April 2010

3-19

Phaser 3635MFP/WorkCentre 3550

IQ17, IQ18

Image Quality

IQ17 Repeated Printing Defects Check RAP

Use this RAP when the printed image shows regular defects in black or white, across the pro-

cess direction.

Ensure the IQ1 Image Quality Entry RAP is performed before starting this RAP.

Procedure

WARNING

Switch off the electricity to the machine. Disconnect the power cord from the customer

supply while performing tasks that do not need electricity. Electricity can cause death or

injury. Moving parts can cause injury.

1. The xerographic drum may be contaminated, make 10 blank copies. If necessary, install a

new print cartridge,

PL 9.10 Item 1.

2. Measure the distance between the repeated black or white abnormality. Refer to Table 1

identify the possible cause.

3. Install new components as necessary.

4. If the defect appears to be fuser related, ensure that the paper tray settings match the

paper or media size in the trays.

IQ18 DADF Lead Edge Offset RAP

Use this RAP when copies from the DADF have lead edge offset.

Ensure the IQ1 Image Quality Entry RAP is performed before starting this RAP.

Procedure

WARNING

Switch off the electricity to the machine. Disconnect the power cord from the customer

supply while performing tasks that do not need electricity. Electricity can cause death or

injury. Moving parts can cause injury.

Refer to Wiring Diagram 10. Perform the following:

1. Open the DADF door assembly, PL 5.10 Item 3.

2. Check the document path for damage or obstructions.

3. Check that the DADF pick up rolls, PL 5.25 Item 2 are clean. If necessary, install a new

DADF pick up roll assembly, PL 5.25 Item 2.

4. Check that the following components are clean and rotate freely.

• Registration roll, PL 5.35 Item 9.

• Registration roll idlers, PL 5.15 Item 8.

5. Check that the registration sensor actuator, PL 5.35 Item 7 moves freely and is not dam-

aged.

6. Enter dC330 Component Control code 05-130. Check the registration sensor (Q05-130),

PL 5.35 Item 7. If necessary, install a new registration sensor.

7. If the defect is still present, install a new document transport assembly, PL 5.35 Item 14.

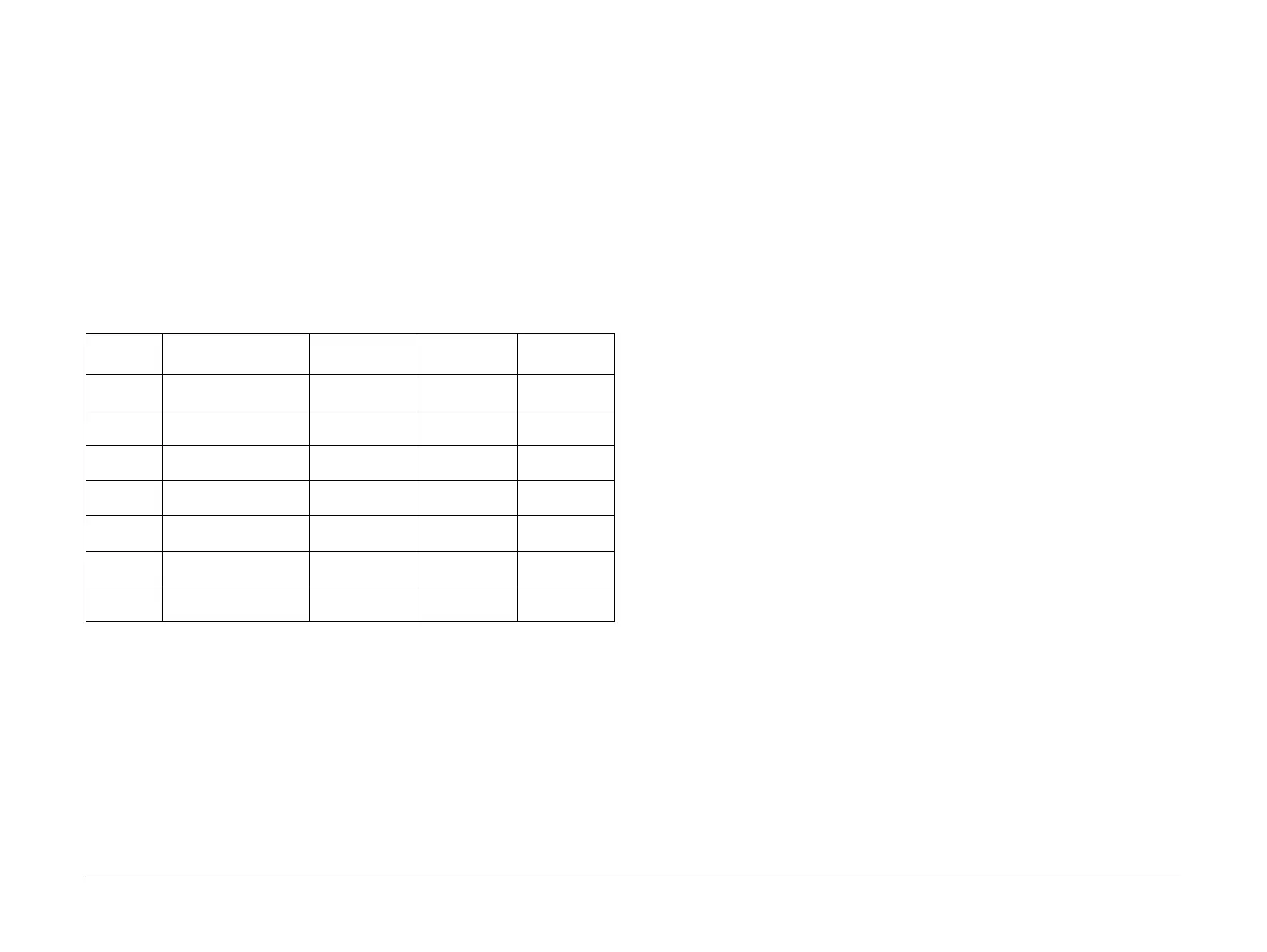

Table 1 Defect distance

Defect

distance

Kind of abnormal

image

Roll Component Parts List Ref.

95mm

(3.7 inches)

White spot. Black spot Xerographic drum Print cartridge PL 9.10 Item 1

38mm

(1.5 inches)

White spot. Black spot Charge roll Print cartridge PL 9.10 Item 1

45mm

(1.8 inches)

Horizontal dark band Supply roll Print cartridge PL 9.10 Item 1

47mm

(1.9 inches)

Black spot, White spot Transfer roll Transfer roll PL 9.10 Item 2

89mm

(3.5 inches)

Black spot, White spot Heat roll Fuser assembly PL 10.15 Item 1

51mm

(2 inches)

Back side contamination Pressure roll 1 Fuser assembly PL 10.15 Item 2

64mm

(2,5 inches)

Back side contamination Pressure roll 2 Fuser assembly PL 10.15 Item 3

Loading...

Loading...