142

Model Code Page

37. Autocontrol 5 / 5.2

1. 8. 2000

370 24

6250--8950

1. 9. 2002

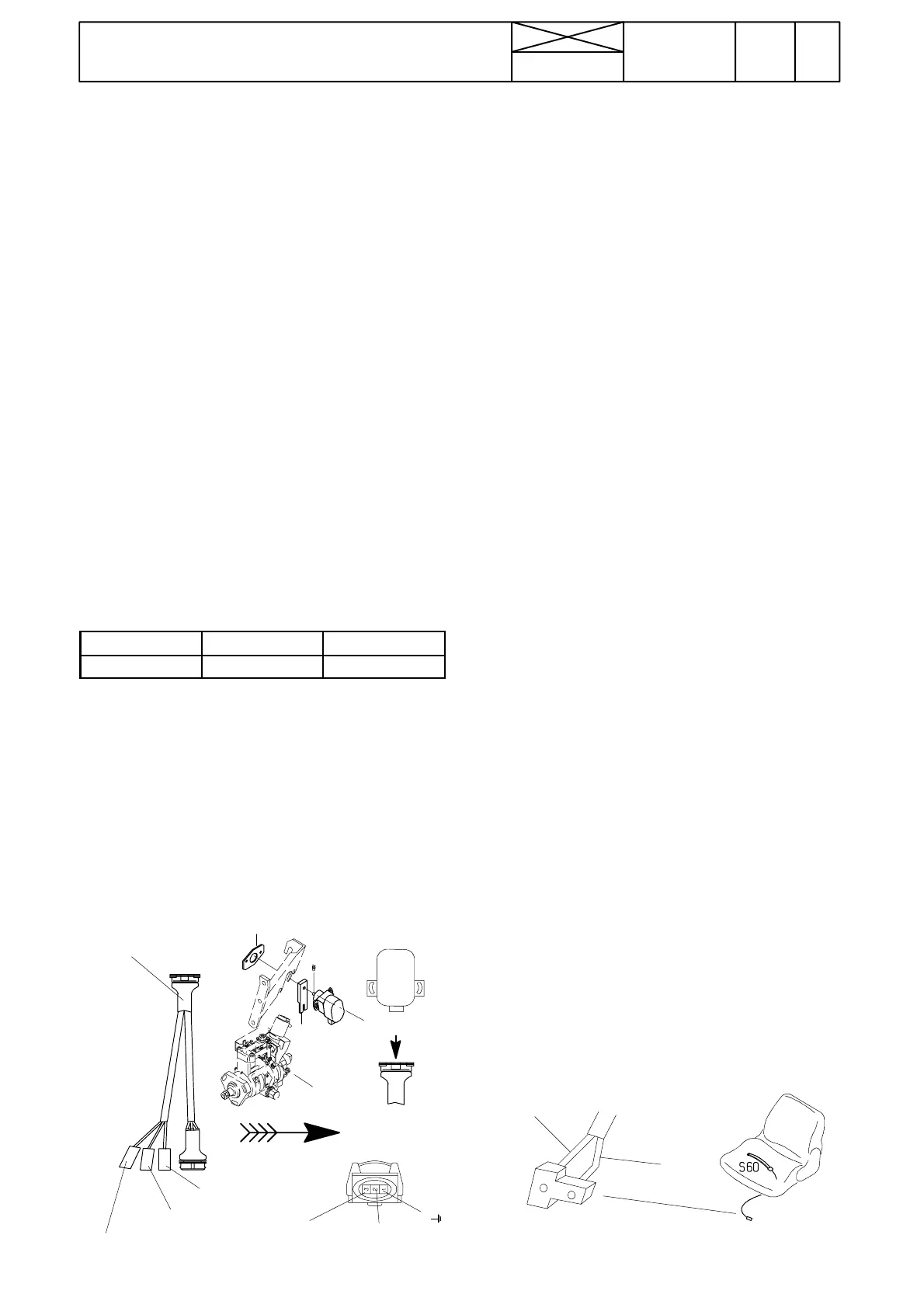

G. Gas pedal (fuel injection pump) posi-

tion sensor B15 in AC 5 (AC 5.2, see page

371/14).

Note! If this s ensor is faulty, there occur malfunctions in the

DPS auto matic speed change (auto1, aut o2). Also a faulty

engine speed sensor can cause this kind of malfunctions.

