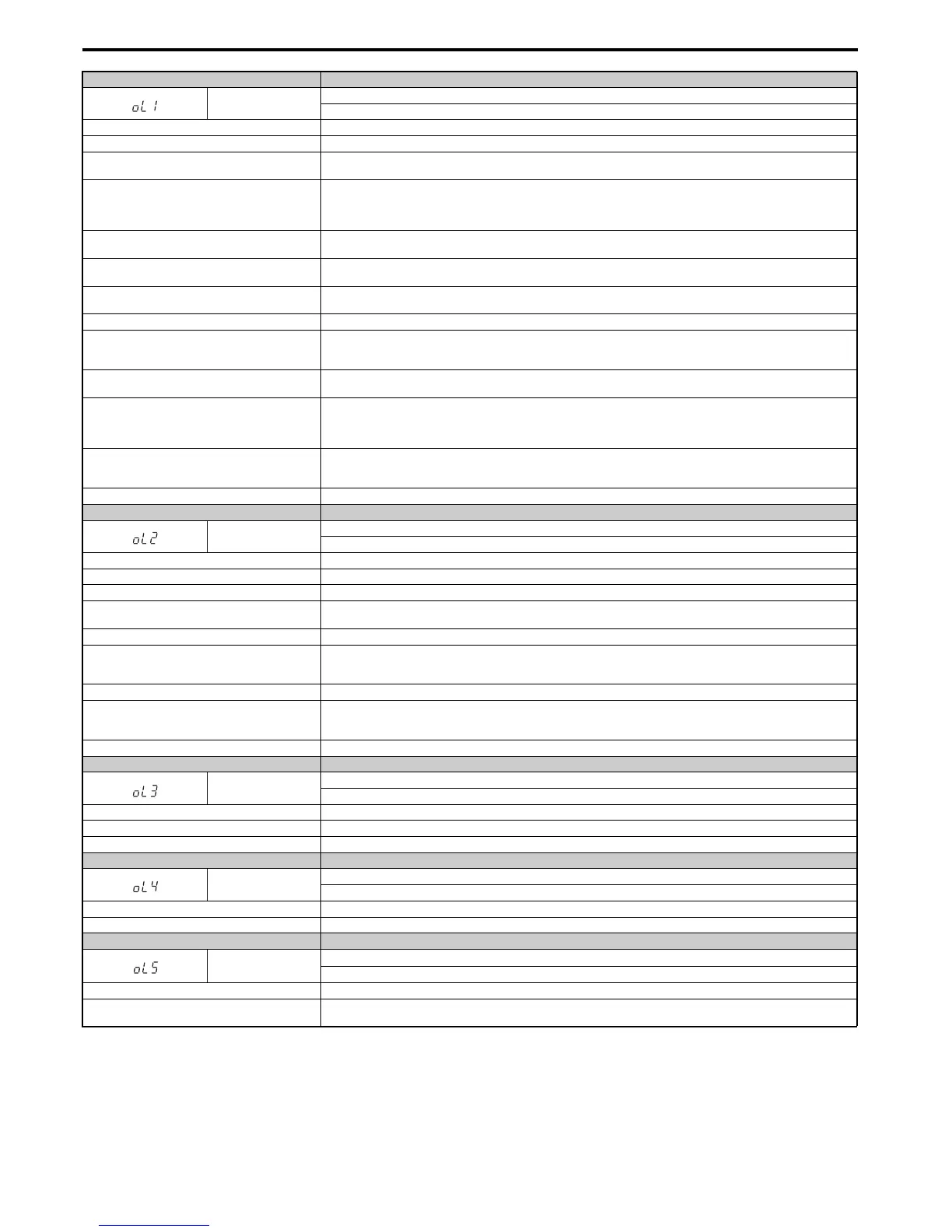

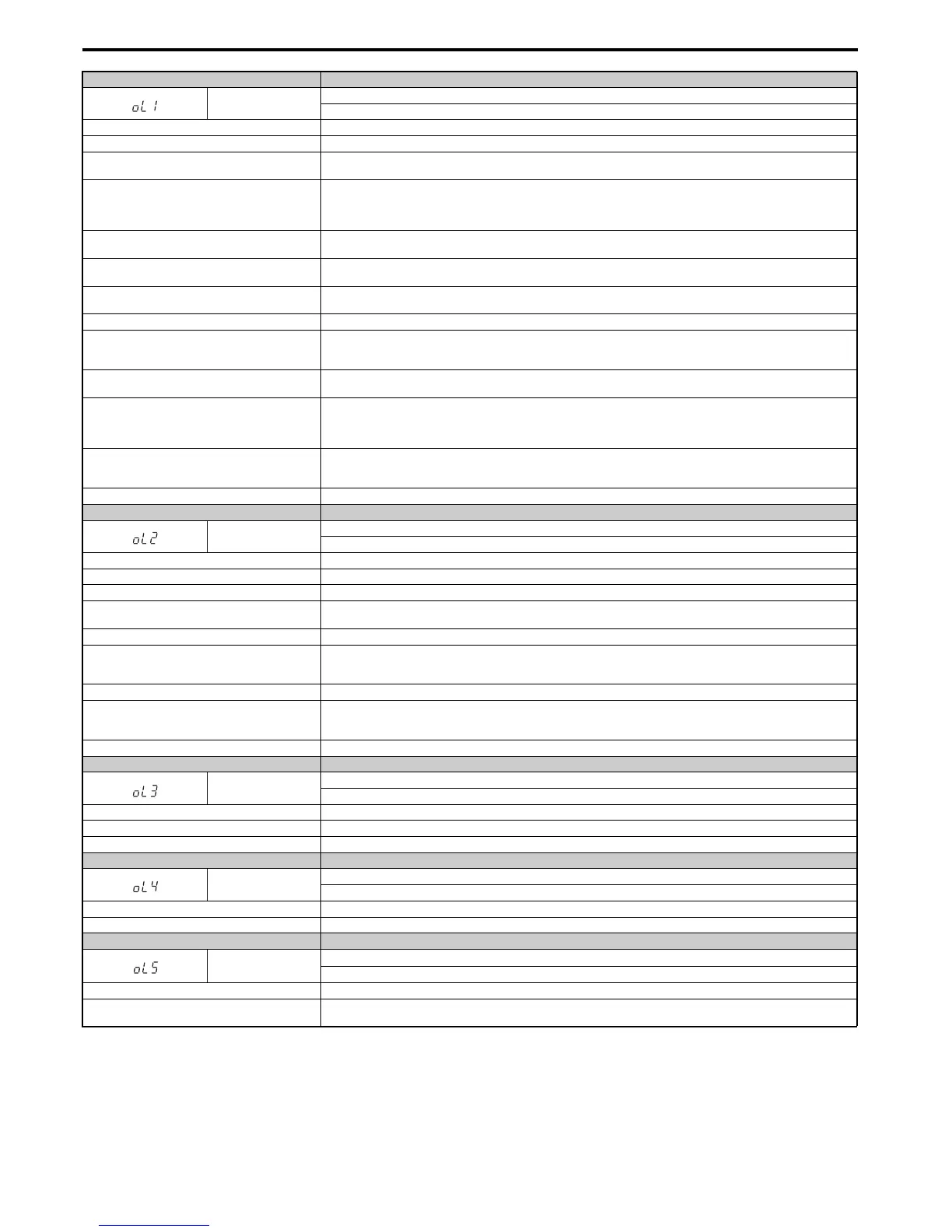

6.4 Fault Detection

314 YASKAWA ELECTRIC SIEP C710616 27C YASKAWA AC Drive A1000 Technical Manual

Digital Operator Display Fault Name

oL1

Motor Overload

The electronic motor overload protection tripped.

Cause Possible Solution

Load is too heavy. Reduce the load.

Cycle times are too short during acceleration and

deceleration.

Increase the acceleration and deceleration times (C1-01 through C1-08).

A general purpose motor is driven below the rated speed

with too high load.

• Reduce the load.

• Increase the speed.

