A

B

B

A

D

A

C

D

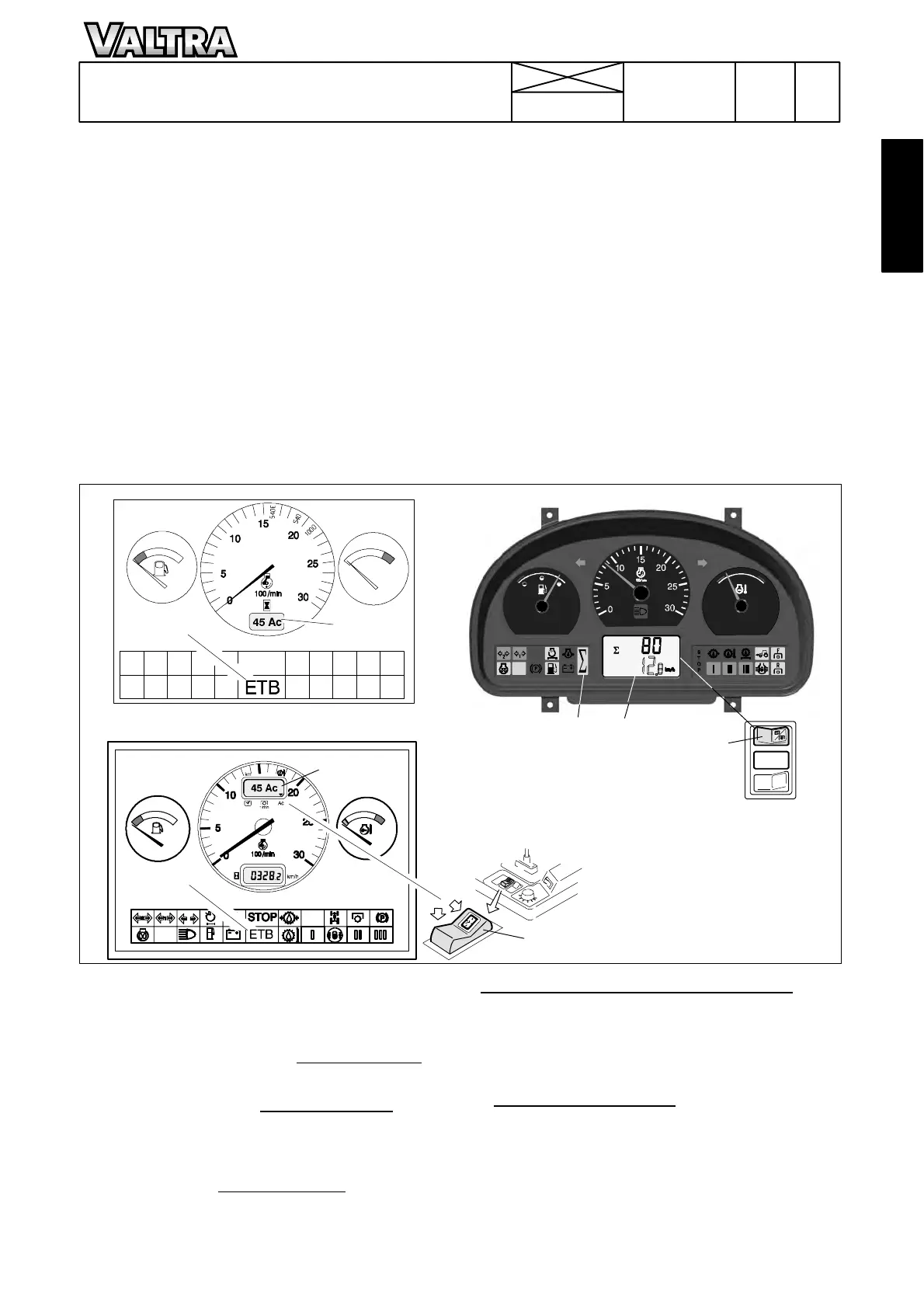

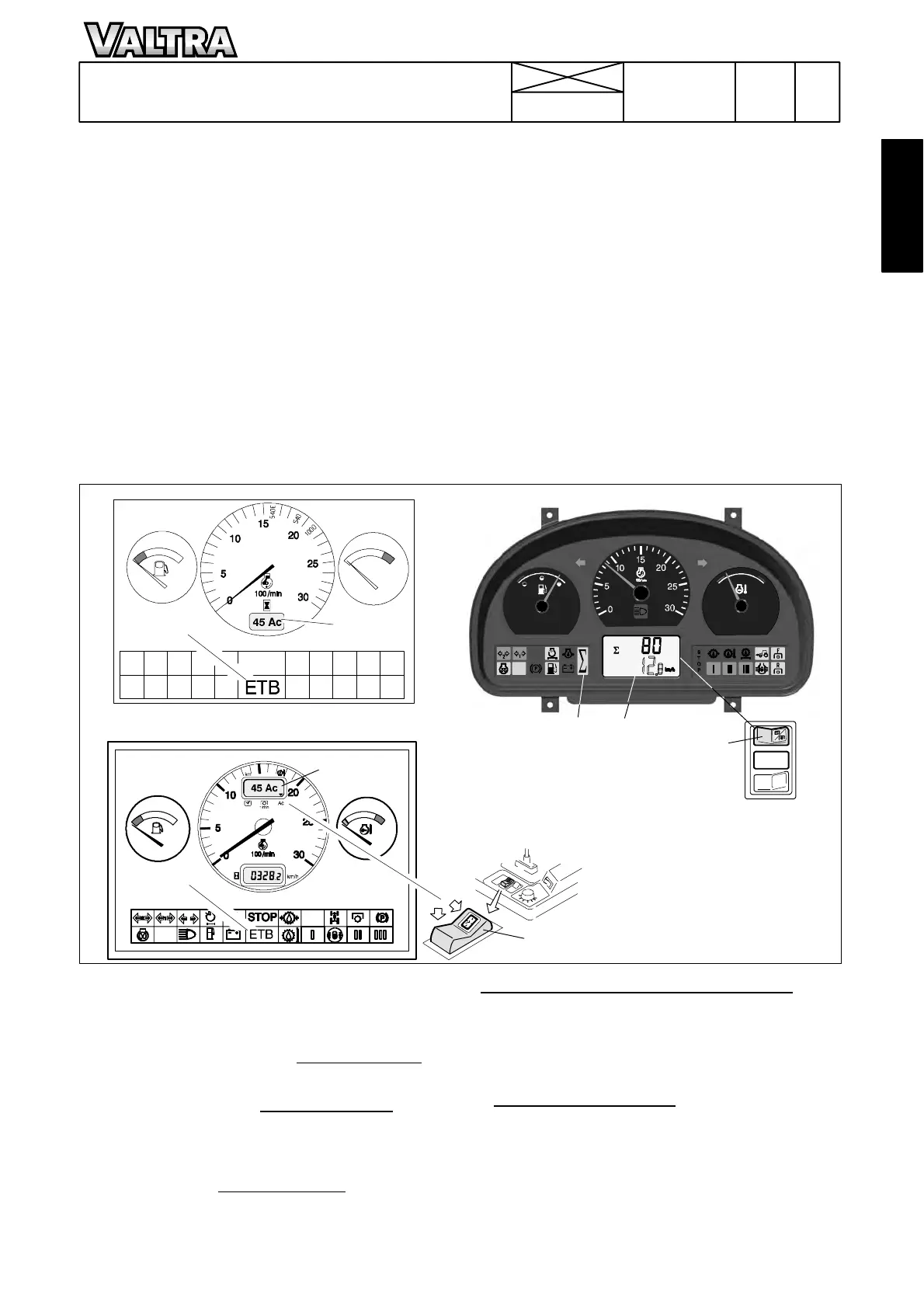

Standard instrument

Agrodata--- instrument

Agroline ---instrument

85

Model Code Page

8750, 8950

313 1

1. 10. 1999

31. Σ --- p o w e r s y s t e m

1. 9. 2002

1. Descrip tion

A. General

Engine (634 DS/634DSBIE) on Valtra 8750 and 8950 trac-

torshasasastandardequipmentΣ ---power system

(double output system). Tractor transmission max. output is

160 hp, but max. PTO output is 190 hp (8750) / 200 hp

(8950).

The automatics οftheΣ---power system have been

designed so that the engine output for the tractor trans-

mission never is larger t han 160 hp. The injection pump has

a boost control. Pressure loading from the intake manifold

can be cut with the aid of a solenoid valve. When the PTO

loading is high, the intake manifold pressure affects the

membrane of the boost control unit (solenoid valve ener-

gised), which facilitates movement of the fuel injection

pump control rod to the high output range.

When the PTO loading decreases, the solenoid valve is

Differences in the dashboard:

On 8750 and 8950 tractors there is a digital instrument (A)

which shows as a percentage, ho w large a part of the trac-

tor total output is transmitted via the PTO unit, when the

PTO is engaged. At other times the Standard instrument

shows tractor running hours.

If tractor is equipped with the Agrodata ---instrument

(see

code 331 page 1),theAc---display mustbeselected in

the upper digital display by using switch (D) (see black

arrow) before the PTO %---display can be seen.

I n L C D --- d i s p l a y o f t h e A g r o l i n e --- i n s t r u m e n t

the upper row

