3.8 Main Circuit Wiring

70 YASKAWA ELECTRIC SIEP C710616 27C YASKAWA AC Drive A1000 Technical Manual

◆ Main Circuit Terminal and Motor Wiring

This section outlines the various steps, precautions, and checkpoints for wiring the main circuit terminals and motor

terminals.

NOTICE: When connecting the motor to the drive output terminals U/T1, V/T2, and W/T3, the phase order for the drive and motor

should match. Failure to comply with proper wiring practices may cause the motor to run in reverse if the phase order is backward.

NOTICE: Do not connect phase-advancing capacitors or LC/RC noise filters to the output circuits. Failure to comply could result in

damage to the drive, phase-advancing capacitors, LC/RC noise filters or ground fault circuit interrupters.

NOTICE: Do not connect the AC power line to the output motor terminals of the drive. Failure to comply could result in death or serious

injury by fire as a result of drive damage from line voltage application to output terminals.

■ Cable Length Between Drive and Motor

Voltage drop along the motor cable may cause reduced motor torque when the wiring between the drive and the motor is

too long, especially at low frequency output. This can also be a problem when motors are connected in parallel with a

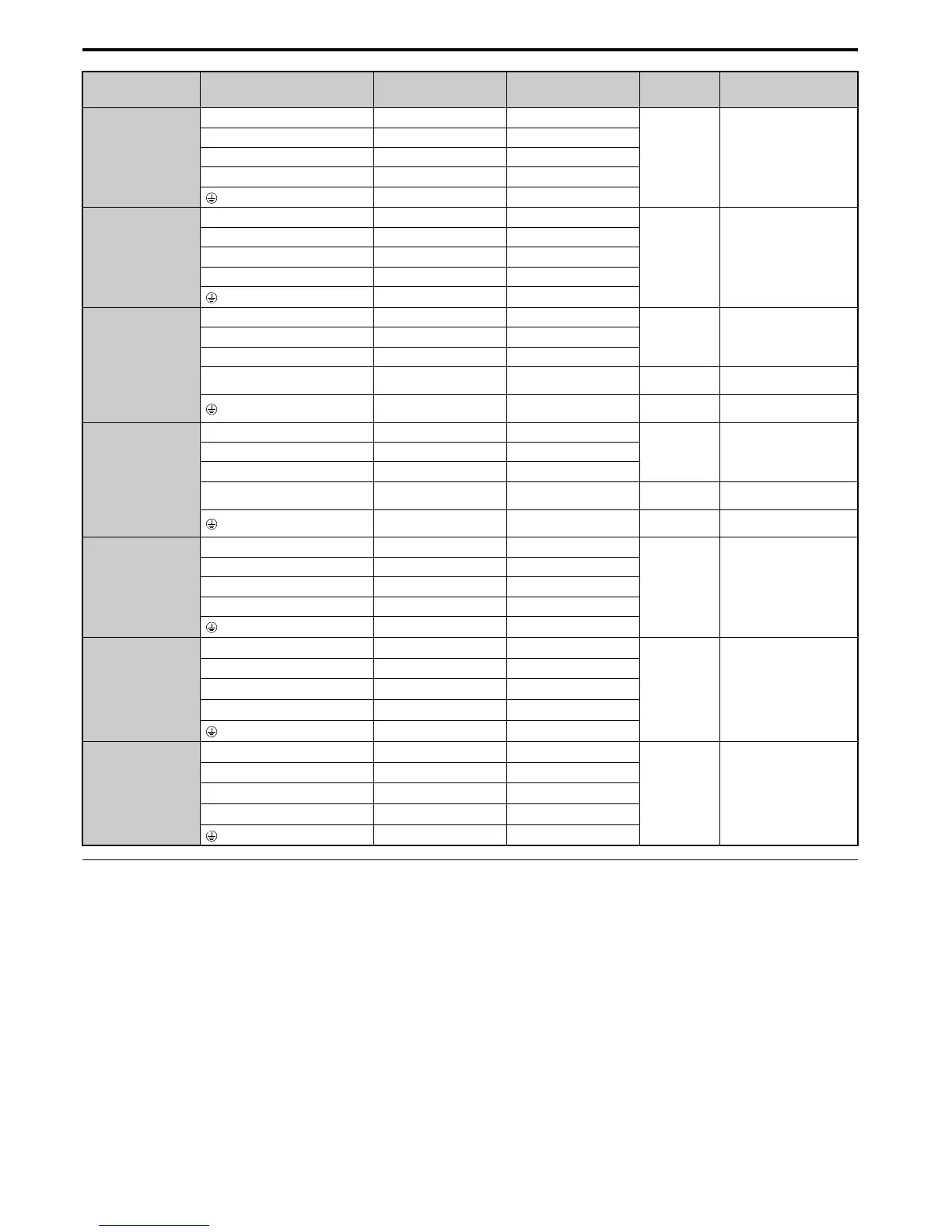

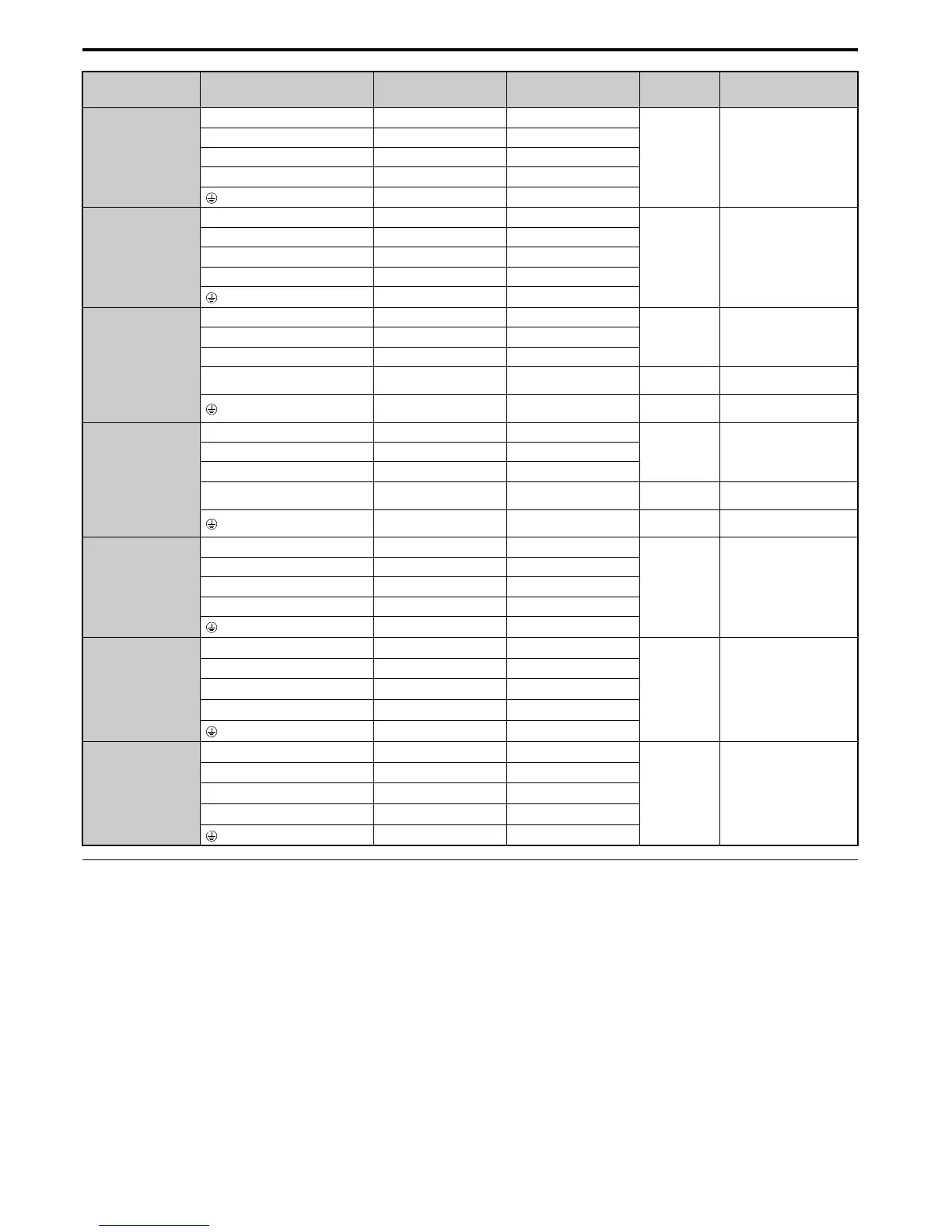

