257

Model Code Page

31. Σ --- p o w e r s y s t e m

1. 8. 2000

8750, 8950 313 3

1. 10. 1999

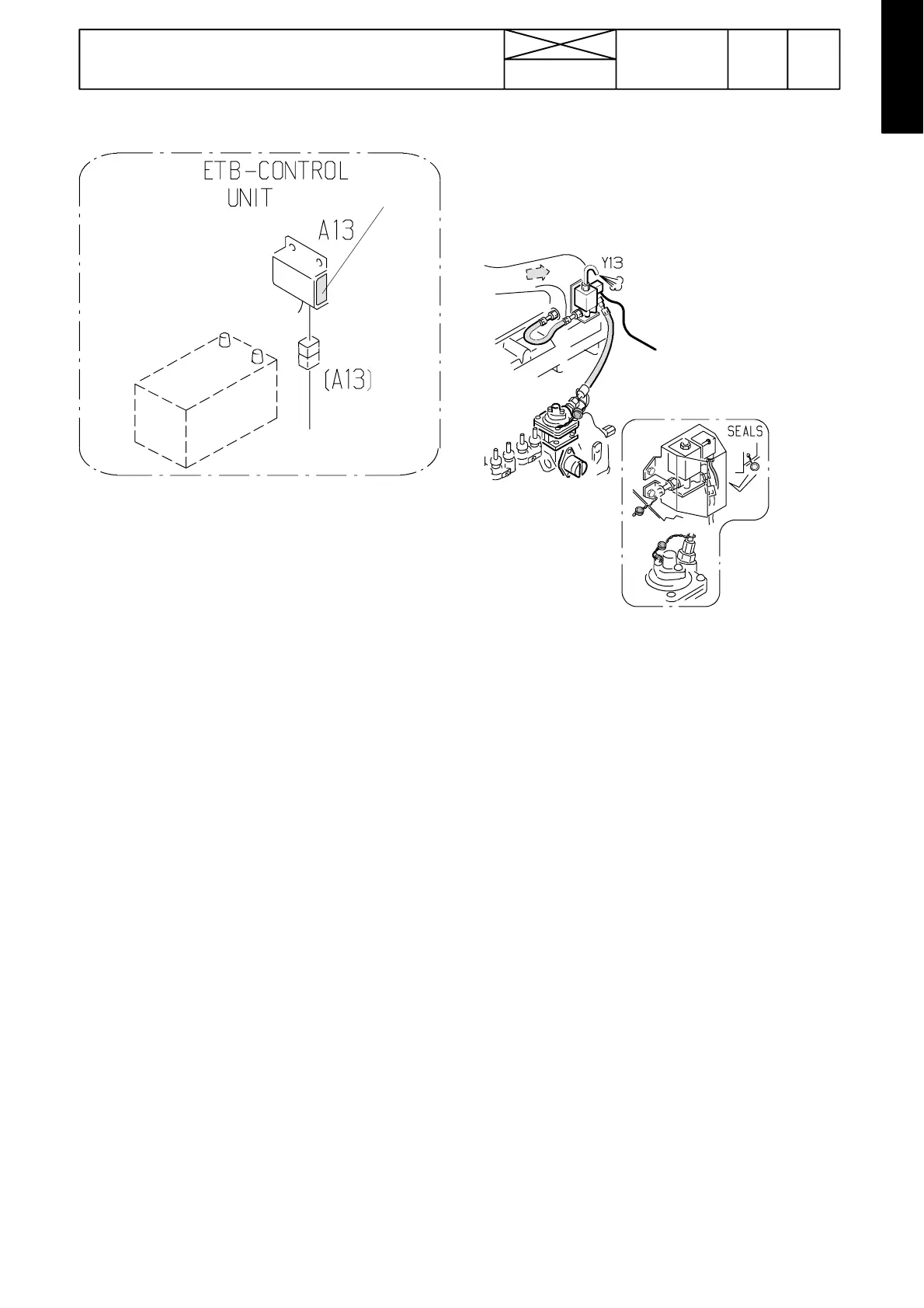

B. Control unit A13

Marking

dot

The control unit is situated in the engine compartment.

Function

The control unit gathers information from the sensors and

switches and sends required electric signals to the solenoid

valve and the pilot lights in order to switch on/off the higher

engine output range.

The torque of the PTO unit should be at least 2 sec. (0,5

sec. in versions 2.0 and 3.0) above the switch ---on torque,

before the higher output range is switched on. This elimin-

ates malfunctions caused by occasional torsional vibra-

tions, e.g. during starting. When the PTO unit torque

decreases, the torque should be at least 5 sec. below the

disengagingtorquebeforethelowerenginetorquerangeis

switched on. Thus e.g. a sudden loading decrease in the

PTO unit (e.g. at occasional holes or puddles etc.) does

not disengage the higher output range. In addition, the dis-

engaging torque is a little lower than the engaging torque.

These differences in the times and torques also prevent

possible seesawing engagements.

Note! The engaging torque has been changed, see table

on page 313/2A.

If the ETB light does not light or flash, although the PTO is

loaded so that the higher output range should engage and

the digital instrument does not show the percentage value

of the PTO output (e.g. the instrument shows 99 Ac or 0 Ac

regardless of the loading of the PTO unit), this indicates that

the system has been damaged, see fault tracing on pages

313/6---13.

If there are malfunctions in engagements between the two

output ranges (e.g ETB---light blinking), the control unit may

be damaged or the sensors have faulty adjustments.

