75

Model Code Page

21. Engine

1. 9. 1992

6000--8750 216 1

Inlet and exhaust system,

turbocharger (Op no 216)

An engine that is equipped with a turbocharger is a great deal

more sensitive to disturbances and impurities in the inlet and

exhaust systems than a conventionally aspirated engine.

Therefore special attention should be given to the whol e inlet

and exhaust system.

A. Checking air cleaner

The engine performance and length of service life depend to

a great extent on the state of the air cleaner. A defective air

cleaner allows impurities to pass through, which in time dam-

age the turbocharger and the engine. A blocked air cleaner

lowers the engine output and also causes oil leakage through

the sealing ring on the turbocharger shaft.

Note! The safety filter inside the main filter should not be re-

moved unnecessarily, for checking or cleaning. The safety

filter must not be cleaned, but should be changed once a year

or when necessary (see Operator’s Manual)

B. Checking inlet and exhaust system

Important! Leaks in the inlet or exhaust system markedly

lower the effect of the turbocharger. Because of the pressure,

even small leaks in the manifold or in the turbine inlet contact

flange quickly increase in size. For t his reason all l e aks must

be dealt with immediately.

1. Inspect the pipes and sealing surfaces between the air

cleaner and the turbocharger, as well as between the turbo-

charger and the induction manifold. If the inductio n manifold

is dusty on the inside, there is a leak in either the air cleaner

or the induction pipes. Remedy the leak.

2. Clean the induction manifold sealing surface. Check that

the sealing surface is flat using a straight ruler. If the surface

is not flat or it has s cratches, machine or renew the induction

manifold. On 620---engines ensure that the cylinder heads are

parallel.

3. Fita new gasket and fasten theinduction manifold. Tighten

the manifold fixing screws to a torque of 30 Nm. Fasten the air

pipes carefully..

4. Check that the exhaust manifold is air tight. Tighten the

bolts to 50 Nm and inspect for any damage (cracks, deforma-

tion, corro sio n etc.). Check also the connection between the

turboc harger and the exhaust manifold.

5. Remove the manifold if necessary. Clean the sealing sur-

faces and remove any carbon deposits. Check that the seal-

ing surfaces are flat. I f the fastening flanges are twisted or

there are scratches on the sealing surfaces, machine the

flanges or renew the exhaust manifold.

6. Ensure that no loose objects or impurities have entered the

exhaust pipe or the silencer. Any such loose objects or impu-

rities can increase the back pressure for the exhaust gases

from the turbine wheel.

C. Checking turbocharger

If a fault is suspected in the turbocharger it can be l o c ated in

the following way:

1. Visually inspect the turbine and compressor wheels. The

vanes must not show any signs of damage, deformation or

wear caused by foreign objects.

2. Investigate any oil leaks through the sealing rings on the

shaft in the turbine and compressor housing.

N.B! At low idling there is always a certain amount of oil leak-

age on the compressor side. However, this should not cause

too much concern unless the oil consumption is too great.

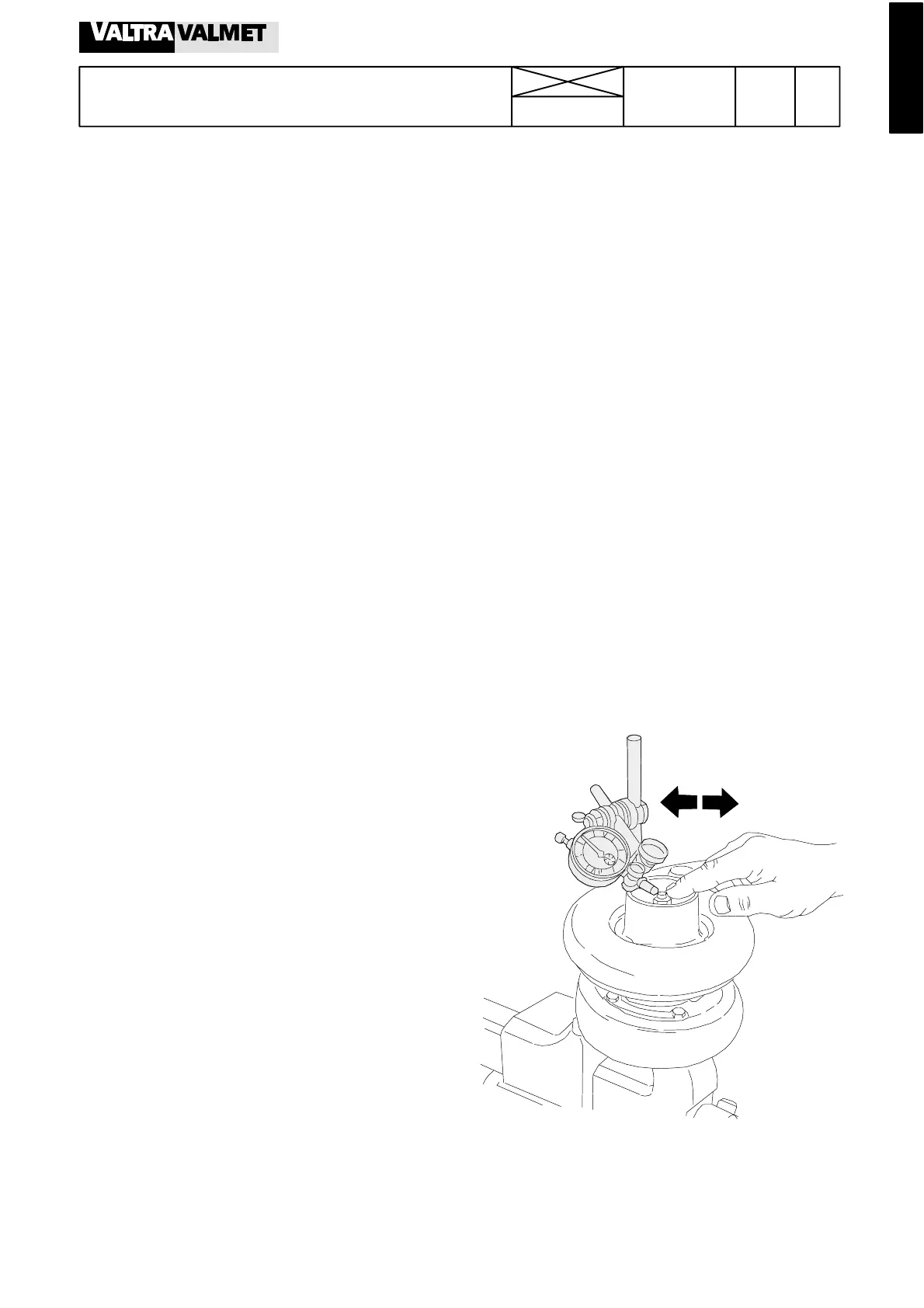

3. Check the turbine shaft running clearance. Place the stylus

of a dial gauge against the shaft and move the shaft sideways.

refer to the clearance given in the specifications on page

210/9.

Loading...

Loading...