65

Model Code Page

21. Engine

1. 8. 2000

6000--8950 214 1

1. 1. 1994

Timing gears (Op no 214)

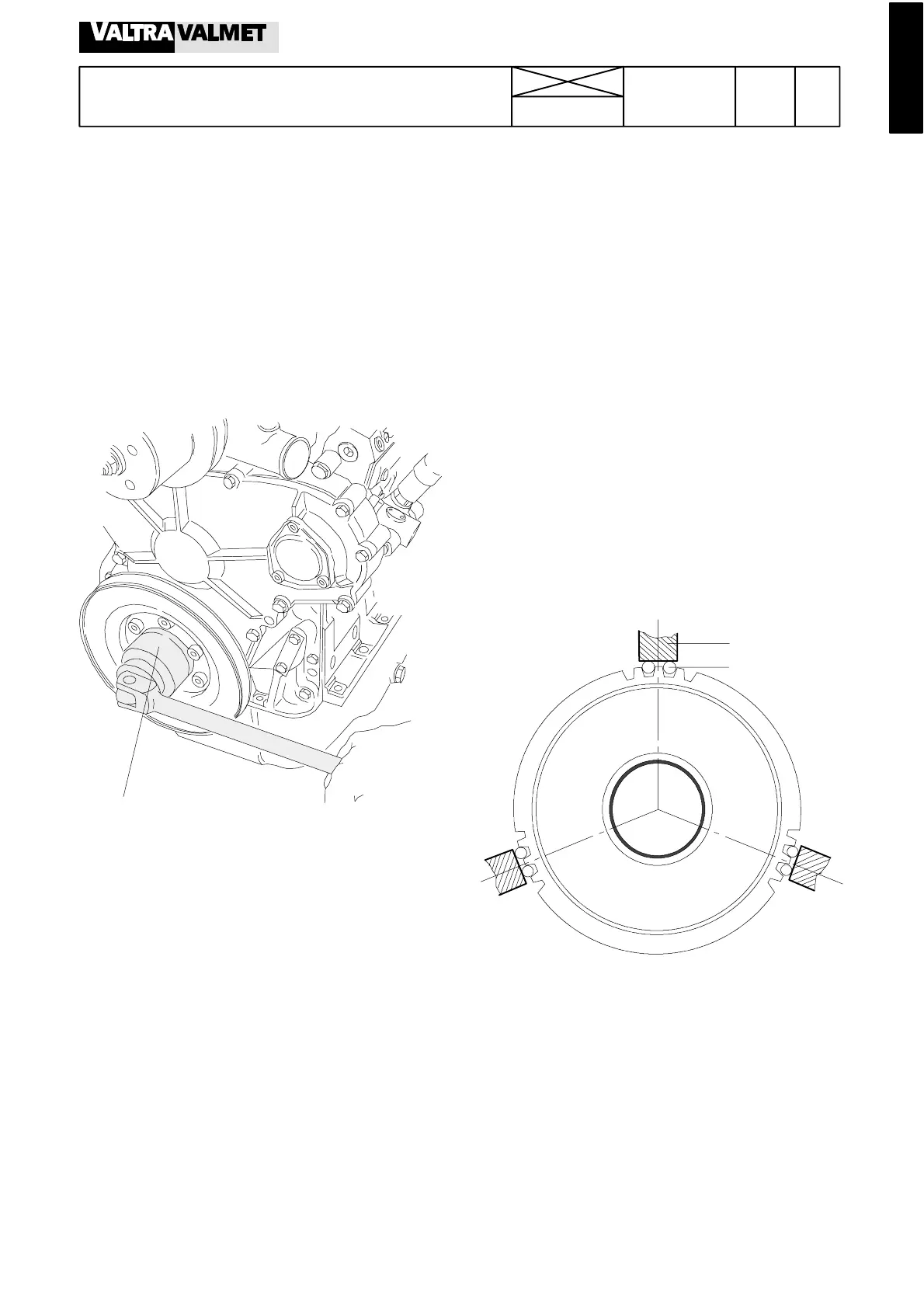

A. Removing timing gear casing

As the timing gear casing forms a seal against the oil sump,

the casing cannot be removed without first removing the

frontaxleandtheoilsump(seepage219/1 for working

order).

1. Detach the engine (or the oil sump).

2. Remove the cooling radiator, alternator and the fan belt

(if not removed earlier).

9101 65700

3. Loosen the crankshaft nut (special tool 9101 65700 for

320, 420, 620 engines and tool 9024 55800 for 634

engines) and remove the bel t pulley/hub.

Note! Warm the nut with a hot---air blower before unscrew-

ing (locking fluid. Do not damage the seal). The thread is

normal RH thread. Support the key so that it cannot slip

(600 Nm/1000 Nm). Rotation of the crank shaft can be pre-

vented by fastening a support on the hub (remove the belt

pulley and fasten the support to the hub) or you can use

an air po wered nut opener, and the crankshaft does no t

rotate . When needed, the hub is removed with an extract or.

Note! On 620---engines the belt pulley must be removed

before unscrewing the nut.