Spare part control units have been programmed in the fac-

tory and they can be fitted in place of the damaged units

(connectors are supplied with the unit). If the control unit

A13 has to be changed, the solenoid valve seal must be

broken.

IMPORTANT! If on 8750 tractor is fitted the control unit of

version 2.0 in place of the versions’ 1.0 or 1.1 units, con-

nector A13 wires to pins 4, 7 and 12 (on tractor wire loom

side) must be disconnected and the ends of the wires must

be isolated (if not made earlier)

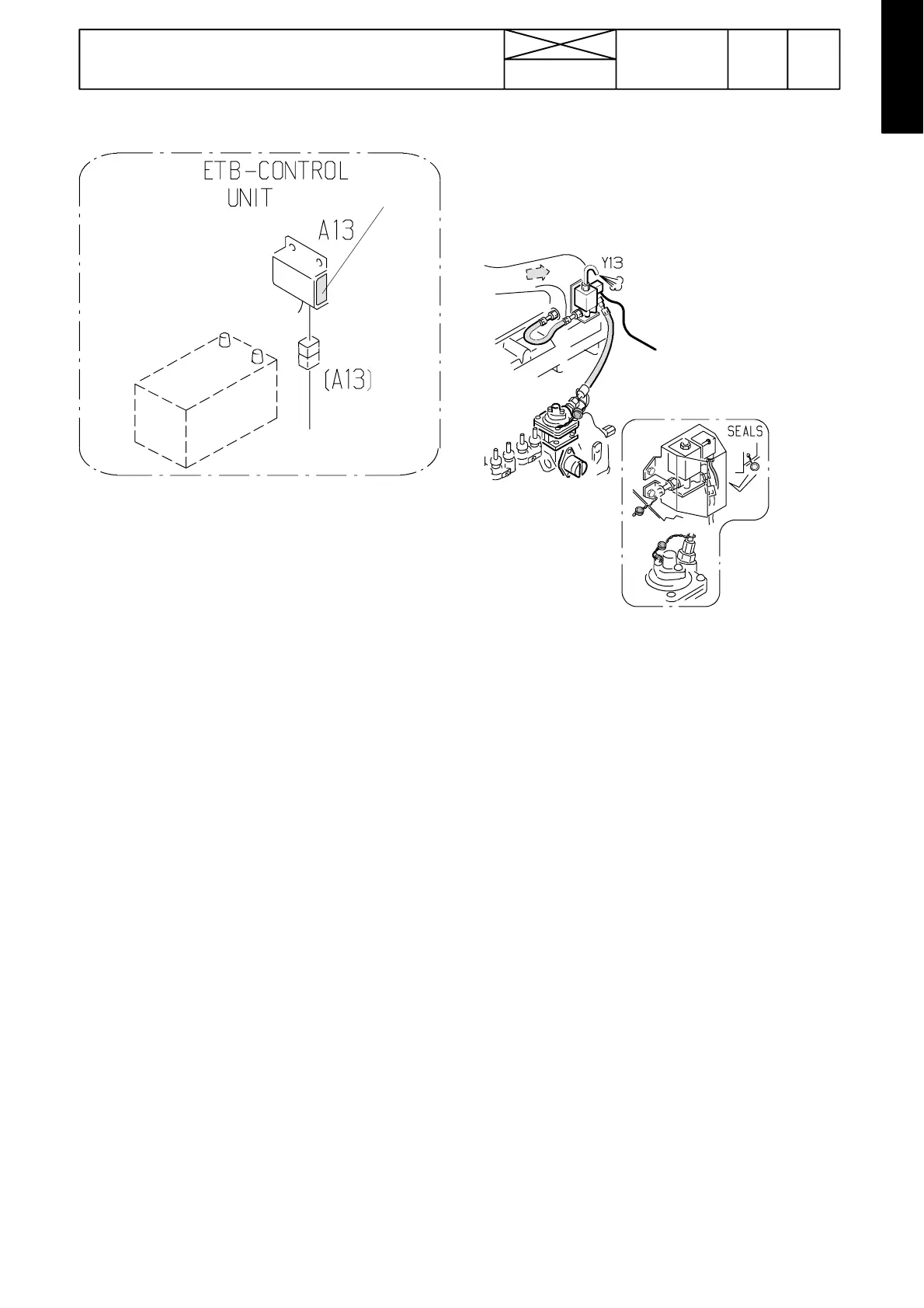

C. Solenoid valve Y13 and boost control

When voltage of 12 V is fed to the solenoid valve pins, the

valve should become magnetic and ”click” must be heard

from the valve. Always when the ETB light illuminates, the

solenoid is energised (higher output range is on).

Seals:

To prevent overriding of the solenoid valve or supply direct

to the solenoid pins, lead seals have been made on the

solenoid valve and on the boost control pipe, see picture

above.

If the solenoid valve has to be changed during the warranty

period, the sealing must be done anew. If the control unit

has to be changed, the solenoid valve seal must also be

broken. If a tractor fails due to the overriding of the control

unit, the warranty does not compensate the costs.

Note! The function of the boost control has been described

on page 223/9, which deals with 6800 tractor, but the func-

tion is the same as on 8750 and 8950 tractors, when the

solenoid valve is energised (open).

The ETB ---light indicates, if the solenoid valve is not func-

tioning, ETB---light then flashes in time 2sec*) on and 0,5

sec off. This flashing indicates that the solenoid valve con-

trol is not on due to e.g. a short circuit or there is no load in

the solenoid output pins, e.g. solenoid wire broken.

*) 1 sec. in versions 2.0 and 3.0.

Loading...

Loading...