If the position sensor has malfunctions, the self--- diagnosis

shows the fault code A313.

1. Check in the test mode FII (table b on page 370/11),

whether t he pedal values are between the given limits. If the

function is incorrect, check the position sensor bearings (no

clearance) fitting and wires and wear of the pump pin. Also

check the sensor. Also check the connector X1A (in engine

compartment).

2. Measure, if needed, the position sensor voltages. Check

the voltages always before calibrating the pedal. Connect

ETV 894 100 between the sensor and its connector (see

picture below). If ETV is not available, measure the supply

voltage in the wire loom connector (see pictur e on the next

page). Signal voltage can be measured from control unit A1

connector A1A3/4---A1A3/5 (see page 370/25). The volt-

ages can also be measured in connector X1A.

--- measure the supply voltage (7,7...8,3 V) between pins 1

and 3.

--- measure signal voltage between pins 1 (ground) and 2

(signal). Ensure that the vol tage value changes evenly

when moving the position senso r lever. Adjust the sensor

position if necessary. If the position sensor is faulty, fit a

new one in the correct way (punch mark on shaft towards

lever) and perform the calibration of the pedal. Adjust the

position of the sensor. Fasten the sensor in point, in which

thesensorshaftisinthesamelinewiththepumplever

shaft (see point A in picture below).

Gas pedal

Pedal up Pedal in bottom

Signal voltage 5,7 ---5,8 V 1,5---4,0 V

Adjust the pedal “upper” value and check then that the

pedal “bottom” position value is within the given limits. Se-

cure the screw, which fasten the arm to the sensor spindle

with Loctite 222.

3. P erform the pedal calibration according to instr. B on

page 370/15. If the calibration failed, turn the sensor into a

little different position and try again the calibration. When

needed, try the test with a new senso r.

Only on model 8950 can the sensor be fitted in different

way with fitning set no. 345 60 300 (see fitting instruction

39.25)

Note! Thecalibrationofthegaspedalmustbedoneac-

cording to the periodical maintenance program.

3 Red, +7,7...+8,3 V

2Blue,signal

1Black,earth

ETV 894 100

B15, B16

A

A

1

2

(signal)

3 (+7,7...8,3 V)

