345

Model Code Page

33. FieldMaster

1. 8. 2000

332 76200--8950

1. 8. 1998

4. Baler

TEST INPUT

RADAR

0HI

PTO

0HI

WHEEL

TRACTOR

0HI

DIESEL

0HI

IMPLEM.

0HI

TRAIL. 1

0HI

TRAIL. 2

0HI

TRAIL. 4

LO

TRAIL. 7

0LO

TRAIL. 8

0LO

BOMTEST

OK

TRAIL 1: Signal from a piece counter, when the sensor is

activated.

TRAIL 2: Signal from the rpm sensor (RPM 3), when the

shaft equipped with magnets is rotating or signal from the

weight cell. A light load gives little and heavy load many

impulses per second.

TRAIL 4: Signal from the rpm sensor (RPM 2), when the

shaft equipped with magnets is rotating.

TRAIL 7: Signal from the rpm sensor (RPM 1), when the

shaft equipped with magnets is rotating.

TRAIL 8: Not in use

BOOM TEST: Not in use.

5. Slurry spreader

TEST INPUT

RADAR

0HI

PTO

0HI

WHEEL

TRACTOR

0HI

DIESEL

0HI

IMPLEM.

0HI

TRAIL. 1

0HI

TRAIL. 2

0HI

TRAIL. 4

LO

TRAIL. 7

0LO

TRAIL. 8

0LO

BOMTEST

OK

TRAIL 1: Signal from the

weight measuring cell, when

activated.

TRAIL 2: Signal from the rpm

sensor (RPM 3), when the shaft

equipped with magnets is rota-

ting, or from weight cells: A

light load gives little and heavy

load many impulses per

second.

TRAIL 4: Signal from the rpm

sensor (RPM 2), when the shaft

withmagnetsisrotating.

TRAIL 7: Signal from the rpm

sensor (RPM 1), when the shaft

withmagnetsisrotating.

TRAIL 8: Not in use.

BOOM TEST: Not in use.

D. Checking wire connections between

rear socket and display unit

TESTING INPUTS:

1. Switch off current with the ignition switch.

2. Connect a test lamp to poles 5 (---) and 6 (+, battery

voltage) of the rear socket. The lamp is glowing, if the sup-

ply circuit is OK. This can also be made by means of a vol-

tage meter.

3. Switch on current to the tractor. Return in the FieldMaster

menu to the beginning, where are the implement selections

by pressing the yellow arrow button twice to the point SYS-

TEM(canbefoundinthesecondpage).

4. Select TEST INPUT function (use next page---button on-

ce) and make sure that all rear socket information in points

TRAIL 1...TRAIL 7 shows HI mode (TRAIL. 8 is not in use).

5. By means of an auxiliary wire (or by test lamp) connect

by turns with an auxiliary cable the poles given of the soc-

ket and make sure that HI markings (in points

TRAIL.1...TRAIL 7) change to LO:

--- connect poles 1and5 (TRAIL.1)

--- connect poles 2and5 (TRAIL.2)

--- connect poles 4and5 (TRAIL.4)

--- connect poles 7and5 (TRAIL.7)

WARNING! Do not connect poles 6 and 5 (makes short

circuit).

6. If one of the HI markings did not change, check whether

the wires are connected inside the socket. Always when the

poles were connected, the impulse number in the LH side

of the display increased.