4A0208

R/L1, S/L2, T/L3 95 35 to 95

M10

18 to 23

(159 to 204)

U/T1, V/T2, W/T3 95 35 to 95

–, +1 – 35 to 150

+3 – 25 to 70

50 50 to 150

4A0250

R/L1, S/L2, T/L3 120 95 to 300

M10

18 to 23

(159 to 204)

U/T1, V/T2, W/T3 120 95 to 300

–, +1 – 70 to 300

+3 – 35 to 300

70 70 to 240

4A0296

R/L1, S/L2, T/L3 185 95 to 300

M12

32 to 40

(283 to 354)

U/T1, V/T2, W/T3 185 95 to 300

–, +1 – 70 to 300

+3 – 35 to 300 M10

18 to 23

(159 to 204)

95 95 to 240 M12

32 to 40

(283 to 354)

4A0362

R/L1, S/L2, T/L3 240 95 to 300

M12

32 to 40

(283 to 354)

U/T1, V/T2, W/T3 240 95 to 300

–, +1 – 95 to 300

+3 – 70 to 300 M10

18 to 23

(159 to 204)

120 120 to 240 M12

32 to 40

(283 to 354)

4A0414

R/L1, S/L2, T/L3 95 × 2P 95 to 150

M12

32 to 40

(283 to 354)

U/T1, V/T2, W/T3 95 × 2P 95 to 150

–, +1 – 70 to 150

+3 – 70 to 150

95 35 to 95

4A0515

R/L1, S/L2, T/L3 120 × 2P 95 to 150

M12

32 to 40

(283 to 354)

U/T1, V/T2, W/T3 150 × 2P 95 to 150

–, +1 – 70 to 150

+3 – 70 to 150

150 50 to 150

4A0675

R/L1, S/L2, T/L3 95 × 4P 95 to 150

M12

32 to 40

(283 to 354)

U/T1, V/T2, W/T3 95 × 4P 95 to 150

–, +1 – 70 to 150

+3 – 70 to 150

95 × 2P 60 to 150

Model

CIMR-A

Terminal

Recommended Gauge

mm

2

Applicable

Gauge

mm

2

Screw

Size

Tightening

Torque

Nxm (lb.in.)

Loading...

Loading...