4. Remove the timing gear casing cover and the oil deflec-

tor ring at the front end of the crankshaft.

5. Remove the injection pump.

Note! If the timing gear casing is not to be changed, the

injection pump can remain in place. In which case disco n-

nect all leads and pipes from the pump.

6. Unscrew the idler gear bol ts (17 and 22 mm). Remove the

flange, gear wheel and bearing journal.

7. Extract the camshaft.

Note! If the cylinder head and valve mechanism have not

been removed, the tappets must be prevented from falling

down, see Op. 212 2B.

8. Remove the timing gear casing (13 mm). Ensure that all

sealing surfaces are not damaged.

9. Remove the crankshaft front sealing ring from the front cas-

ing and clean all the parts that have been removed.

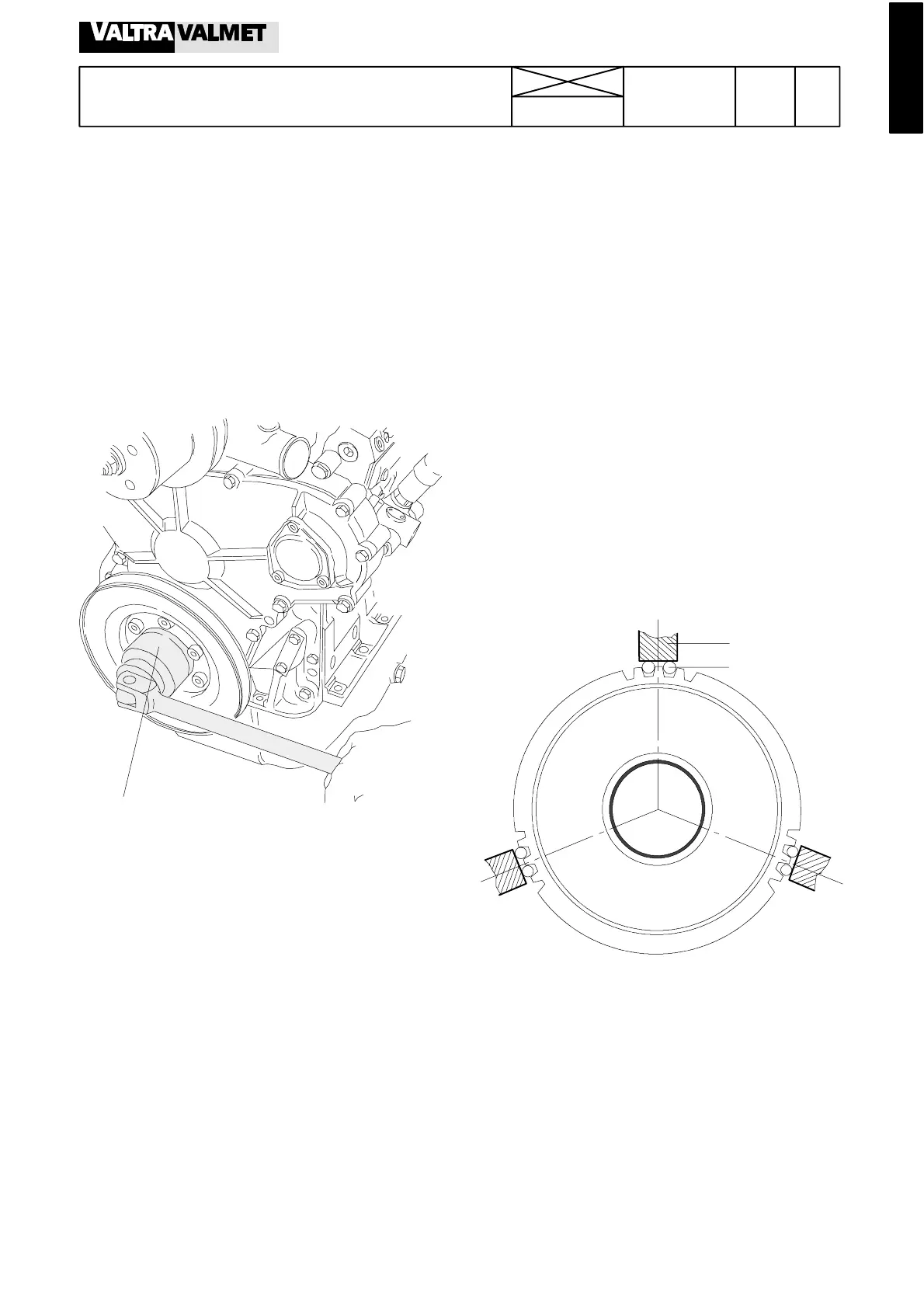

B. Reconditioning i dle r gear

If the idler gear bushing is changed, press in a new bushing

so that its rear edge is 0,1 ---0,25 mm inside the gear wheel

rear edge (see picture on next page).

1

2

1. Chuck of lathe

2. Roller ø=5 mm

Machine the idler gear bushing inner diameter to a correct

dimension after fitting. Centre the idler gear according t o fig-

ure above so t hat tooth backlash is kept the same.

Loading...

Loading...