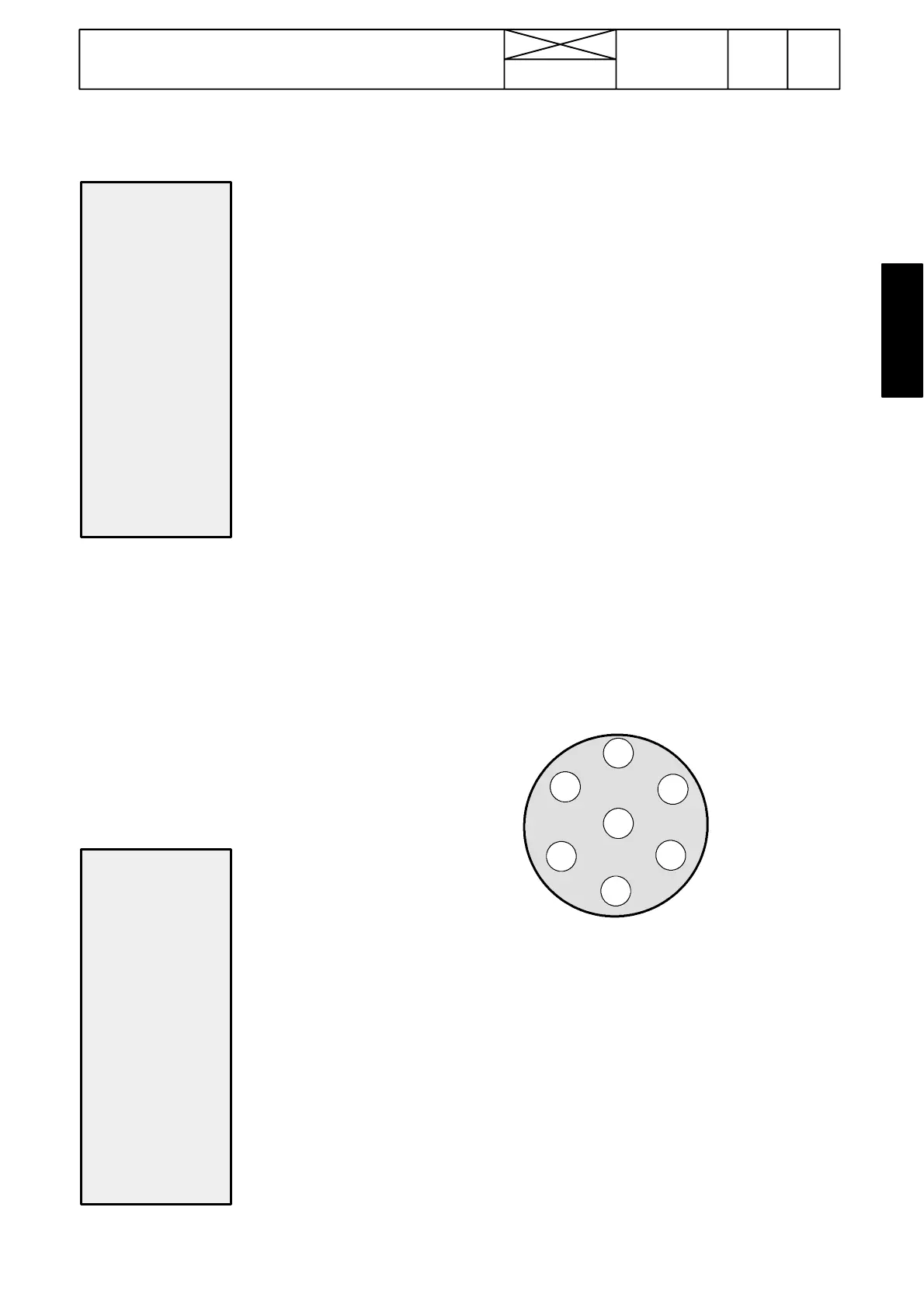

3

4

5

6

1

2

Order of socket poles seen from the rear.

7

Function of pole : Wire colors:

1=RPM sensor, pressure sensor etc. 1=brown no 384

2=Flow meter 2=green no 385

3=Actuator 1, switch (OUTPUT) 3=yellow no 380

4=Wheel sensor, implement sensor 4=red no 388

5=Earthing 5=white GR

6=Supply (battery voltage) 6=black no 17

7=Implement sensor 7=lilac no 383

TESTING OUTPUT:

7. Select test output function (next after test input). Connect

a voltage meter or a test lamp between poles 3 and 6.

Whenyoupressbutton“OUT1”thevoltagemustbeupas

long as you press the button.

Loading...

Loading...