63

Model Code Page

21. Engine

1. 9. 1992

6000--8750

213 7

3. Balancer unit, 420---engines

A. Removing and dismantling balancer

unit

1.Removetheengine(Note! The balancer unit can also be

detached when the engine is attached to the tractor. In this

case,removethefrontaxleandtheoilsump,seealsopage

219/1).

2. Disconnect t he lubricating oil pipe of the balanc er unit.

3. Remove the balancer unit. Take care of any shims.

4. Loosen the locking screws and press out the shafts in the

direction of the locking screws. Remove the counterweights

and thrust washers.

5. Clean all parts.

B. Reconditioning balancer unit

Check the shafts, gear wheels and bushings for wear and

damage.

1. If one of the gear wheels is damaged, change both counter

weights as a complete unit. The gear wheels are not available

separately as a spare part.

2. Remove, if necessary, the old bearing bushings with a suit-

able drift. Before removing them, mark the position of the

bushing oil groove on the counter weigh. Press in new bush-

ings in the correct position. After fitting the bushings should

be reamed to a correct dimension, see Specifications.

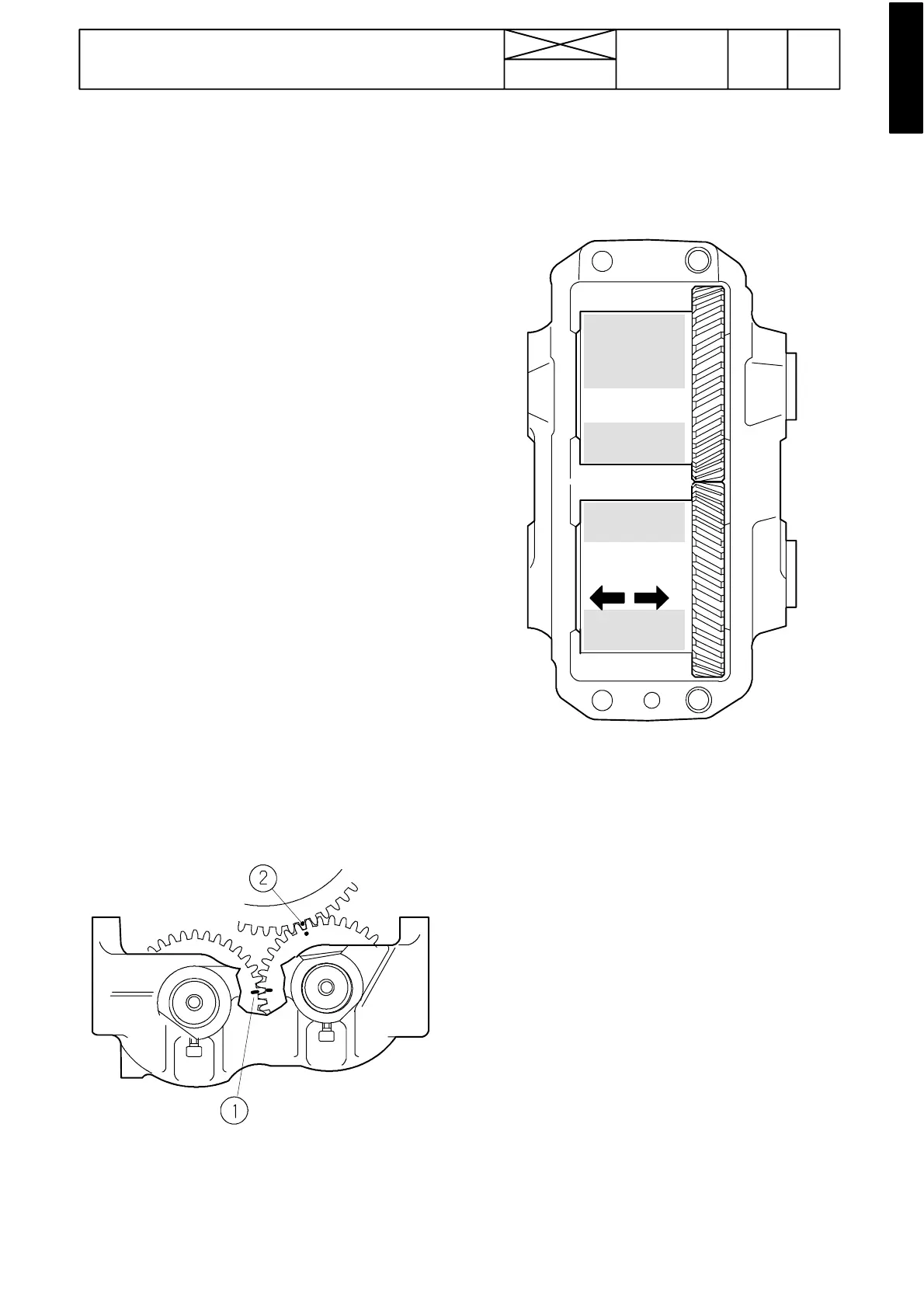

1. Synchronization marking (notch)

2. Marking against crankshaft (punch mark)

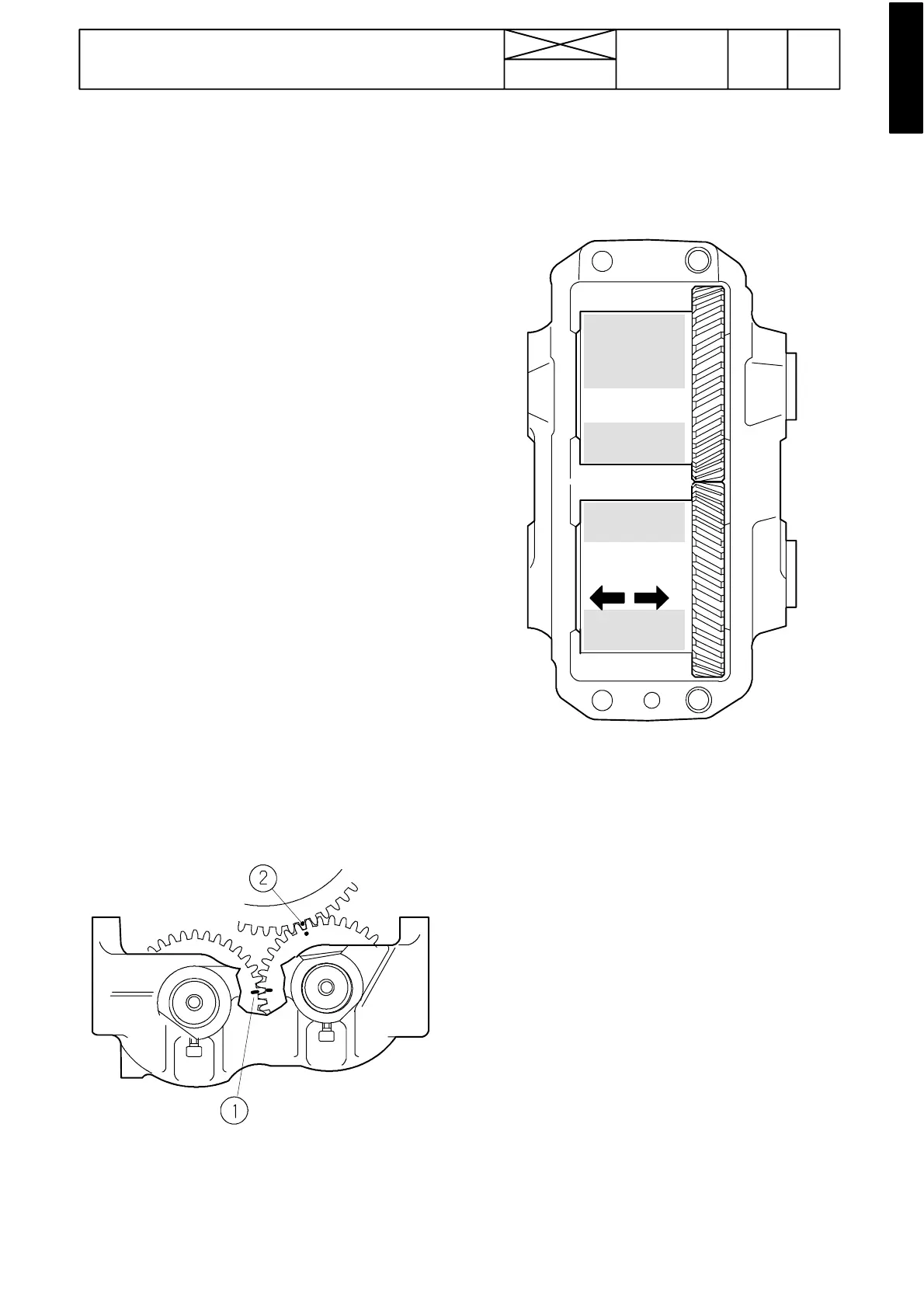

4. Place the weights in the body, observing the no tch mark-

ings. The gear wheel with the punch mark runs against the

crankshaft and should therefore be placed highest. Insert the

shafts, remembering the thrust bearings. Apply thread lock

fluid Loctite 270 to the locking screws, and lock the shafts.

0, 1 --- 0, 5 mm

4. Check that the tooth backlash is 0,05---0, 25 mm and that

the end float is 0,1 ---0,5 mm

Loading...

Loading...