• If the motor is supposed to operate at low speeds, either increase the motor capacity or use a motor specifically designed to

operate in the desired speed range.

The output voltage is too high.

Adjust the user-set V/f patterns (E1-04 through E1-10). Parameters E1-08 and E1-10 may need to be reduced. Be careful not to

lower E1-08 and E1-10 too much because this reduces load tolerance at low speeds.

The wrong motor rated current is set to E2-01.

• Check the motor-rated current.

• Enter the value written on the motor nameplate to parameter E2-01.

The maximum output frequency is set incorrectly.

• Check the rated frequency indicated on the motor nameplate.

• Enter the rated frequency to E1-06 (Base Frequency).

Multiple motors are running off the same drive. Disable the motor protection function (L1-01 = 0) and install a thermal relay to each motor.

The electrical thermal protection characteristics and

motor overload characteristics do not match.

• Check the motor characteristics.

• Correct the type of motor protection that has been selected (L1-01).

• Install an external thermal relay.

The electrical thermal relay is operating at the wrong

level.

• Check the current rating listed on the motor nameplate.

• Check the value set for the motor rated current (E2-01).

Motor overheated by overexcitation operation.

• Overexcitation increases the motor losses and the motor temperature. If applied too long, motor damage can occur. Prevent

excessive overexcitation operation or apply proper cooling to the motor.

• Reduce the excitation deceleration gain (n3-13).

• Set L3-04 (Stall Prevention during Deceleration) to a value other than 4.

Speed Search related parameters are set incorrectly.

• Check values set to Speed Search related parameters.

• Adjust the Speed Search current and Speed Search deceleration times (b3-02 and b3-03 respectively).

• After Auto-Tuning, enable Speed Estimation Speed Search (b3-24 = 1).

Output current fluctuation due to input phase loss Check the power supply for phase loss.

Digital Operator Display Fault Name

oL2

Drive Overload

The thermal sensor of the drive triggered overload protection.

Cause Possible Solution

Load is too heavy. Reduce the load.

Acceleration or deceleration times are too short. Increase the settings for the acceleration and deceleration times (C1-01 through C1-08).

The output voltage is too high.

• Adjust the preset V/f pattern (E1-04 through E1-10). This will mainly involve reducing E1-08 and E1-10.

• Be careful not to lower E1-08 and E1-10 excessively because this reduces load tolerance at low speeds.

Drive capacity is too small. Replace the drive with a larger model.

Overload occurred when operating at low speeds.

• Reduce the load when operating at low speeds.

• Replace the drive with a model that is one frame size larger.

• Lower the carrier frequency (C6-02).

Excessive torque compensation. Reduce the torque compensation gain (C4-01) until there is no speed loss but less current.

Speed Search related parameters are set incorrectly.

• Check the settings for all Speed Search related parameters.

• Adjust the current used during Speed Search and the Speed Search deceleration time (b3-03 and b3-02 respectively).

• After Auto-Tuning the drive, enable the Speed Estimation Speed Search (b3-24 = 1).

Output current fluctuation due to input phase loss Check the power supply for phase loss.

Digital Operator Display Fault Name

oL3

Overtorque Detection 1

The current has exceeded the value set for torque detection (L6-02) for longer than the allowable time (L6-03).

Cause Possible Solution

Parameter settings are not appropriate for the load. Check the settings of parameters L6-02 and L6-03.

Fault on the machine side (e.g., machine is locked up). Check the status of the load. Remove the cause of the fault.

Digital Operator Display Fault Name

oL4

Overtorque Detection 2

The current has exceeded the value set for Overtorque Detection 2 (L6-05) for longer than the allowable time (L6-06).

Cause Possible Solution

Parameter settings are not appropriate for the load. Check the settings of parameters L6-05 and L6-06.

Digital Operator Display Fault Name

oL5

Mechanical Weakening Detection 1

Overtorque occurred, matching the conditions specified in L6-08.

Cause Possible Solution

Overtorque triggered mechanical weakening detection

level set to L6-08.

Check for the cause of mechanical weakening.

Loading...

Loading...