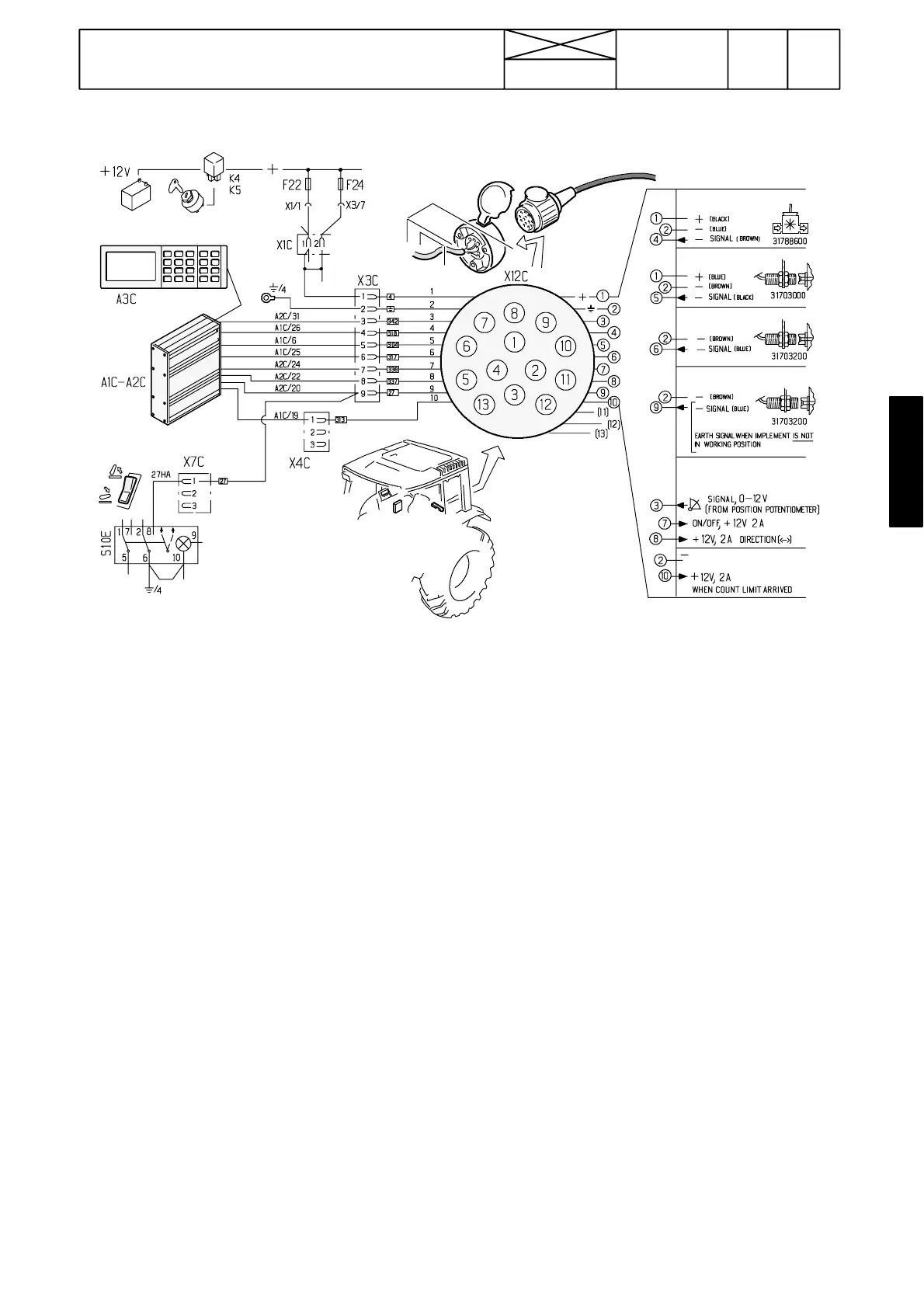

AC---III, implement socket

Implement sensors

Flow meter

RPM sensor

Piece counter

Working position

Signals for controlling

linear actuator

When the limit of count is reached

Checking line from implement socket to

A C --- I I I u n i t

--- Switch on current to the tractor

--- Measure the supply voltage between socket terminals 1

and 2 (= battery voltage, about 12 V DC).

--- Connect a microcomputer to the AC---III unit and activate

the trouble shooting chart (see page 341/1).

FREQUENCY INPUTS

1. Shunt between socket terminals 2 and 4 (break connec-

tion). A number signal must appear on the PC at point Flow.

This function is the same as the flow meter paddle wheel

would revolve. Also AC---III display shows some value in the

liquid amount mode (litres).

2. Shunt between socket terminals 2 and 5 (break connec-

tion). A number signal must appear on the PC at point RPM

impl. Also AC---III display shows some value in the implement

RPM mode. This function is the same as a magnet would

pass by the sensor.

3. Shunt between socket terminals 2 and 6. A number signal

must appear on the PC at point PCS every time the connec-

tion is broken off and on (summing counter). Also AC ---III dis-

play shows in the piece counter mode the same value. Note

possible limiting program, which limits the max number of

items. When the limit value is achieved a signal (0 changes

to 1) appears at the point Pieces counter (DIGITAL OUT-

PUTS). This signal can also be measured with a voltmeter

between socket terminals 2 and 10. This function is the same

as a magnet would pass by the sensor.

DIGITAL INPUTS

4. Activate the hydraulic power lift and turn the lift/lower switch

to the lowering position. Shunt between socket terminals

2and 9. A signal (1 changes to 0) appears on the PC at point

Implement pos. When the socket terminals are connected

the arrow on the AC---III display turns to point upwards. The

function is the same as a magnet would be opposite the sen-

sor. The lift/lower switch has the same function.

ANALOG INPUTS

5. Signal from possible position potentiometer: Shunt

between socket terminals 1 and 3, after which a number sig-

nal appears on the PC at the point Implement pot

. Here with

battery voltage the signal is about 250. Also AC---III display

shows some value (e.g. 100) in the implement position mode.

Signals to linear actuator

--- connect an adjustable resistor to the socket poles 1 (+:

black), 2 (---: Red) and 3 (sign: Yellow).

--- calibrate the resistor’s extreme positions (e.g. 0 (P1) and

100 (P2)).

--- input 5 pcs pre---programmed resistor positions (e.g. 10,

30, 50, 70 and 90)

--- move the resistor spindle inwards and outwards in the

middle range and check that the output signals appear on the

PC with e.g. the pre ---set position 50. Implement dir (current

to a relay for controlling actuator rotation direction; 0 or 1) and

Implement act (current to a relay for controlling actuator; 0

or 1) (both DIGITAL OUTPUTS)

By connecting a test lamp to the socket poles 7 or 8 (earth

from any frame contact) it can be checked if the current

actually comes to the socket.

N.B. If the line from the socket does not function, check con-

nectors X3C and X4C (in the lever console). Check also wire

connections in the socket. If the output signals do not come

the ECS is faulty.

Loading...

Loading...