654

Model Code Page

41. Clutch

1. 4. 1997

6000--8750 411 6

8. 11. 1990

10 mm

0,01 mm

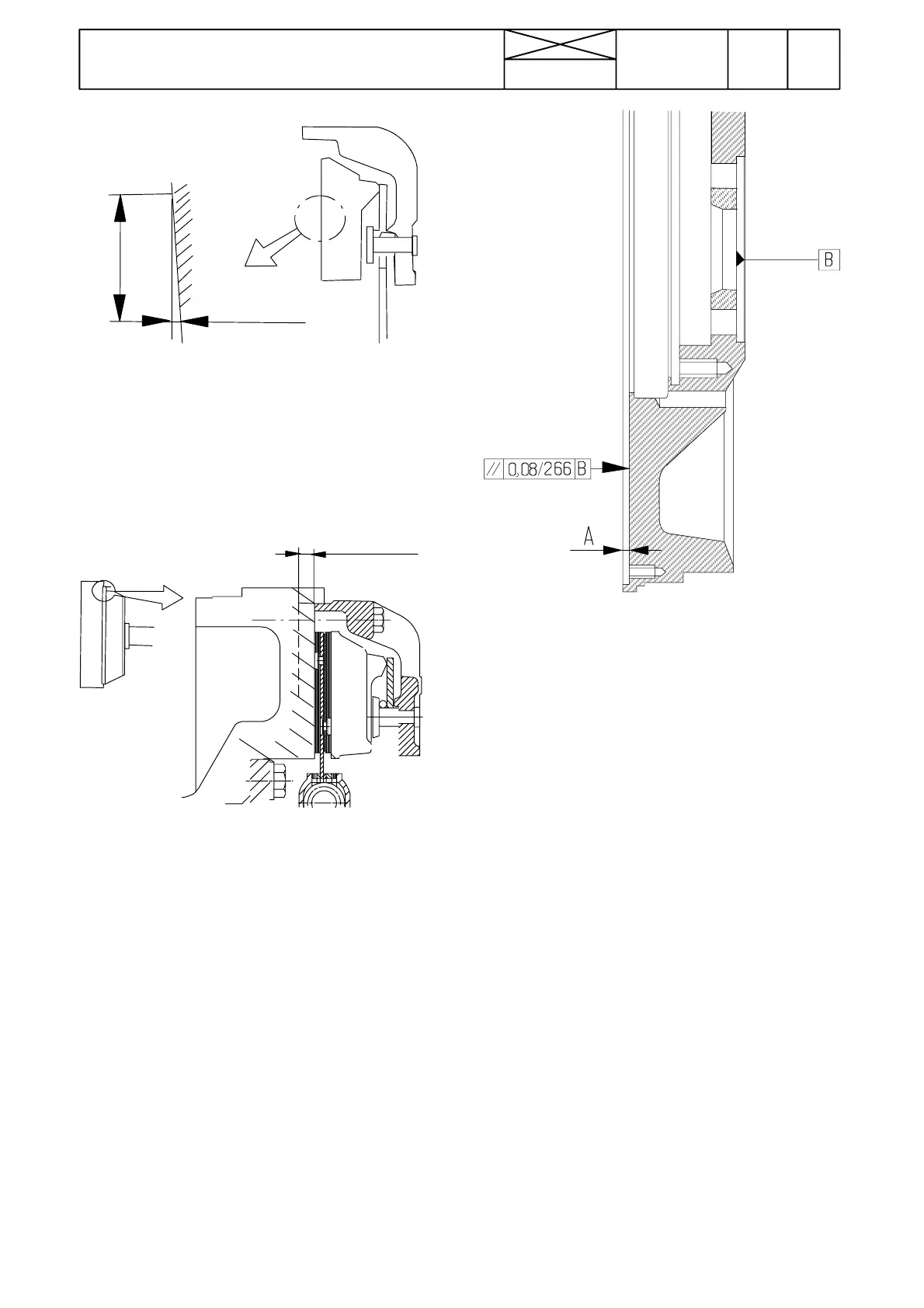

Checking concavity of pressure plate

A new pressure plate is flat to slightly co ncave, max. 0,01/10

mm: convexity, i.e. the reverse state, must not occur. The rea-

son for the concave surface is to allow engagement to start at

the outer edge of the lining where the disc is least sensitive to

slipping. A grooved or otherwise deformed clutch must be

changed.

