168

37. Autocontrol 5.2 (K41107---)

1. 8. 2000

371 11A

6250--8950

1. 9. 2002

Model Code Page

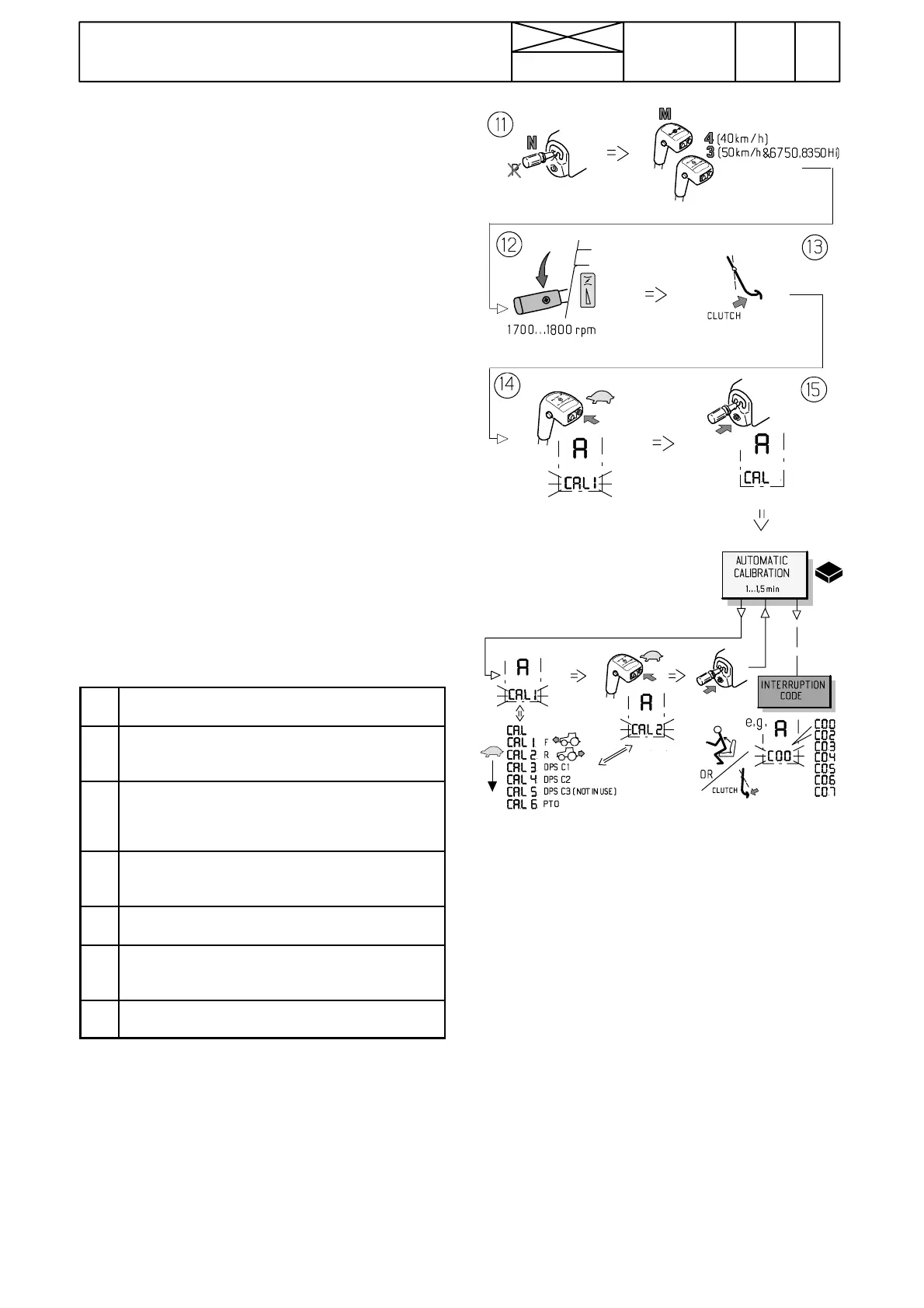

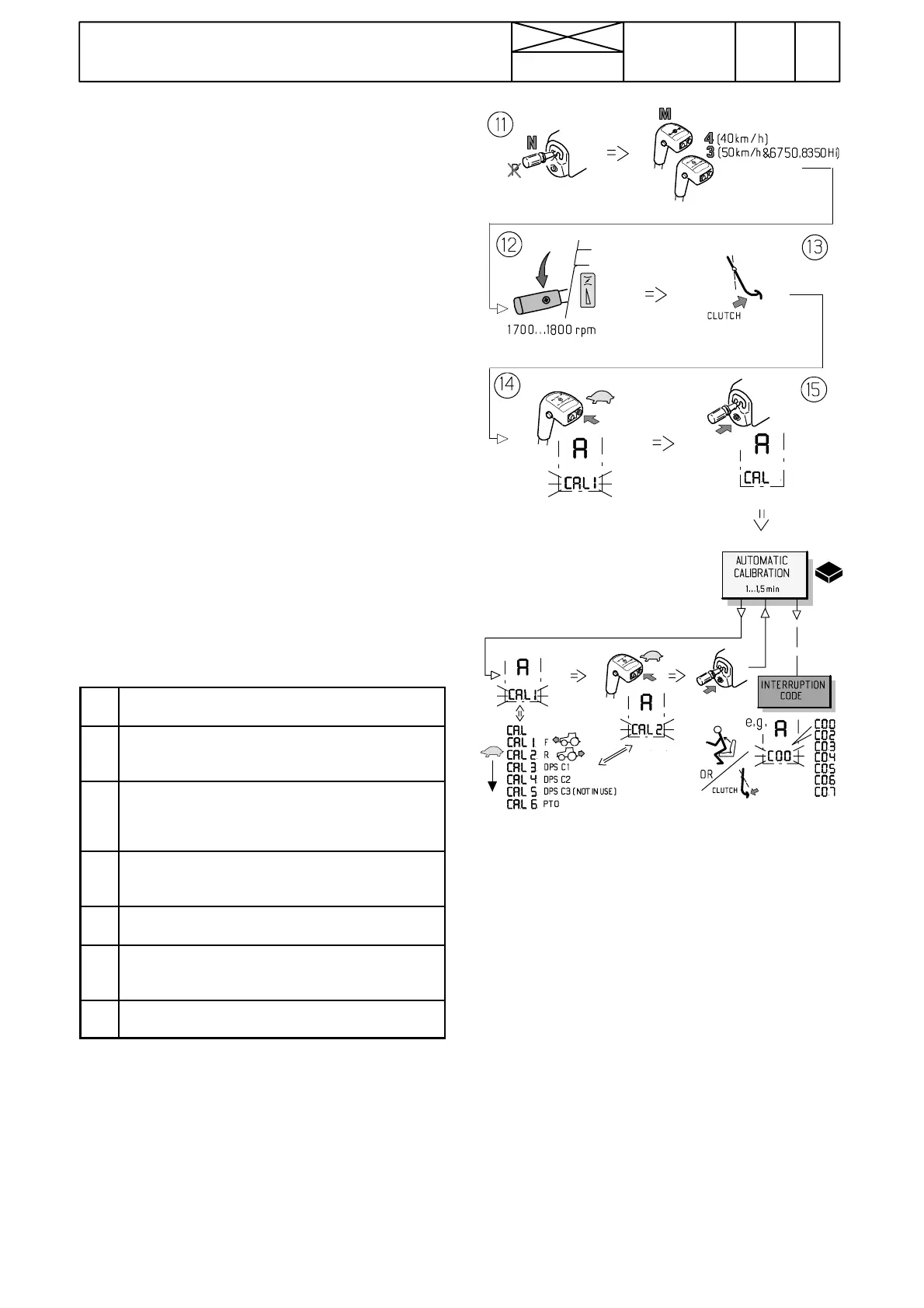

11. Move the shuttle lever to the neutral position N. Engage a

mechanical gear: In 40 km/h models gear M4 a n d i n 5 0 k m / h ---

models (also 6750 and 8350Hi models) gear M3.

12. Adjust the engine revs with the hand throttle to 1700---1800

r/min.

13. If the clutch pedal is depressed, lift it up.

14. Step with the DPS push buttons in the menu from starting

level (CAL, blinking) downwards and selec t desired function:

CAL 1 = Calibration of F--- clutch (Y11).

CAL 2 = Calibration of R--- clutch (Y12)

CAL 3 = Calibration of DPS--- clutch (Y4)

CAL 4 = Calibration of DPS--- clutch C2 (Y6)

CAL 5 = Calibration of DPS--- clutch (Y17), NOT IN USE

CAL 6 = Calibration of PTO cl utch (Y2).

15. Confirm desired blinking calibration point (e.g. CAL 1) with

DPS pre---programming button, after which there is text CAL

without blinking in the display lower row (during the whole ca-

libration). After this the calibration proceeds automatically and

stops either to an interruption code or to a successful calibra-

tion. When the calibration has been successfully completed, e.g.

text CAL1 starts to blink in the display (the calibration symbol of

the clutch, which has been calibrated is blinking). After this can

be stepped to another calibration point etc. A calibration of a

clutc h takes about 1...1,5 minutes.

NOTE!

--- Wait during the whole calibration procedure and do not touch

the controls. During the automatic calibration DPS speed 1 is en-

gaged automatically.

--- The calibration can be interrupted by depressing the clutch