A

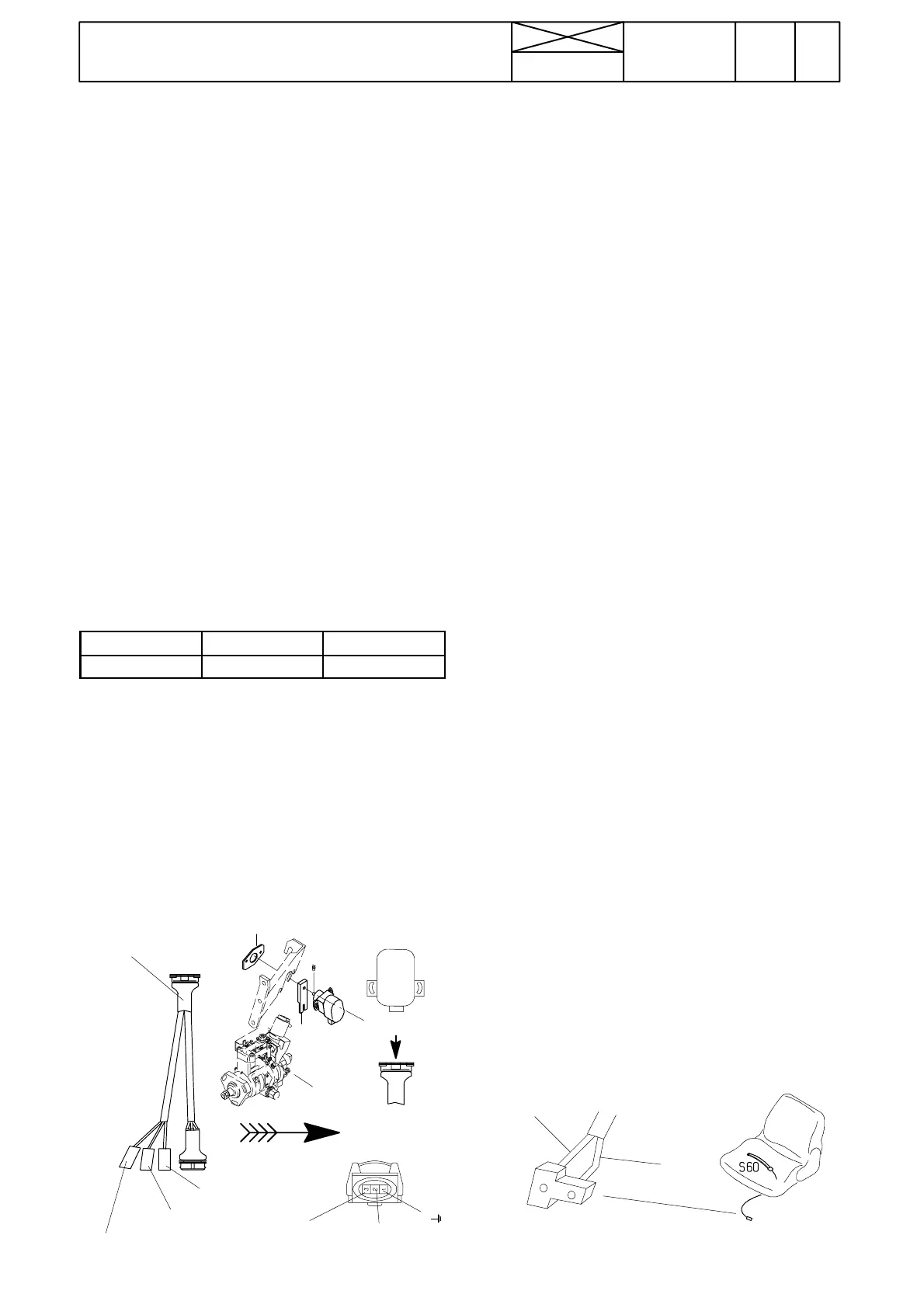

H. Detection of driver in AC 5 and 5.2

Purpose of the switch S60

InAC5/5.2isusedforsafetyreasonssocalleddriver

detection system. The detection switch prevents uninten-

tional engagement of the PowerShuttle in the situations, in

which the driver does not sit on the seat.

Function

TheswitchinquestionhasbeenconnectedtoAC5/5.2

contr ol unit pin d05. When the driver is sitting on the seat

(weight must be over 30 kg), the switch contacts are

closed and d05 is activated (GND control). The function of

the switch can be seen in table a on page 370/10 (AC 5) or

on page 371/8 (AC 5.2). When the driver leaves the seat,

the switch contacts open (delay 6 seconds. 4 sec. in pro-

gram versions 38, 40, 41 and in AC 5.2 30 sec. if the clutch

pedal is depressed).

Function in different situations

When the driver engages the PowerShuttle direction, the

AC 5 control unit checks the signal from the seat. If there is

not a signal (driver does not sit on the seat) , the direction

arrow in the AC 5 display starts to blink and the direction is

not engaged. After this the direction can be engaged just

when the shuttle lever is moved to the parking brake posi-

tion, the seat signal is activated (driver sits on the seat) and

the direction is re---engaged.

If the direction has been engaged (or is being engaged)

and the seat signal disapperas (e.g. driver stands up from

the seat), a counter is started. The counter damps possible

disturbing information, which can appear e.g. when driving

on an uneven ground. If the seat signal remains floating

(driver does not sit on the seat) over 6 seconds (4 sec. in

program versions 38, 40, 41 and in AC 5.2 30 sec. if the

clutch pedal is depressed), the Shuttle is disengaged and

the direction arrow starts to blink. After this the direction can

be engaged just when the shuttle lever is moved int o the

parking brake position, the seat signal is activated and the

Shuttle direction is engaged again.

Checking function of the sensor

--- in the test mode FII (digital input d05)

--- with ohmmeter in the wire loom connector ( beside the

seat base). The switch is normally open, but closes, when

driver sits on the seat

Changing the sensor

--- remove t he seat upholstery

--- detach the sensor from its holder by pulling it

--- remove the sensor together with wire

--- pass a new sensor wire and press the sensor into its

holder.

--- refit the upholstery. Connect the connector. Check the

function.

Brown

wire

Blue

wire

Loading...

Loading...