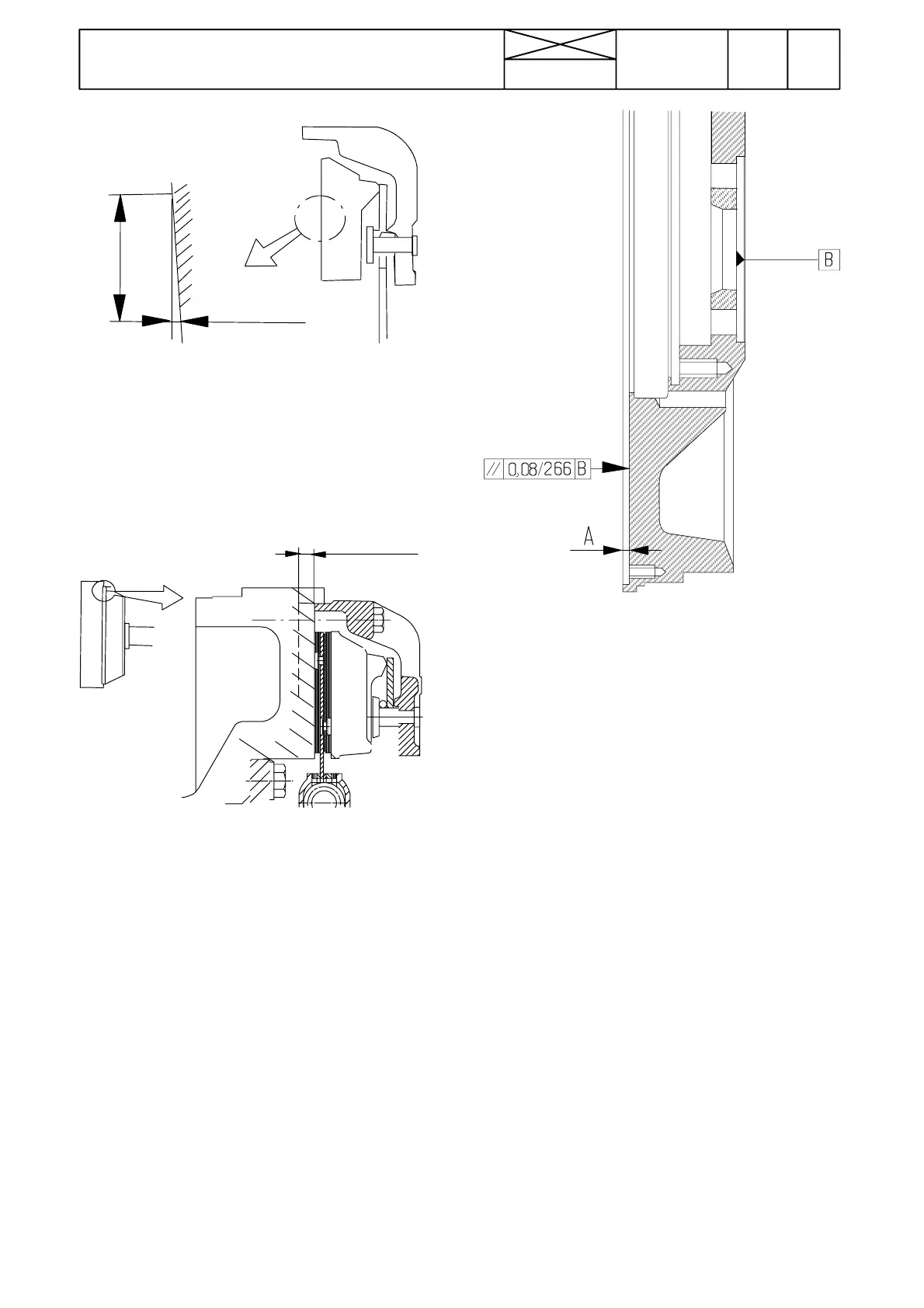

max. 2 mm (4 mm)

Machining flywheel

The flywheel c an be machined 2 mm without any further ac-

tion. For additional machining the holes for the clutch attach-

ing bolts must also be deepened. The maximum machining

of the flywheel is 4 mm.

Important! When machining the flywheel, it is important to

observe that the clutch surface and the flywheel fixing surface

are parallel.

Measurement A on a new flywheel is 6±0,3 mm, and max

allowable value is 10±0,3 mm.

Loading...

Loading...