pedal (or by getting up from the seat). The calibrating mode can

be left by switching off the current.

--- With an aid of the interrupt ion code the contro l unit informs that

the calibration has failed and the reason.

Interruption codes:

C00

The seat switch does not recognize a driver or clutch pedal

has been depressed during calibration.

C02 Parking b rake applied, enginerevswrong, gearbox tempe-

ratute wrong, mechanical gear is not eng aged or tractor on

a slanting ground.

C03 Initial pressure calibration does not find a correct value in

spite of many attempts. The tractor starts to move too

sharply. Ensure, that the tractor is on the level ground and

that the correct mechanical gear has been engaged.

C04 Clutch which is calibrated does not transmit enough high

torque. E.g. piston or valve trapped, pressure of low pres-

sure circuit is too low, leaks etc.

C05 Calculated initial pressure index is not within given limits (li-

mits --- 9...+9).

C06 Calculated pre--- filling index is not within given limits (e.g.

clutch piston does not move freely or clutch worn out) (li-

mits --- 9...+9)..

C07 The pre--- filling time calibration does not find a correct va-

lue in spite of many attempts.

Note! If the automatic calibration does not succeed, try to cali-

brate the clutch manually(see page 370/24H). If a very small

or large index must be used (below ---6 or over +6), the fault

can lie in the mechanical parts or in the hydraulics.

The calibration can also fail, if the fault lies in:

--- Control unit

--- W i r i n g l o o m s

--- Battery (voltage too low)

--- Proportional valves

--- Low pressure circuit of hydraulics (18 bar)

--- Mechanical parts (clutch pack etc)

--- Clutch return springs faulty or wrong number of springs.

Loading...

Loading...