Chapter 8 Troubleshooting ALPHA V40

Version 18.07.06

105

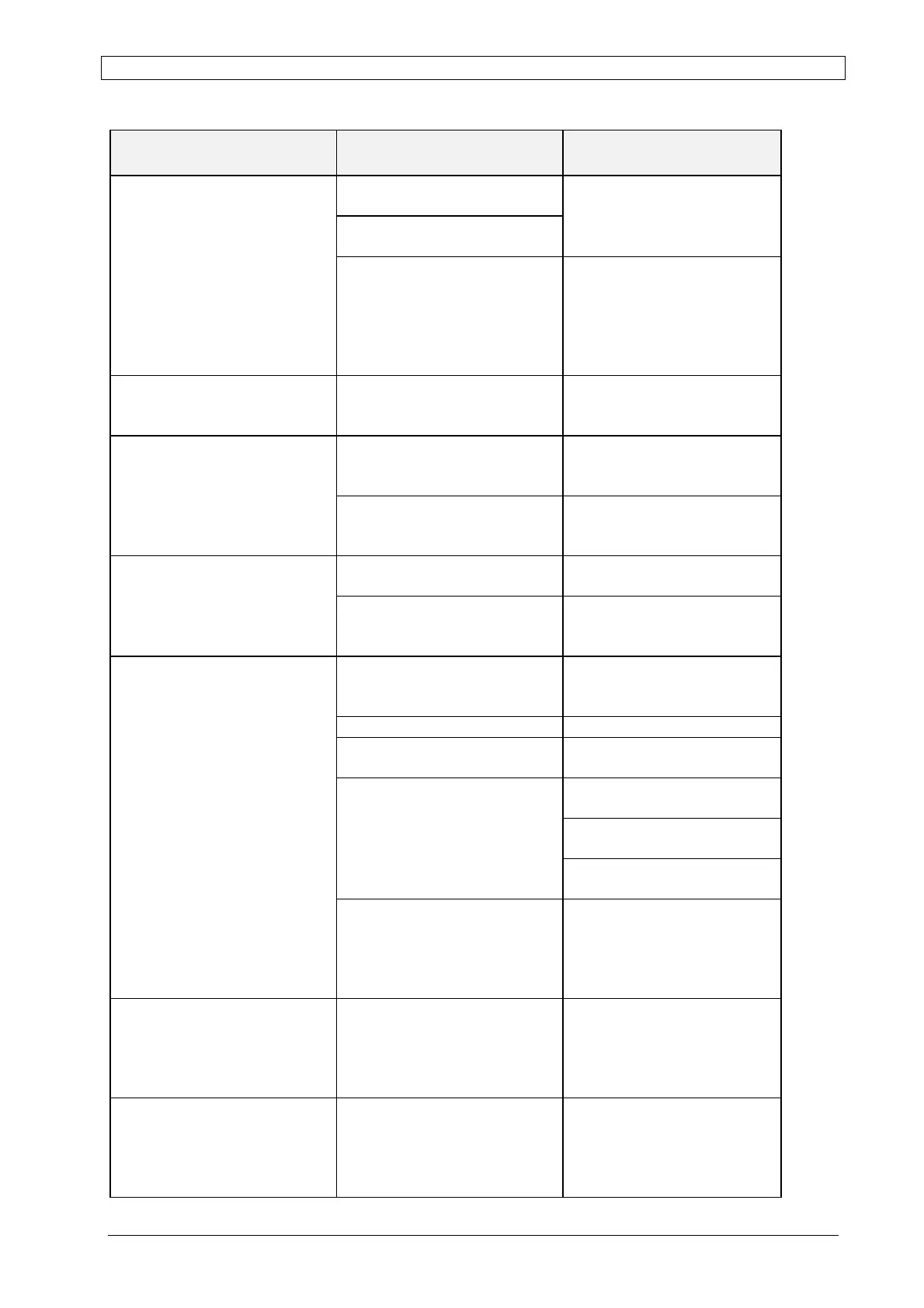

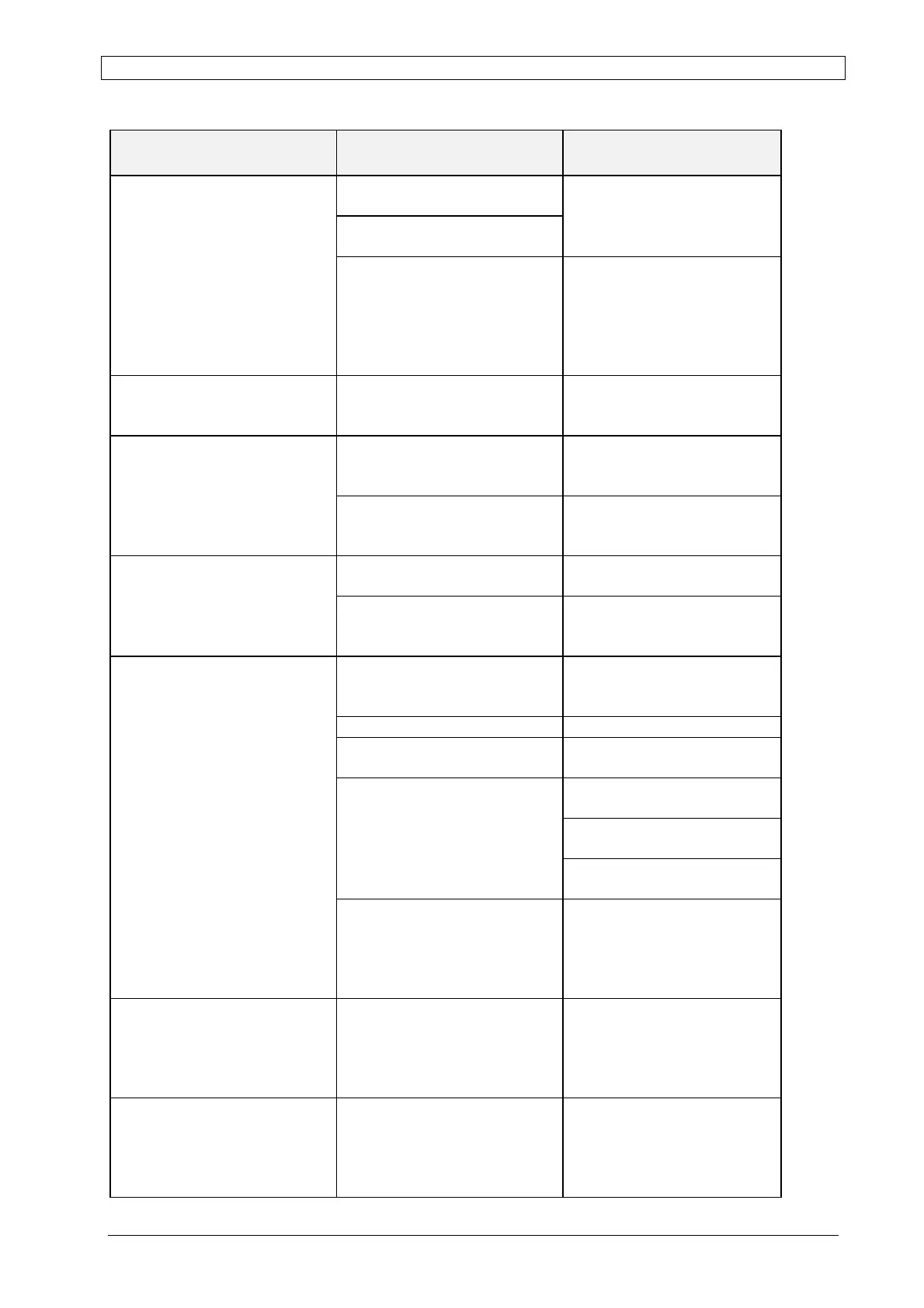

PROBLEM POSSIBLE CAUSE SOLUTION

Product detector loose or

vibrating.

Product detector alignment

or adjustment is marginal.

Refer to setup instructions

on page 57

Machine functions occur at

random without being

initiated.

Loose wiring connections. Check all wiring

connections. If necessary

request qualified

assistance. (Hotline

support, refer to page 13)

No label feed. Tamp home sensor is

broken or out of adjustment

(if a tamp is installed)

Replace or adjust sensor

as needed.

Blow time too short. Refer to the Setup

Instructions on page 85.

Air-Blast does not occur. (if

a tamp or blow-box

applicator is installed)

Air-Blast solenoid

malfunction.

Investigate and replace if

necessary.

No Air-Blast. See solutions above.

Label fails to leave the

tamp.

Too much vacuum (If blow-

box applicator is installed)

Reduce the vacuum by

closing slots.

Label is not detected by the

label sensor

Reload label material or

check position of the label

sensors (see page 41)

Label sensor is soiled Clean the label sensor

Incorrect

LABEL POSITION.

Check the setting (see

page 68)

Change to the correct

label format (s. page 64)

Calibrate the label sensor

(see page 73)

The selected LABEL-

FORMAT is not matching

to the used material

Calibrate the labels (see

page 74)

Label position is

consistently poor

Incorrect adjustment of the

label sensor or wrong

distance (for sensor-

peeling blade)

Examine the position of

the bracket (see Page 41)

or check parameter

setting of Address 0 05

(see page 79)

Loading...

Loading...