canbechangedbypressingtheRHsideedgeofthe

switch (D), before t he PTO % ---display can be seen. (see

code 333 page 3)

closed (which is controlled fully automatically by the control

unit of the system) and the fuel pump co ntrol rod can move

to the low output range.

The torque of the PTO unit is measured by two sensors.

One sensor is placed at the flywheel under the starter motor

(earlier at the engine front end. On 8950 Hi in front of the

DPS) and another in the PTO unit. These sensors indicate a

twist of the long PTO shaft as a phase shift, which in turn

indicates the torque transmitted by the PTO unit. Always

when the PTO is disengaged, the sensor phase shift is

zeroed automatically to avoid inaccuracies caused by per-

manent deformation of the shaft or phase shift changes

caused by repair works.

The Σ---power system is controlled automatically by the

control unit.

ETB light

(B) Standard and Agrodata ---instruments.

When the higher output range of the engine is engaged,

there is a light ETB in the warning light panel (ETB=Extra

Turbo Booster). The ETB --- light has also a fault diagnostic

function. It indicates by flashing, if the system has malfunc-

tions.

Σ light

(C) Agroline---instrument.

When the higher output range of the engine is engaged,

there is a light Σ in the warning light panel. The Σ --- l i g h t h a s

also a fault diagnostic functio n. It indicates by flashing, if

the system has malfunctions.

Note! If an electric welding is done on the tractor or on the

trailer or implement, which are attached to the tractor, both

battery cables must be disconnected. Otherwise the

Σ---Power system may be damaged.

Loading...

Loading...