98 YASKAWA ELECTRIC SIEP C710616 27C YASKAWA AC Drive A1000 Technical Manual

4.4 Start-Up Flowcharts

4.4 Start-Up Flowcharts

The flowcharts in this section summarize basic steps required to start the drive. Use the flowcharts to determine the most

appropriate start-up method for a given application. The charts are intended as a quick reference to help familiarize the

user with start-up procedures.

Note: To set up the drive using one of the Application Presets, refer to Application Selection on page 103.

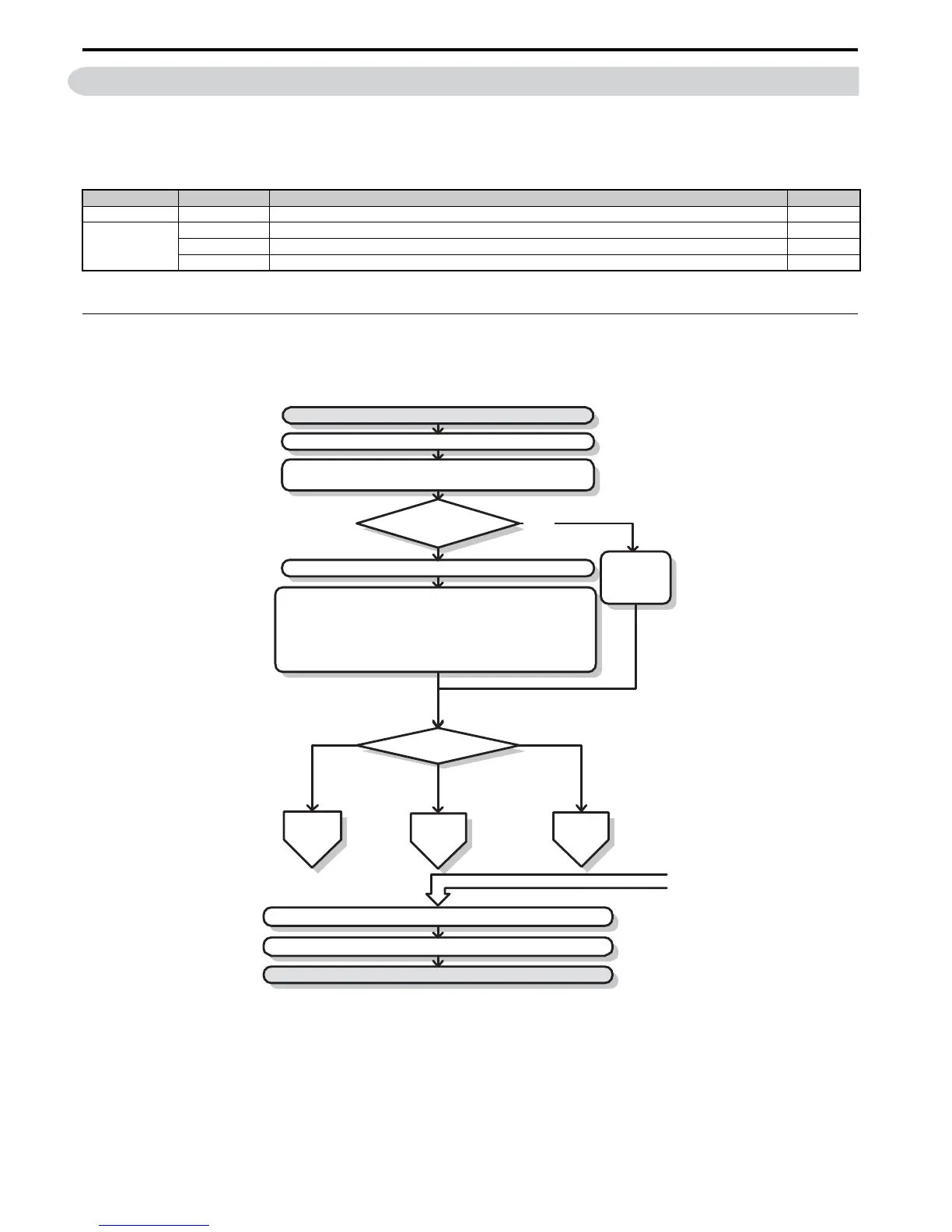

◆ Flowchart A: Basic Start-up and Motor Tuning

Flowchart A in Figure 4.8 describes a basic start-up sequence. This sequence varies slightly depending on the

application. Use drive default parameter settings in simple applications that do not require high precision.

Figure 4. 7

Figure 4.8 Basic Start-up

Note: When the motor cable length has changed for more than 50 m after Auto-Tuning has been performed (e.g., after the drive has

been set up and then later installed in a different location), execute Stationary Auto-Tuning for resistance between motor lines

once the drive is installed in its final installation location.

Note: Auto-Tuning should be performed again after installing an AC reactor or other such components to the output side of the drive.

Flowchart Subchart Objective Page

A – Basic startup procedure and motor tuning 98

–

A-1 Simple motor setup using V/f mode 99

A-2 High-performance operation using Open Loop Vector (OLV) or Closed Loop Vector (CLV) motor control 100

A-3 Setting up the drive to run a permanent magnet (PM) motor 101

YES

NO

START

Install and wire the drive as explained in Chapters 1, 2, and 3

Apply main power on to the drive

Adhere to safety messages concerning application of power

Application Presets

A1-06 used ?

Set the control mode in parameter A1-02.

Refer to

Application

Selection section

To

Flowchart A-1

Control Mode

A1-02 =

To

Flowchart A-2

To

Flowchart A-3

Set the basic parameters

b1-01/02 for frequency reference and run command source selection

H1-, H2-, H3-, H4-, H6- for I/O terminal setting

d1- for multi-speed references if used

C1- and C2- for accel./decel. and S-curve time settings

C6-01 for heavy/normal duty mode selection

L8-55 = 0 if a regen converter is used.

L3-04 if dynamic braking options are used

Fine tune parameters. Adjust application settings (PID, ...) if necessary.

Check the machine operation and verify parameter settings.

Drive is ready to run the application.

From Flowchart A-1, A-2, or A-3

0: V/f

1: V/f w/PG

2: OLV

3: CLV

5: OLV/PM

6: AOLV/PM

7: CLV/PM

Loading...

Loading...